Single-chain-type conveyer

A conveyor and single-chain technology, applied in the field of single-chain conveyors, can solve the problems of harsh environment adaptability, poor transmission stability, inconvenient adjustment and maintenance, etc., and achieve the effect of enhancing conveying performance and safety factor, and moving smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

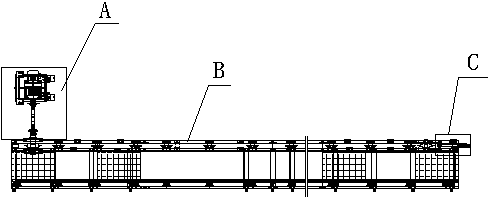

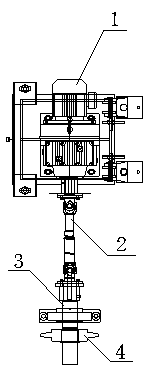

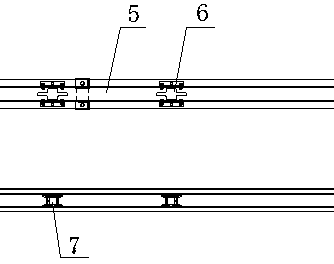

[0014] The specific embodiment of the present invention is described below in conjunction with accompanying drawing: a kind of single-chain conveyer as shown in the figure, comprises frame, and drive system A, transmission system B and tensioning system C are arranged at least sequentially on frame, machine One side of the frame is provided with a drive system, the drive system includes a motor 1 and a drive shaft 2, the motor is arranged on the side of the frame where the drive system is located, one end of the drive shaft 2 is connected to the main shaft of the motor 1, and the other end is connected to the sprocket shaft 3 , the other end of the sprocket shaft is provided with a power sprocket 4, and the chain is sleeved on the power sprocket; the transmission system includes a delivery track 5, a skid and a chain, and one side of the delivery track is provided with a plurality of transmission sprockets 6, and the other There are multiple rollers 7 on one side, one side of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap