Laser tracker based method for achieving optical system axis through and center alignment

A laser tracker and optical system technology, applied in optics, optical components, optical devices, etc., can solve the problems of reduced precision, cumbersome operation procedures, low efficiency, etc., to improve work efficiency and precision, avoid complicated processes, operations, etc. Simple and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

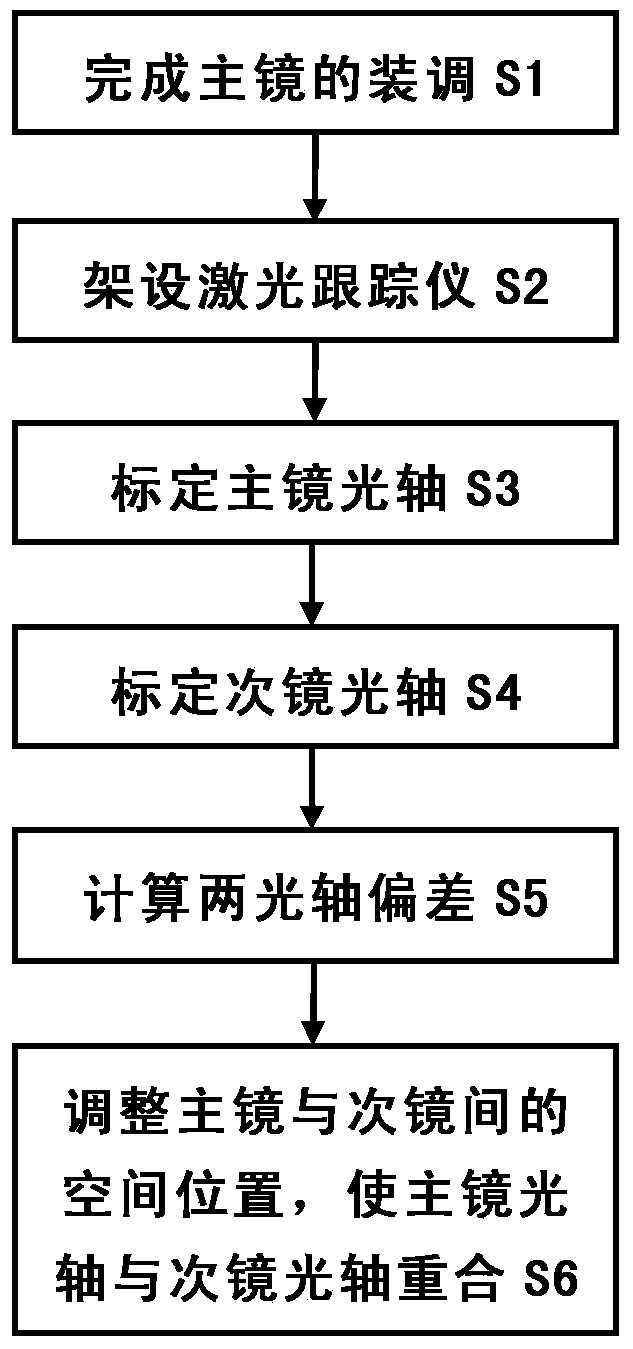

[0018] Such as figure 1 It shows the flow of the method of centering the optical system through the axis based on the laser tracker, and the method is completed through the following steps:

[0019] Step S1: Assemble and adjust the primary mirror and secondary mirror of the optical system.

