Sand supply amount control system for post-mixing type high-pressure jet cleaning, and method thereof

A high-pressure jet and post-mixing technology, which is applied in the direction of manufacturing tools, used abrasive processing devices, abrasives, etc., can solve problems such as no effective solutions, achieve effective control of cleaning effects, and prevent excessive mortar concentration or too low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

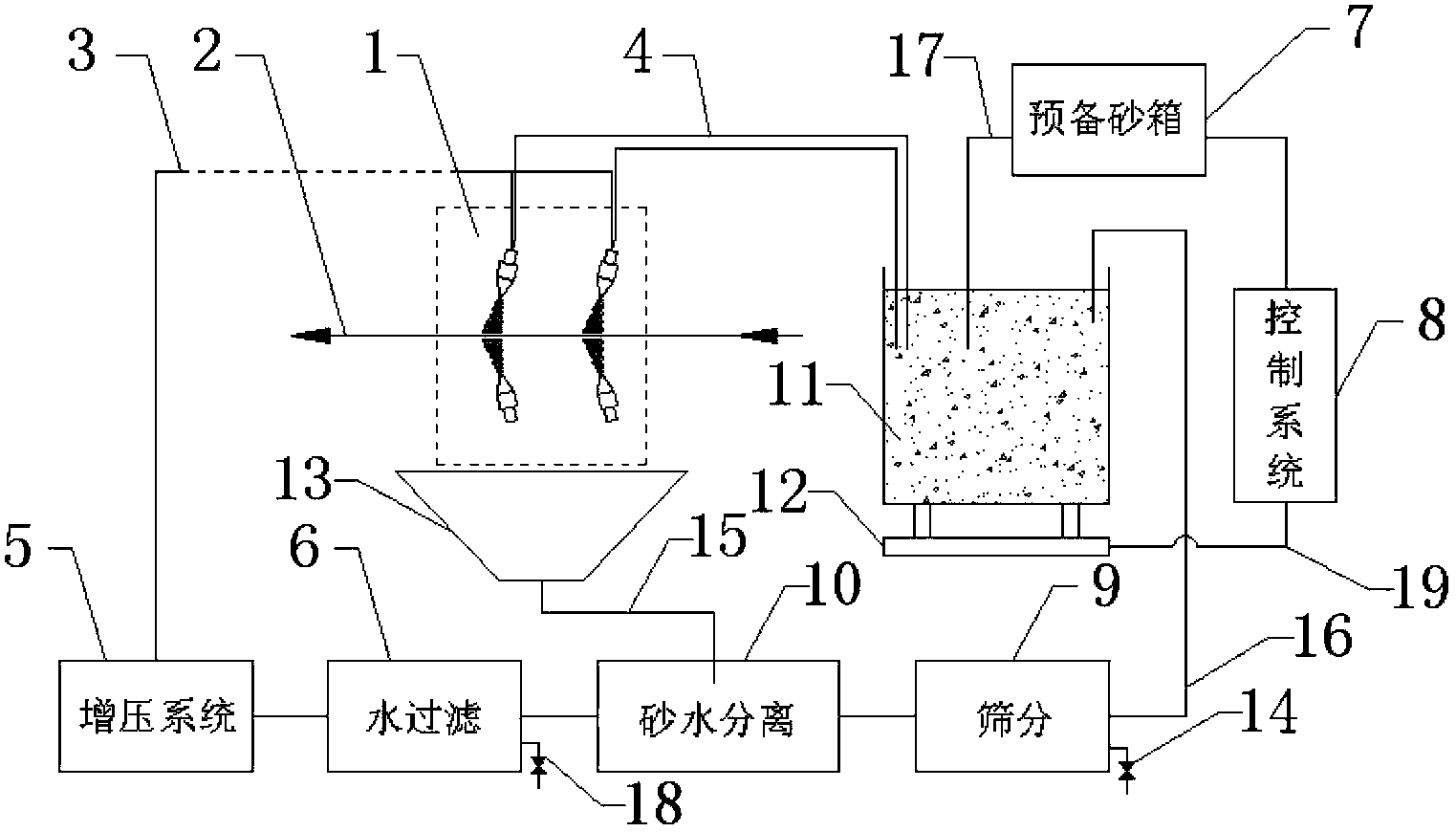

[0043] As mentioned above, specific embodiments of the present invention can be found in figure 1 Shown, in order to guarantee that the inventive method has desirable control effect, the embodiment of the present invention is as follows:

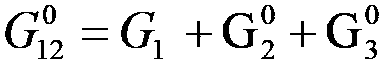

[0044] The medium parameters of the sand mixing tank 11 are as follows:

[0045] (1) The overall medium weight of the primary filling system is: 2000kg of abrasive grains and 20000kg of water medium;

[0046] (2) During stable operation, the abrasive grain in the sand supply mixing tank is 1000kg, and the water medium (water) is 500kg;

[0047] (3) The density of abrasive grains is 5×1000kg / m 3 , the density of water is 1000kg / m 3 ;

[0048] (4) The body weight of the sand supply mixing barrel is 1000kg;

[0049] (5) The effective volume of the sand supply mixing tank is 0.7m 3 , of which abrasive grain 0.2m 3 , water medium (water) 0.5m 3 ;

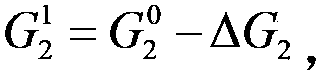

[0050] (6) The critical value affecting the output concentration of the sand supply mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com