Automatic stacking system and operation control process

A palletizing system and automatic technology, applied in the operation control process of the automatic palletizing system, in the field of the automatic palletizing system, can solve the problems such as can not meet the requirements of the use of the turnover box, large floor space, high price, etc., and achieve easy follow-up maintenance. , low energy consumption, convenient and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

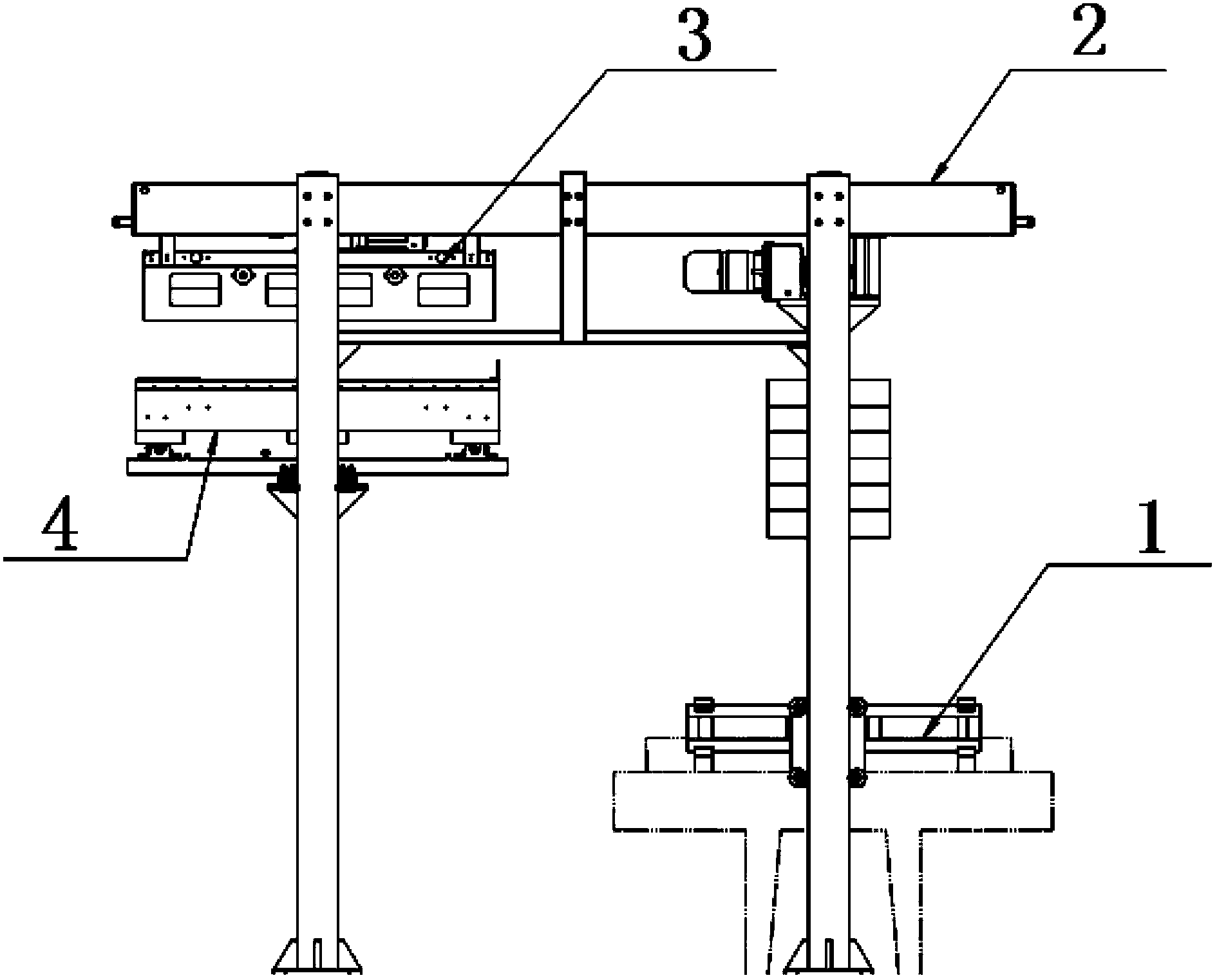

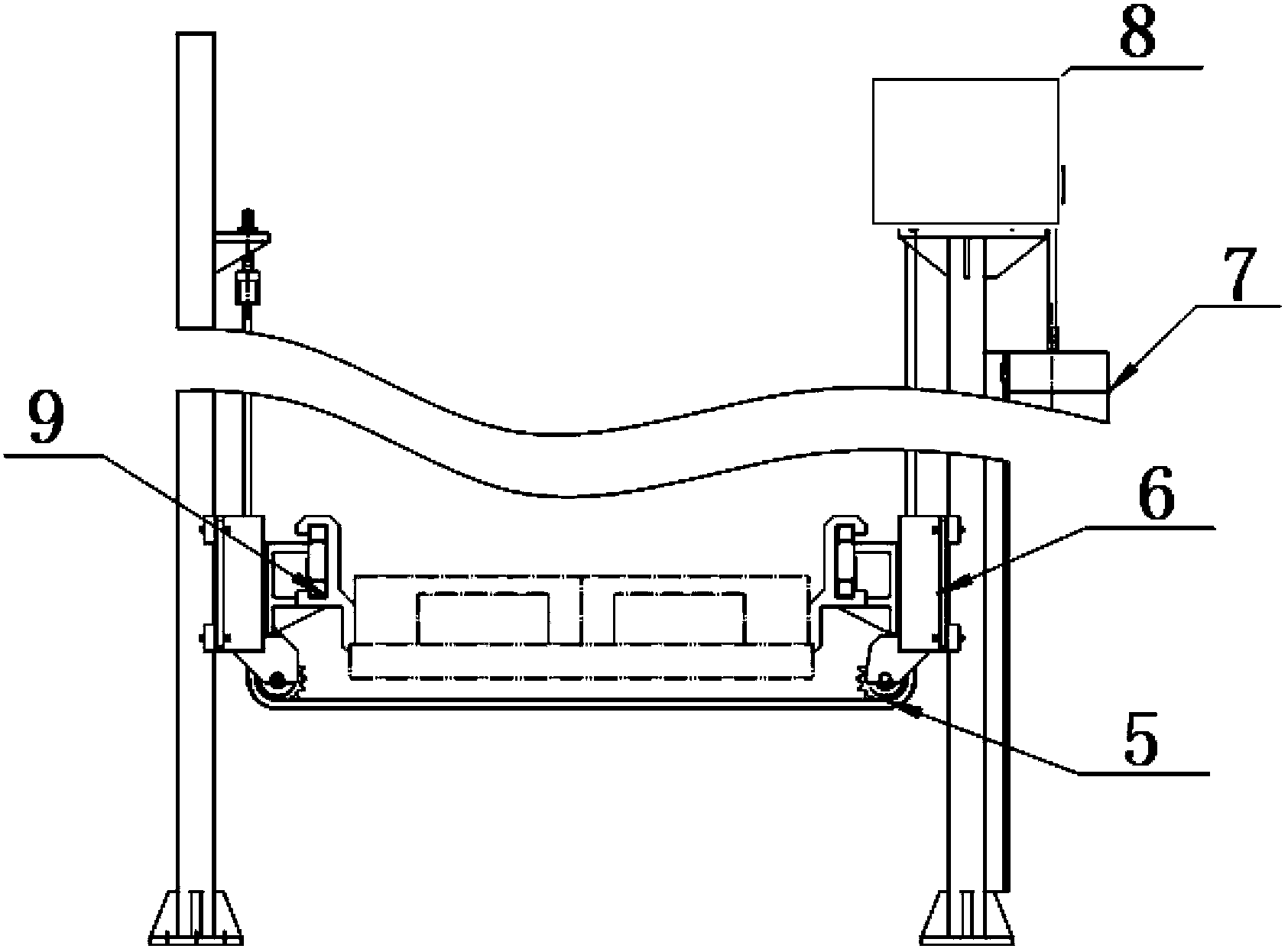

[0041] see Figure 1-4 , an automatic palletizing system of the present invention is composed of a pallet lifting mechanism 1, a bracket 2, a running trolley 3, and a buffer mechanism 4. The pallet lifting mechanism is installed on the front column of the bracket, and the tray lifting mechanism can move up and down along the front column Sliding, the buffer mechanism is installed on the rear column of the support, the buffer mechanism can slide up and down along the rear column, the running trolley is installed on the beam of the bracket, and the running trolley can slide back and forth along the beam.

