Cold-rolled strengthened radiation-sintered composite steel plate and its manufacturing equipment

A composite steel plate and welding technology, applied in lamination devices, chemical instruments and methods, lamination, etc., can solve the problems of high manufacturing cost, waste of alloy plates, low cost performance, etc., and achieve the effect of small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

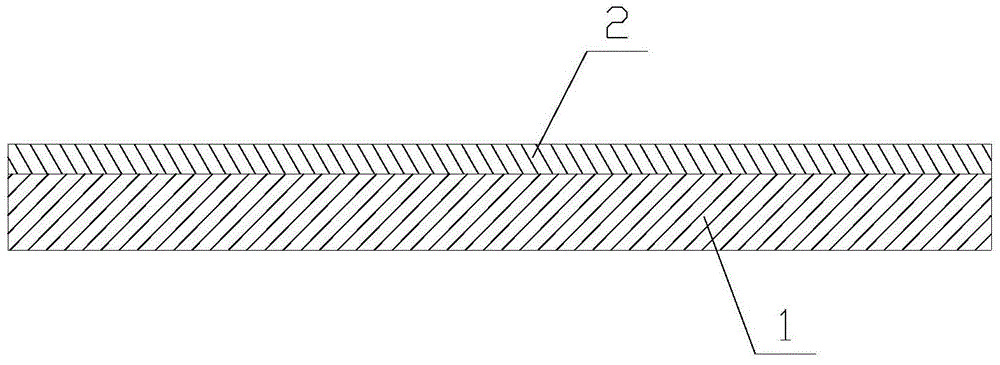

[0023] Cold-rolled strengthened radiation-sintered clad steel sheet, such as figure 1 , 4 As shown, it includes a substrate 1 and a panel 2. The substrate 1 is a steel plate, and the panel 2 is a metal sheet or an organic sheet. The panel 2 is located on one side of the substrate 1, and the panel 2 is connected to the surface of the substrate 1 by welding. Melting pressure means that the panel 2 in contact with the substrate 1 is radiated and melted by the radiation heating device 7, and then a high-intensity pressure is applied by the main roll 4, and the pressure load is more than 2,000 tons or 1.5-5.5 times the compressive strength of the substrate 1 , so that the panel 2 is connected to the substrate 1 by high-pressure pressure-attachment in a molten state, and the mechanical bonding under high pressure and the fusion bonding under high temperature are integrated to form an alloy transition layer between the substrate 1 and the panel 2, which greatly improves the composite...

Embodiment 2

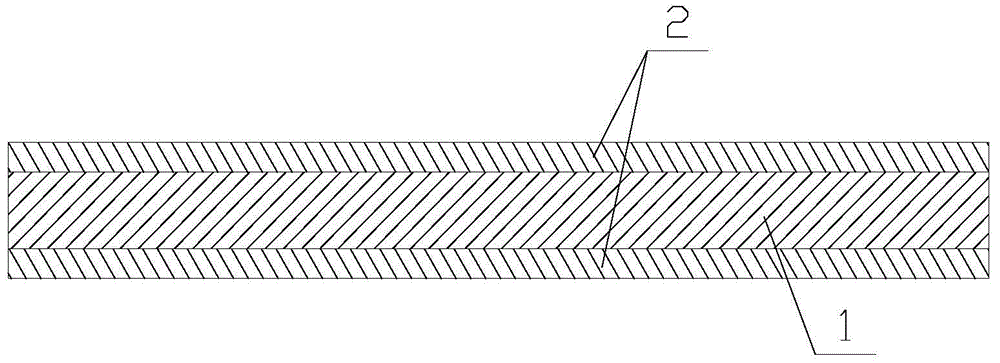

[0033] Cold-rolled strengthened radiation-sintered clad steel sheet, such as figure 2 , 4 As shown, it includes a substrate 1 and a panel 2. The substrate 1 is a steel plate, and the panel 2 is a metal sheet or an organic sheet.

[0034] The roughness of the bonding surface of the substrate 1 and the panel 2 is 200 μm. The joint surface of substrate 1 and panel 2 is a clean surface, which needs to be derusted, dewatered, degreased, and ash-removed.

[0035] The anchor grain direction of the roughness of the panel 2 is consistent with the anchor grain direction of the roughness of the substrate 1 . The roughness can be shot blasting, and high-strength steel wire roller can be used for high-speed padding, which has directionality. In this plan, fine shot blasting is used first, and then the steel wire wheel is used to scratch the anchor pattern to form a metallurgical bond. Panel 2 is an aluminum plate.

[0036] The manufacturing equipment for cold-rolled strengthened radia...

Embodiment 3

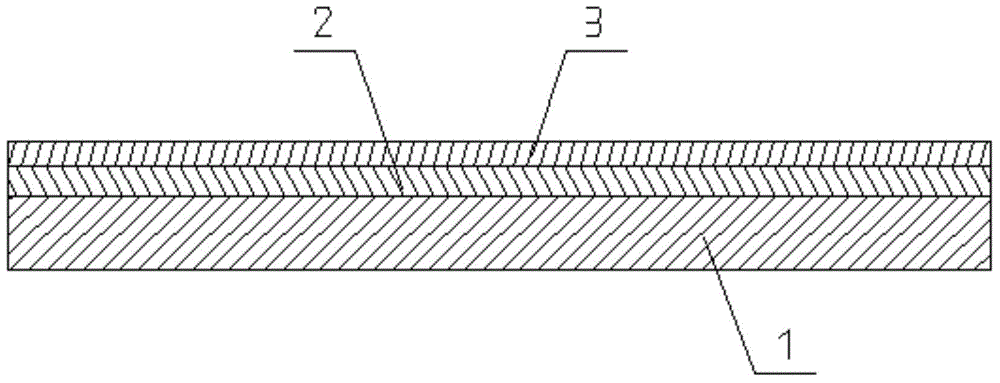

[0042] Cold-rolled strengthened radiation-sintered clad steel sheet, such as image 3 , 4 As shown, it includes a substrate 1 and a panel 2. The substrate 1 is a steel plate, and the panel 2 is a metal sheet or an organic sheet. The panel 2 is located on one side of the substrate 1, and the panel 2 is connected to the surface of the substrate 1 by welding. A hard plastic or soft metal liner 3 is arranged between the base plate 1 and the panel 2, and the soft metal liner 3 is soft metal such as zinc plate or copper plate, which is applicable when the surface of the base plate 1 is uneven.

[0043] The roughness of the bonding surface of the substrate 1 and the panel 2 is 300 μm. The joint surface of substrate 1 and panel 2 is a clean surface, which needs to be derusted, dewatered, degreased, and ash-removed.

[0044] The anchor grain direction of the roughness of the panel 2 is consistent with the anchor grain direction of the roughness of the substrate 1 . The roughness can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com