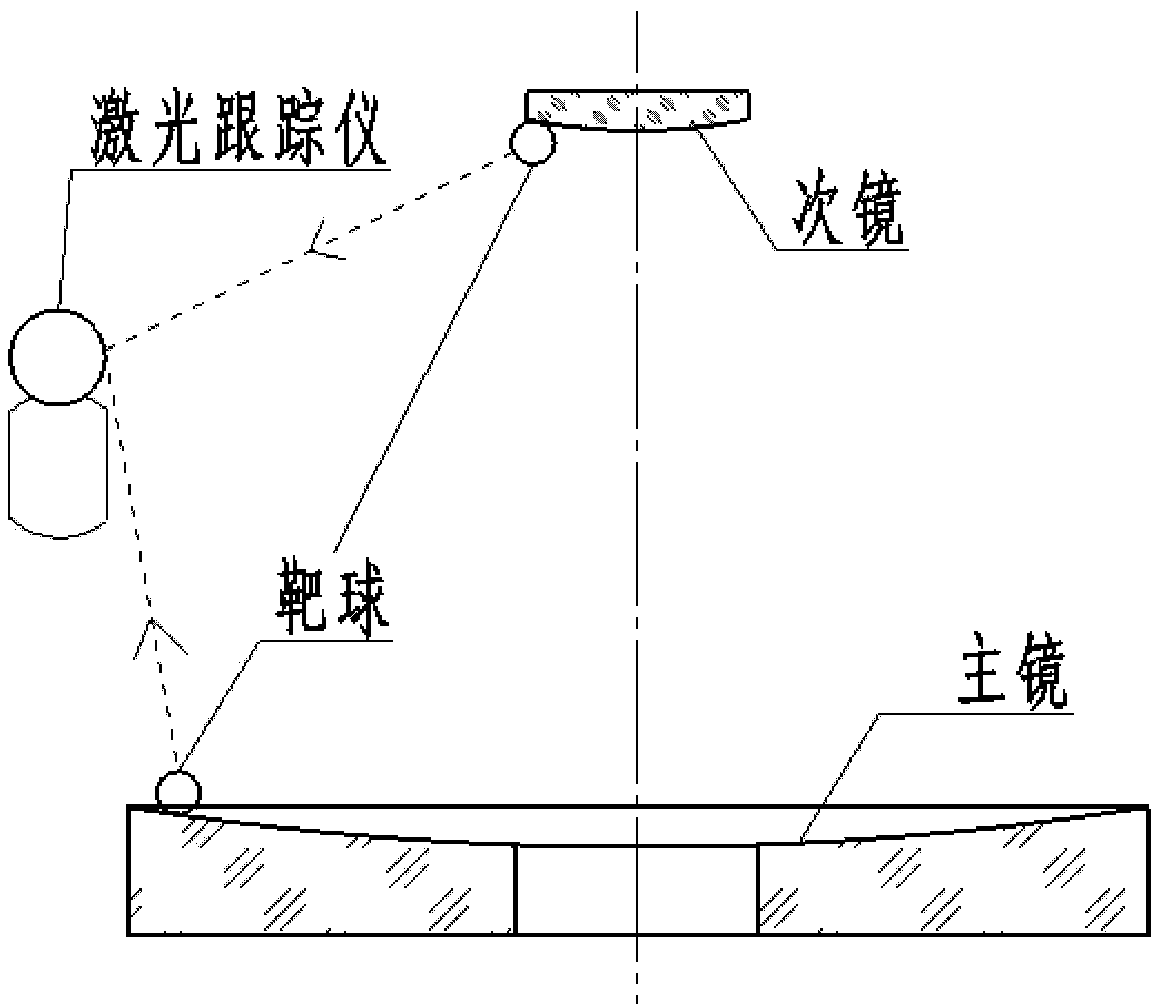

[0020] Step S2: Set up the laser tracker. Set up the laser tracker at a position where the primary mirror and the secondary mirror can be measured at the same time, and ensure that the laser tracker is stable.

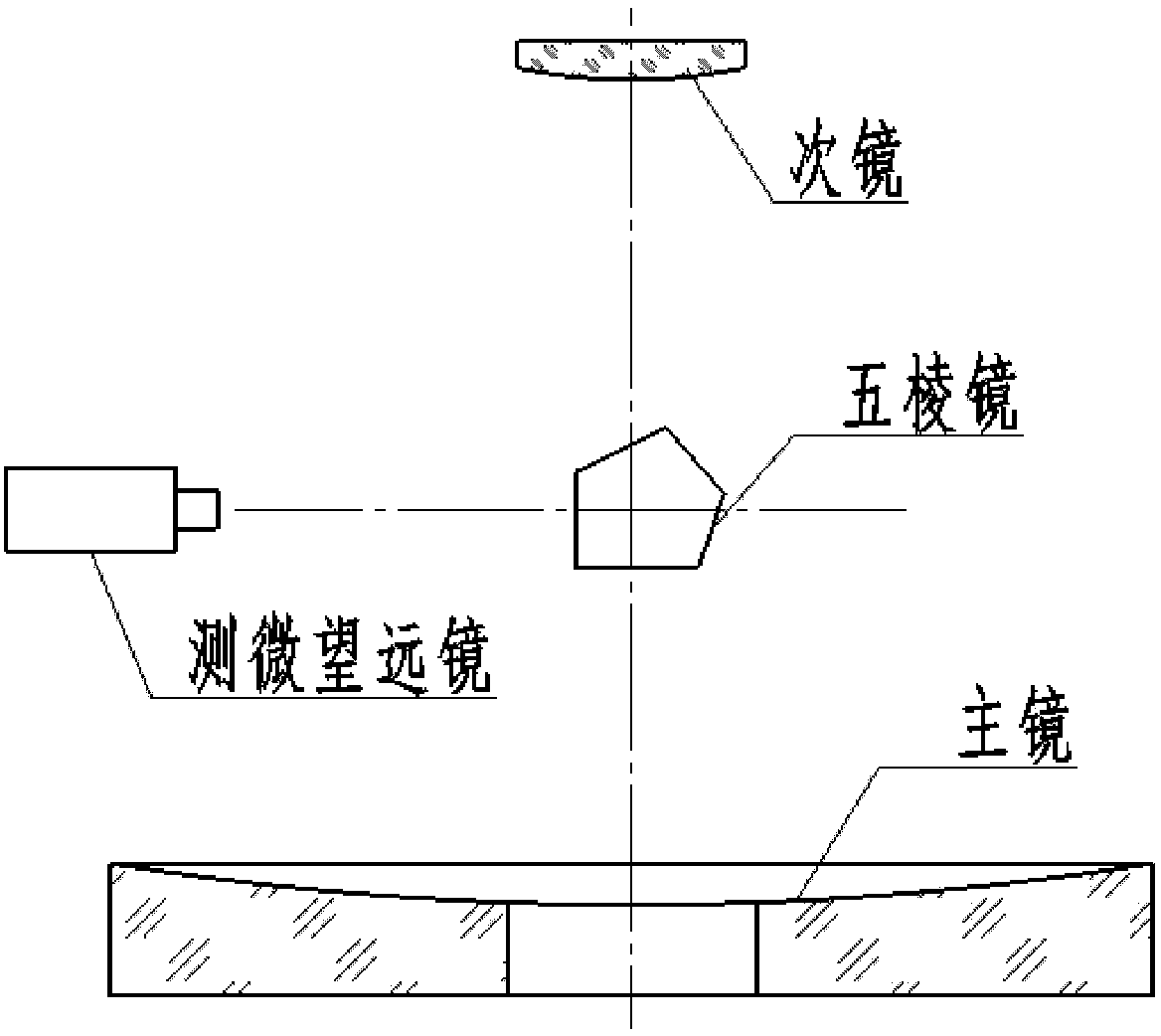

[0021] Step S3: Move the target ball on the primary mirror, and use the laser tracker to calibrate the optical axis of the primary mirror. The target ball moves on the primary mirror, and the laser tracker is used to measure the moving space trajectory of the target ball, and the spatial geometric characteristics of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com