Active daylighting and solidified soil independent heat storage rear wall sunlight greenhouse

A technology for a solar greenhouse and solidifying soil, applied in a field, can solve the problems of improving the thermal insulation performance of the solar greenhouse, the heat storage performance of the greenhouse is not much improved, and the complexity of the heat storage problem of the rear wall, etc. The effect is good and the processing cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

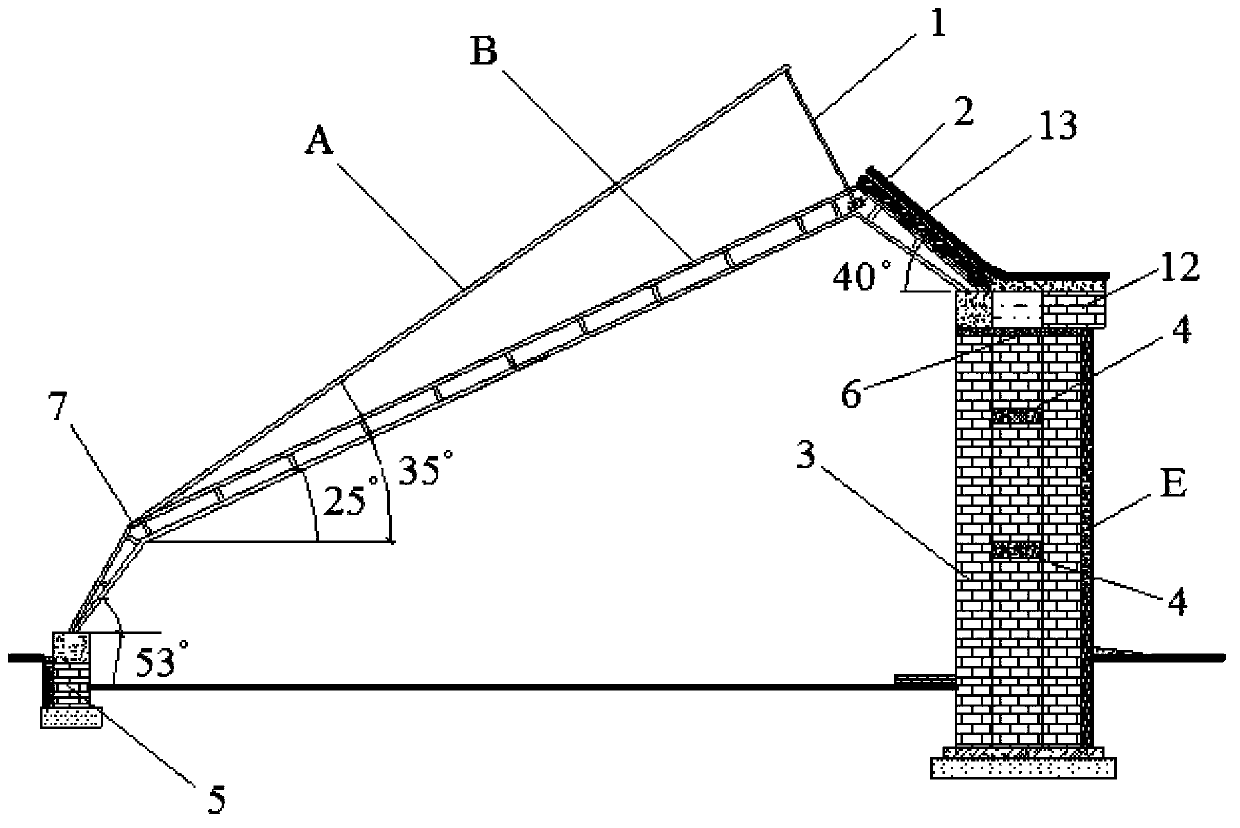

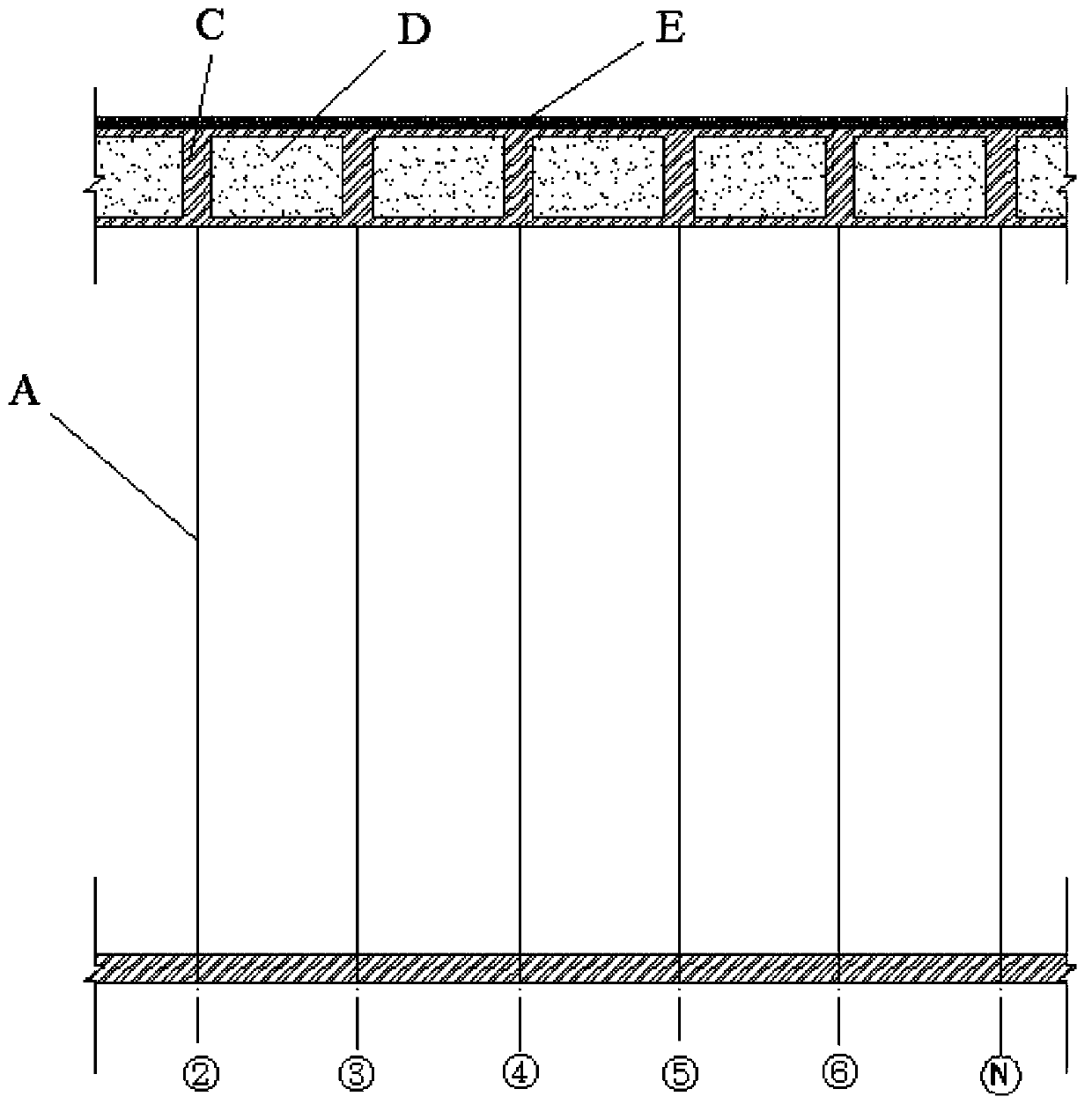

[0026] see Figure 1 ~ Figure 4 , the present embodiment provides a kind of active daylighting and solidified soil self-storage rear wall solar greenhouse, including the front wall 5 and the rear wall 3 exposed to the ground, there is a roof between