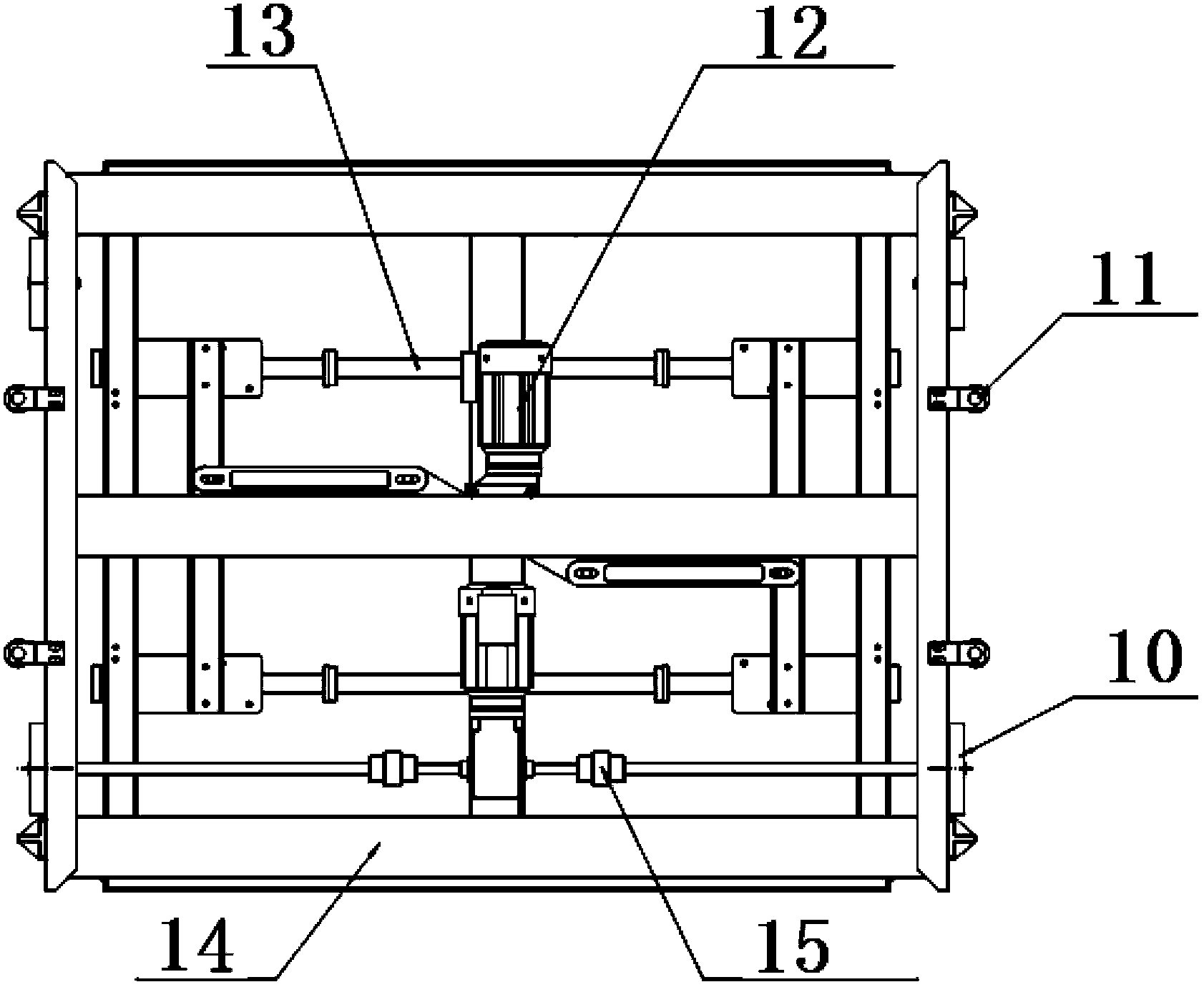

[0042] The pallet lifting mechanism is composed of a lifting motor, a pallet fork, a counterweight, a guiding mechanism, and a transmission mechanism. The guiding mechanism is connected with the pallet fork and installed on the column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com