Pressing mechanism of ICT testing fixture

A technology of test fixtures and pressure plates, which is applied in the direction of the measuring device shell, etc., can solve the problems of not being able to meet the needs of the test, the trouble of picking and placing the PCB board, and the low test efficiency, so as to achieve good test results, easy operation and fast speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

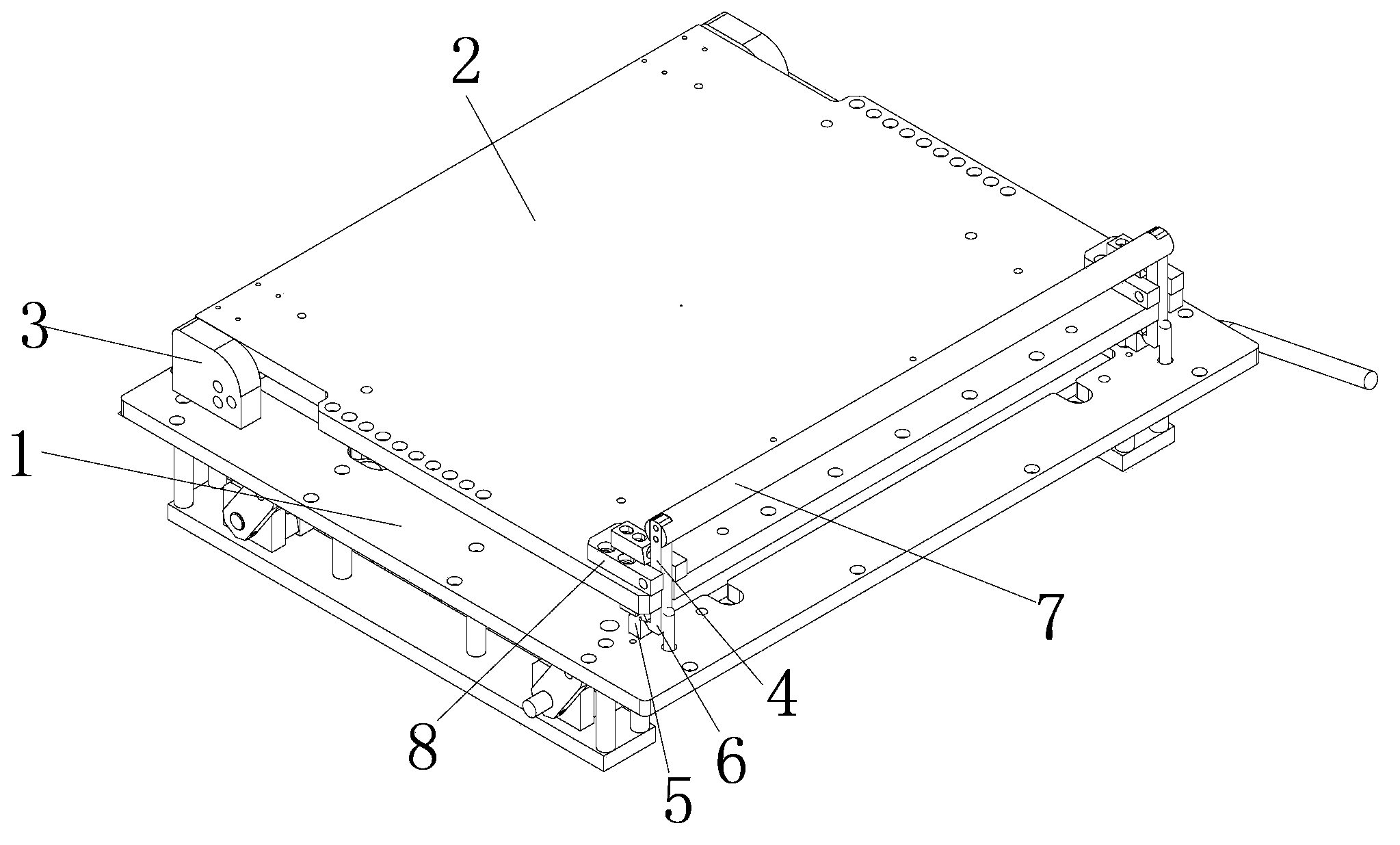

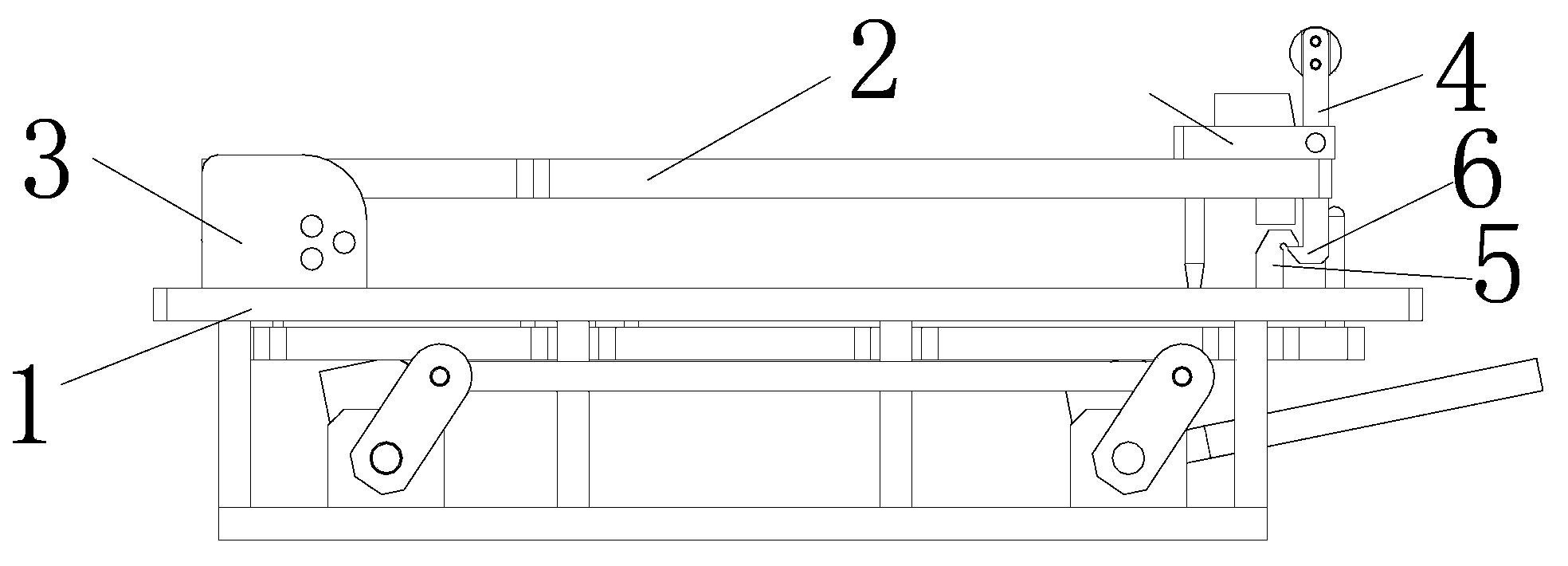

[0013] like Figure 1-2 As shown, a pressing mechanism for an ICT test fixture includes a carrier plate 1, a pressure plate 2, a hinge seat 3, a rotating shaft 4, a pull rod 7, an upper hook angle 5 and a lower hook angle 6, and the rear end of the carrier plate 1 is provided with Two hinge seats 3, the rear end of the pressing plate 2 is movably connected between the two hinge seats 3, two openings for passing through the rotating shaft 4 are arranged at the front end of the pressing plate 2, and the rotating shaft 4 is connected with the pressing plate 2. The side walls are movably connected. Two limit seats 8 are arranged on the pressure plate 2. An opening is provided at the front end of the limit seat 8. The rotating shaft 4 on the corresponding side passes through the opening of the limit seat 8. The rotating shaft 4 passes through the positioning pin The articu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap