Swinging-arm-type flexible belt bundle winding machine

A technology of flexible belt and winding machine, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., which can solve the problems of high drive motor power, high power consumption of equipment, and low space utilization, and reduce power consumption. consumption, precise control, and solve the effect of low equipment space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

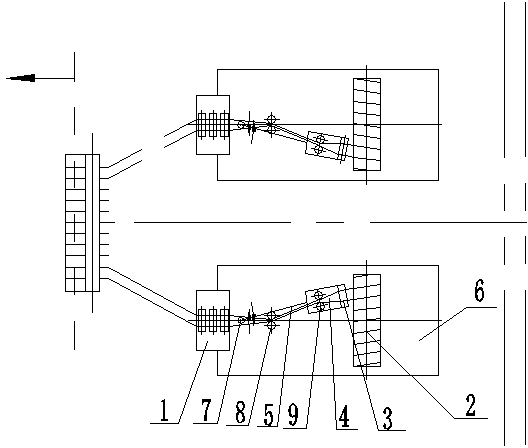

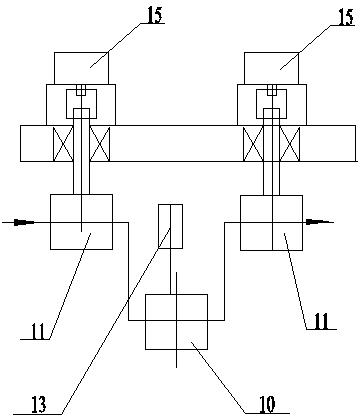

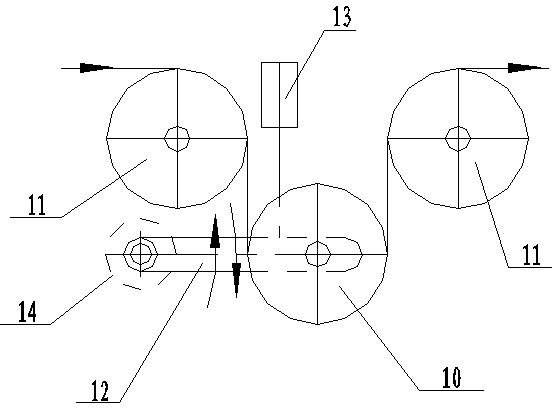

[0047] Use the fabric making machine or unwinding machine to first release the flexible tape material to a certain length, and the starting end of the released flexible tape material passes through the functional pulley block 1, the first tape section torsion pulley block 8, the second tape section torsion pulley block 9 and Tape export pulley 3, the starting end of the flexible strip passes through the strip export pulley 3 and then is wound on the inflatable shaft assembly 2 with adhesive tape, the strip exit pulley 3 and the second strip section torsion pulley block 9 are arranged on the export pulley mounting plate 4 Above, the lead-out pulley installation plate 4 is arranged on one end of the lead-out pulley swing arm 5, and the other end of the lead-out pulley swing arm 5 is connected with the swing arm shaft 7. The expansion shaft assembly 2 is arranged on the main body 6 of the winding machine. After starting the winding machine to complete the winding preparation work,...

Embodiment 2

[0051] Use the fabric making machine or unwinding machine to first release the flexible tape material to a certain length, and the starting end of the released flexible tape material passes through the functional pulley block 1, the first tape section torsion pulley block 8, the second tape section torsion pulley block 9 and Tape export pulley 3, the starting end of the flexible strip passes through the strip export pulley 3 and then is wound on the inflatable shaft assembly 2 with adhesive tape, the strip exit pulley 3 and the second strip section torsion pulley block 9 are arranged on the export pulley mounting plate 4 Above, the lead-out pulley installation plate 4 is arranged on one end of the lead-out pulley swing arm 5, and the other end of the lead-out pulley swing arm 5 is connected with the swing arm shaft 7. The expansion shaft assembly 2 is arranged on the main body 6 of the winding machine. After starting the winding machine to complete the winding preparation work,...

Embodiment 3

[0055] Use the fabric making machine or unwinding machine to first release the flexible tape material to a certain length, and the starting end of the released flexible tape material passes through the functional pulley block 1, the first tape section torsion pulley block 8, the second tape section torsion pulley block 9 and Tape export pulley 3, the starting end of the flexible strip passes through the strip export pulley 3 and then is wound on the inflatable shaft assembly 2 with adhesive tape, the strip exit pulley 3 and the second strip section torsion pulley block 9 are arranged on the export pulley mounting plate 4 Above, the lead-out pulley installation plate 4 is arranged on one end of the lead-out pulley swing arm 5, and the other end of the lead-out pulley swing arm 5 is connected with the swing arm shaft 7. The expansion shaft assembly 2 is arranged on the main body 6 of the winding machine. After starting the winding machine to complete the winding preparation work,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com