Iron base soft magnetic powder for powder magnetic core, fabrication method for same, and powder magnetic core

A powder magnetic core and soft magnetic technology, which is applied to the iron-based soft magnetic powder for powder magnetic core and the manufacture of iron-based soft magnetic powder for the powder magnetic core and the field of powder magnetic core, which can solve the problems of high cost and achieve improved durability. Thermal properties, low iron loss, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

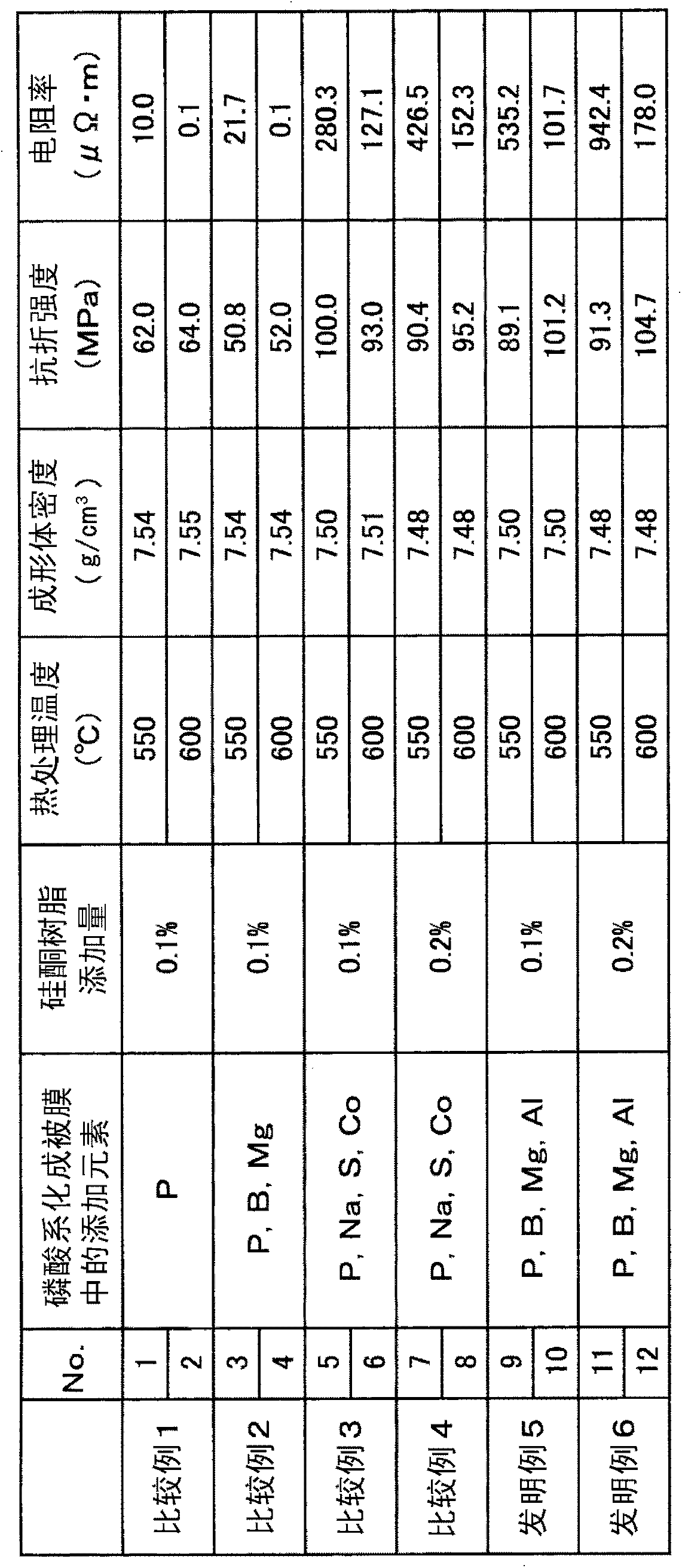

[0023] The present inventors formed a powder compact of an iron-based soft magnetic powder base material on which a coating film composed of only phosphoric acid or a glassy insulating layer obtained from phosphoric acid described in Patent Document 1 was formed, and obtained a pressed powder. Powder shaped body (powder core). Furthermore, the present inventors measured the electrical resistivity (μΩ·m) of the powder compact by changing the temperature. As a result, in all cases, it was confirmed that the resistivity of the compact was lowered to about 10 μΩ·m by the treatment at 450° C. (under a nitrogen atmosphere, for 1 hour).

[0024] The inventors of the present invention studied the cause of the decrease in resistivity, and as a result, it is speculated that oxygen atoms derived from phosphoric acid contained in the phosphoric acid-based film diffused during heat treatment at a high temperature and bonded to Fe to form oxidation of Fe that functions as a semiconductor. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com