Non-contact type fluid flow measuring system and method based on Lamb waves

A fluid flow, non-contact technology, used in liquid/fluid solid measurement, measurement flow/mass flow, measurement devices, etc., can solve problems such as time-consuming, complicated, allergic reactions, etc., to improve accuracy and signal strength. , the effect of saving manpower and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

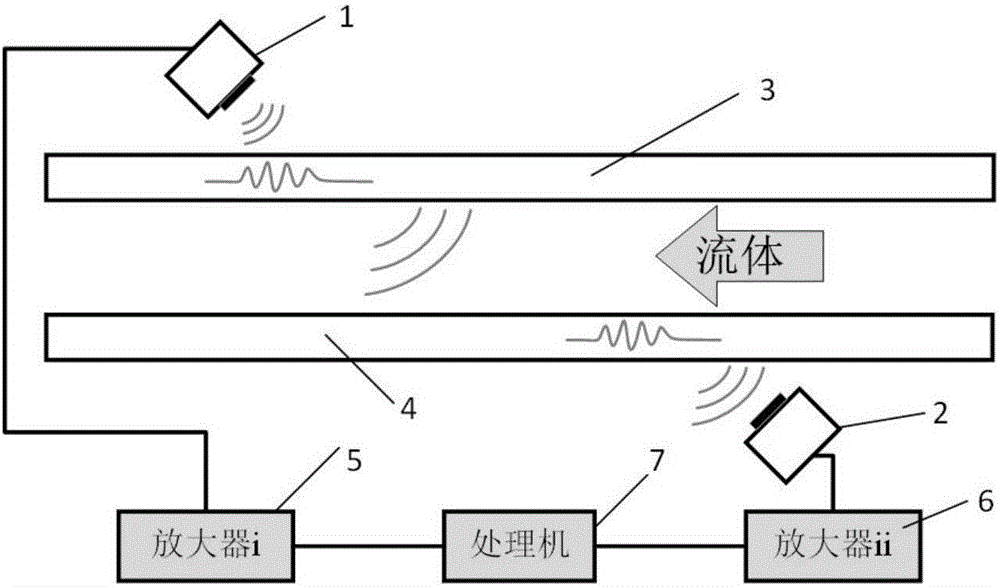

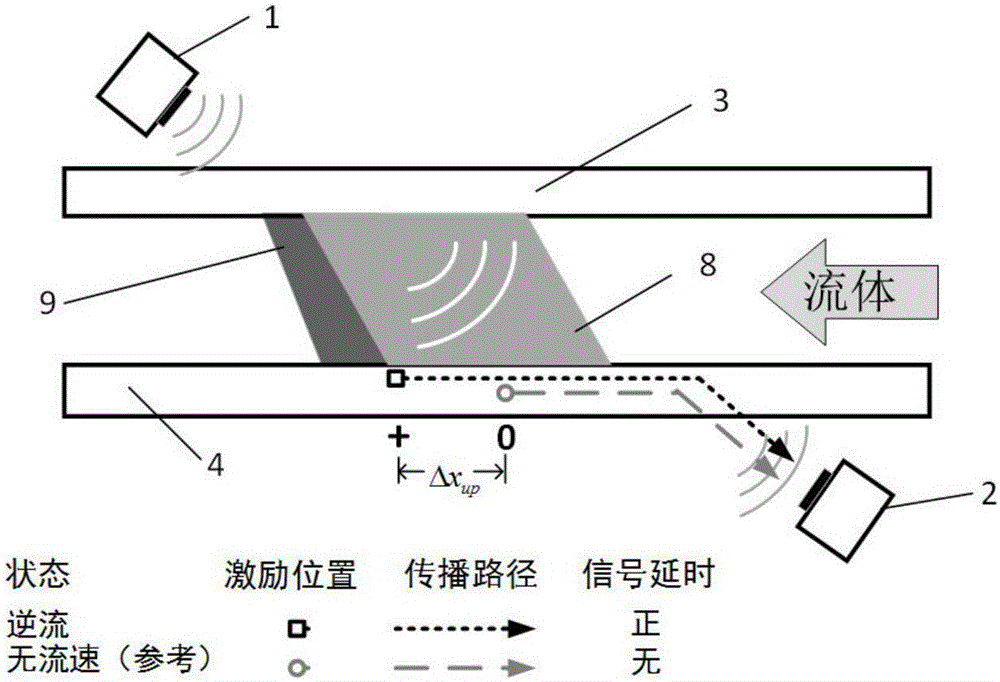

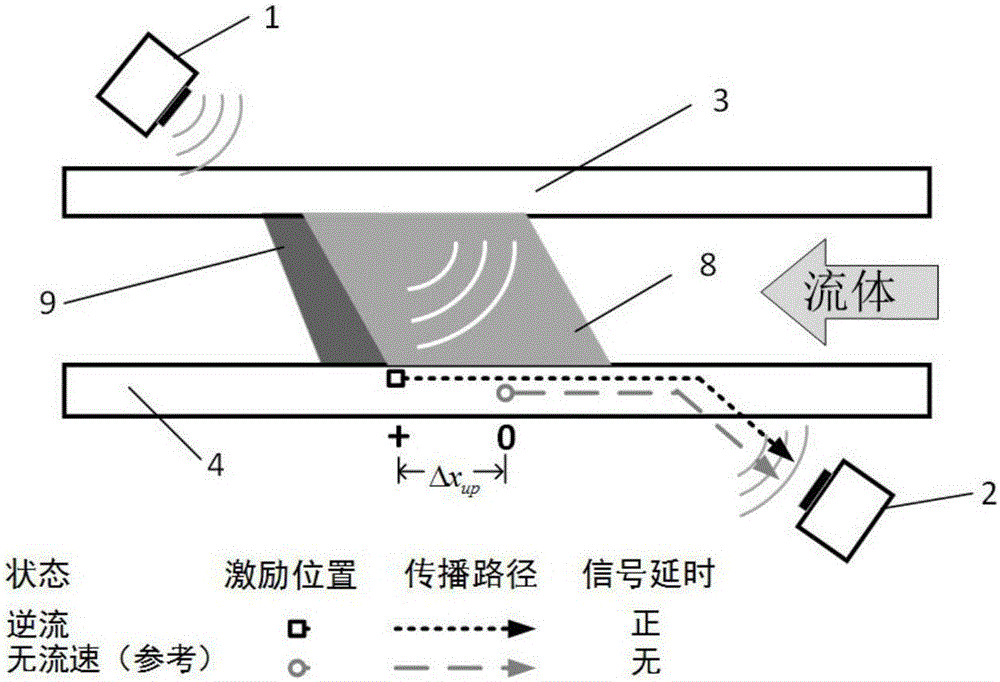

[0026] The present invention will be further described below in conjunction with accompanying drawing and embodiment: figure 1 It is a schematic diagram of the principle of the present invention; figure 2 It is a schematic diagram of the measurement signal delay principle of the present invention under countercurrent conditions; image 3 It is a schematic diagram of the measurement signal delay principle in the downstream condition of the present invention.

[0027] Such as figure 1 As shown, the non-contact fluid flow measurement system based on Lamb waves in this embodiment includes transducer I1, transducer II2 and a processor, and the transducer I1 and transducer II2 are respectively arranged in the pipeline under test The external side is on the opposite side and the working surface is not in contact with the pipe under test. The working surface refers to the surface of the transducer transmitting end or receiving end. Transducer Ⅰ1 is used as the ultrasonic transmitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com