the front wall 5 and the rear wall 3; the roof consists of The movable framework A and the fixed framework B are composed, the movable framework A and the fixed framework B are fixed between the front wall 5 and the rear wall 3, the fixed framework B is installed on the front wall 5, and the angle between the fixed framework B and the front wall 5 is 53° , the angle between the fixed frame B and the horizontal plane is 25°.

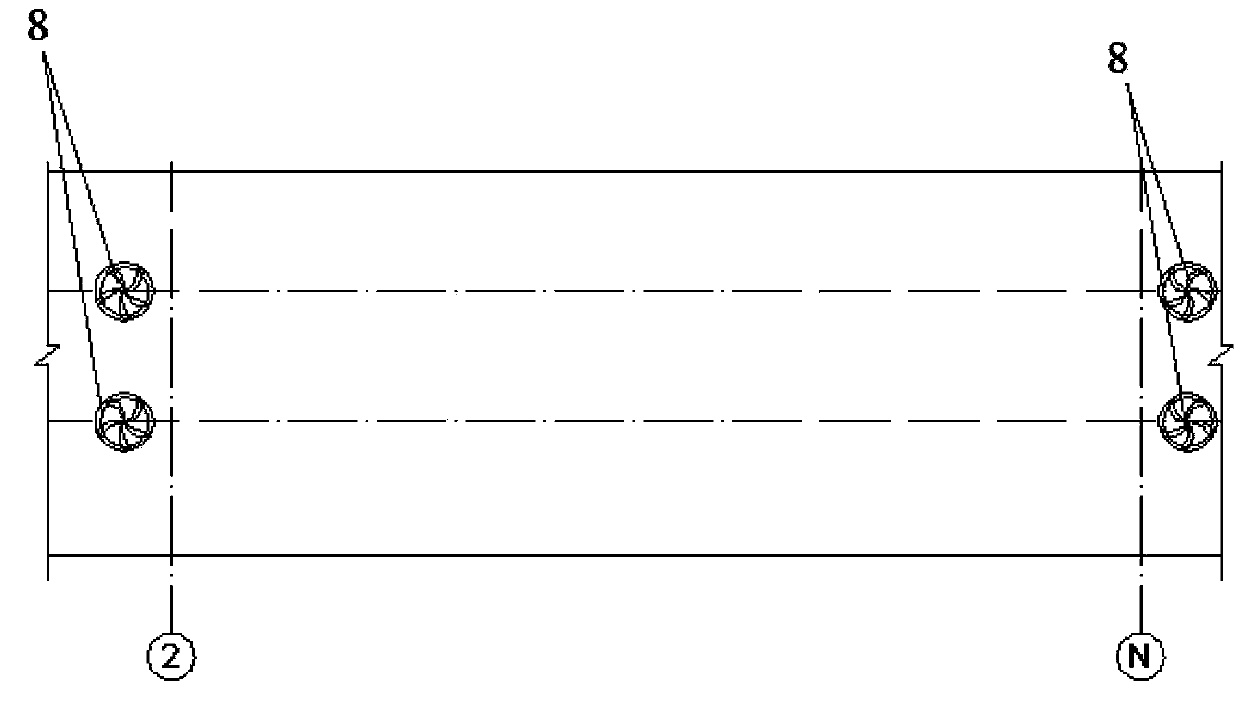

[0027] One end of the movable frame A and the fixed frame B are connected through the rotating bearing 7 located on the fixed frame B, and the other end of the movable frame A and the fixed frame B is connected through a transmission system composed of a gear motor 10, a transmission shaft 11, a gear 2 and a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com