Image sensor and manufacturing method of image sensor

A technology of an image sensor and a manufacturing method, which is applied in the field of semiconductors, can solve the problems of low transmission efficiency of photogenerated carriers, achieve high transmission rate and improve transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In existing image sensors, since the floating diffusion region is a heavily doped region, the transmission efficiency of photogenerated carriers is limited, and the transmission efficiency of photogenerated carriers is low.

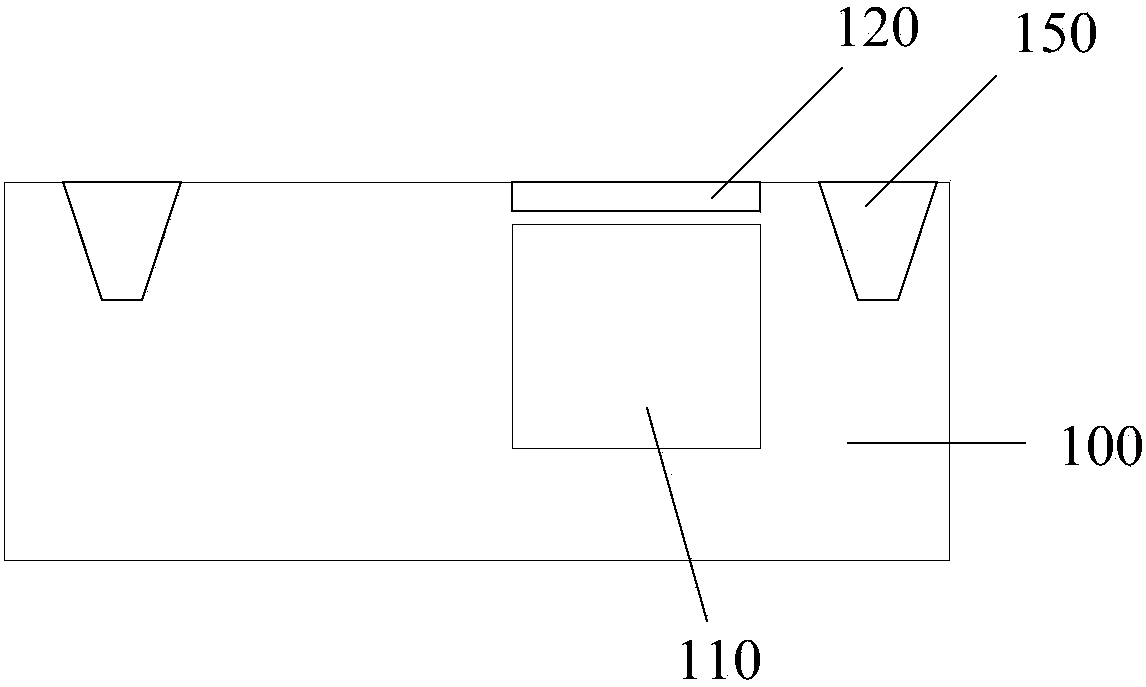

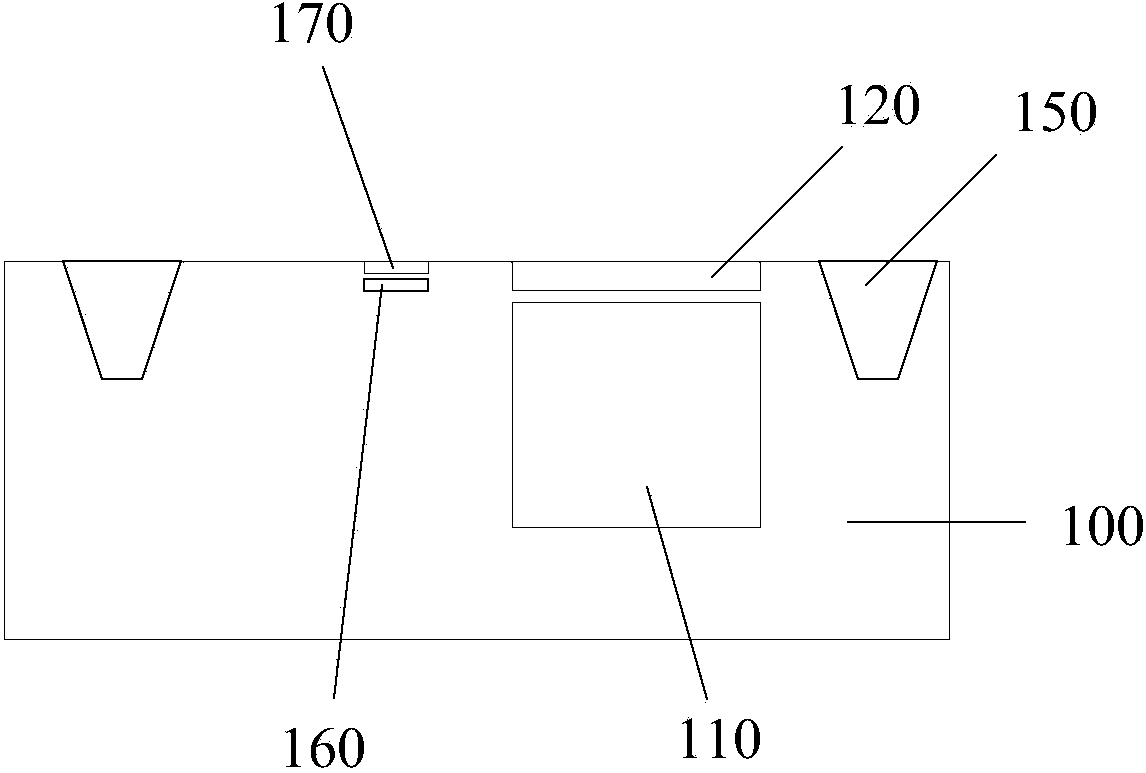

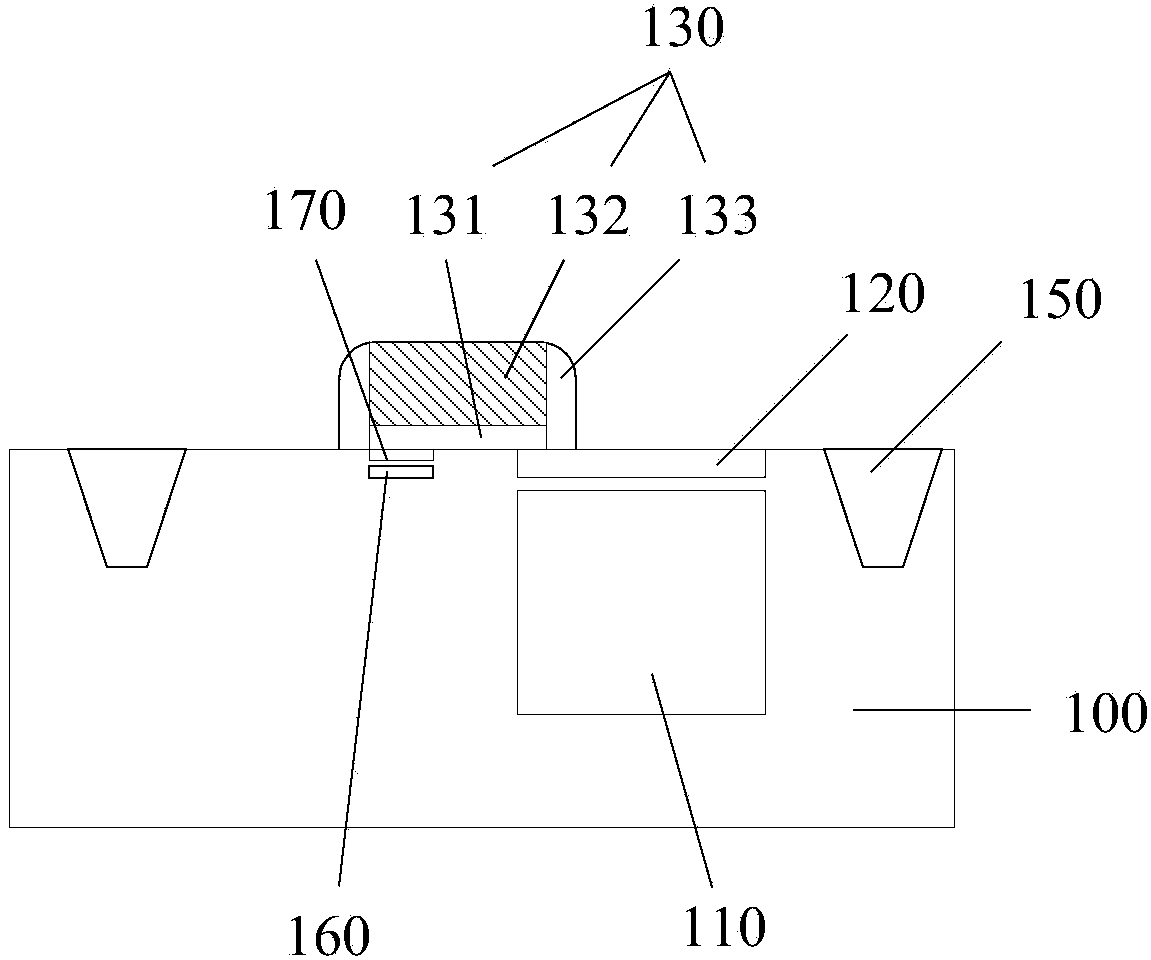

[0038] To this end, the present invention provides an image sensor. The image sensor is provided with a lightly doped region of the second conductivity type in the semiconductor substrate of the first conductivity type under the gate, and the lightly doped region of the second conductivity type In contact with the floating diffusion region, the lightly doped region of the second conductivity type is equivalent to the epitaxial part of the floating diffusion region, so that when the photogenerated carriers are transported in the channel, they are easily absorbed by the second conductive type due to the potential in the transmission channel. Type doped region and its adjacent floating diffusion region attract, the transport rate of photogenerated carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com