PCB buffering and locating hot-pressing fixture

A PCB board and jig technology, applied in the field of PCB board buffer positioning hot pressing fixture, can solve the problems of low heating accuracy, crushed platen, no positioning system, etc., and achieves high processing accuracy, long service life, and guaranteed processing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

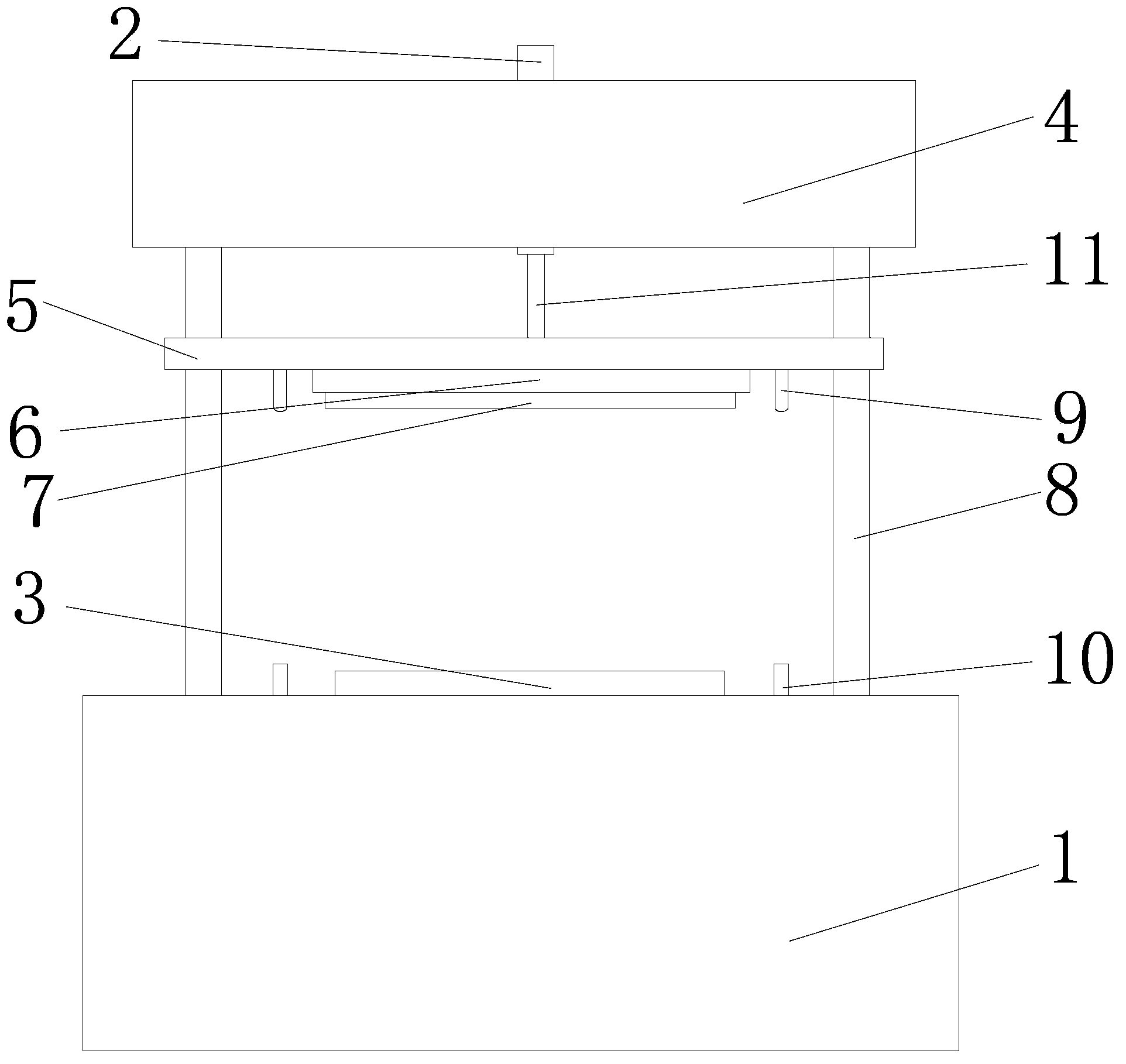

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a PCB board cushioning and positioning hot pressing fixture includes a hot pressing table 1, a cylinder 2, a carrier plate 3, a frame 4, a pressing plate 5, a cushion plate 6, a heating plate 7, a guide post 8, and a positioning pin 9 and positioning seat 10, a carrier plate 3 for placing hot-pressed parts is provided on the top of the hot-pressing table 1, a frame 4 is arranged above the hot-pressing table 1, and two The guide posts 8 parallel to each other are provided with a cylinder 2 in the frame 4, the bottom of the cylinder rod 11 of the cylinder 2 is connected with a pressing plate 5, and the pressing plate 5 passes through the guide posts 8 and can move up and down along the guide posts 8, The bottom of the pressing plate 5 is provided with a buffer pad 6, a heating plate 7 is arranged under the buffer pad 6, a heating chip i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com