Industrialized production method and filling device for spiced bar

A technology of filling equipment and a cross-cutting device, which is applied in the industrialized production of spiced sticks and the field of filling equipment, can solve the problems of insecure safety and quality, low processing efficiency, and high labor costs, and achieve simple, fast, and low-cost production methods , good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

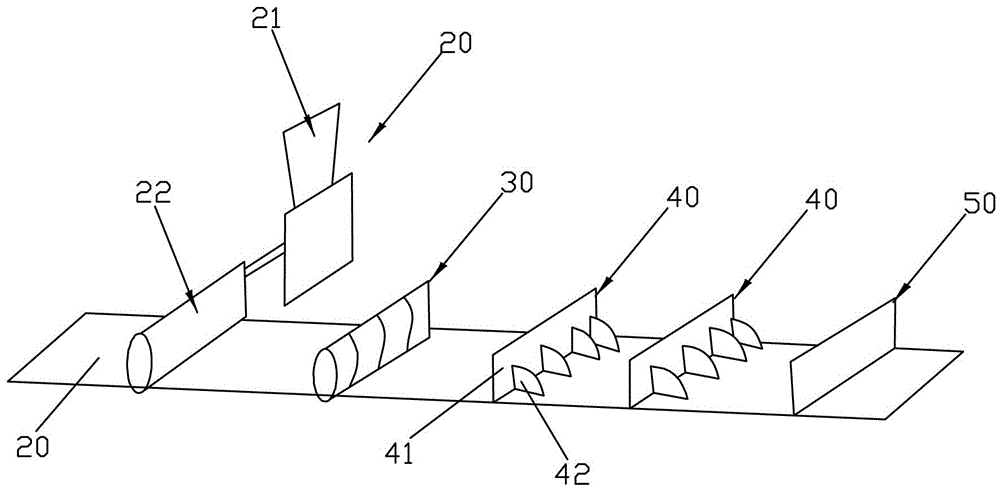

Image

Examples

Embodiment Construction

[0027] A method for industrialized production of spiced sticks, comprising:

[0028] Step 1, the step of preparing the raw meat, taking the frozen pork hind legs, thawing, washing, trimming the raw meat and then dicing to obtain diced meat, and marinating the diced meat; in this embodiment, the diced meat, carrots, water chestnuts and The mass ratio of the onion is 9-11:3.5-4.5:4.5-5.5:4.5-5.5; the diced meat is marinated for 11-13 hours; seasoning for marinating: 35-40 parts by weight of salt, 15-18 parts by weight of sugar The parts by weight are 12-16 parts by weight of five-spice powder, 5-8 parts by weight of chicken essence, and 300-600 parts by weight of sweet potato powder, which has good marinating effect and good taste.

[0029] Step 2, the step of preparing vegetables, the vegetables include carrots, water chestnuts and onions, screening, cleaning and cutting carrots, water chestnuts and onions, either shredded or diced;

[0030] Step 3, the rolling step, taking th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com