Rice husk thermal insulation porous block and preparation method thereof

A technology of porous block and rice husk, which is applied in the field of building wall materials, can solve the problems such as the thermal conductivity and pressure strength of the wall are not easy to reach the standard, the amount of rice husk is limited, etc., and achieves good freeze-thaw and shrinkage performance. Convenient construction and transportation, strong bite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

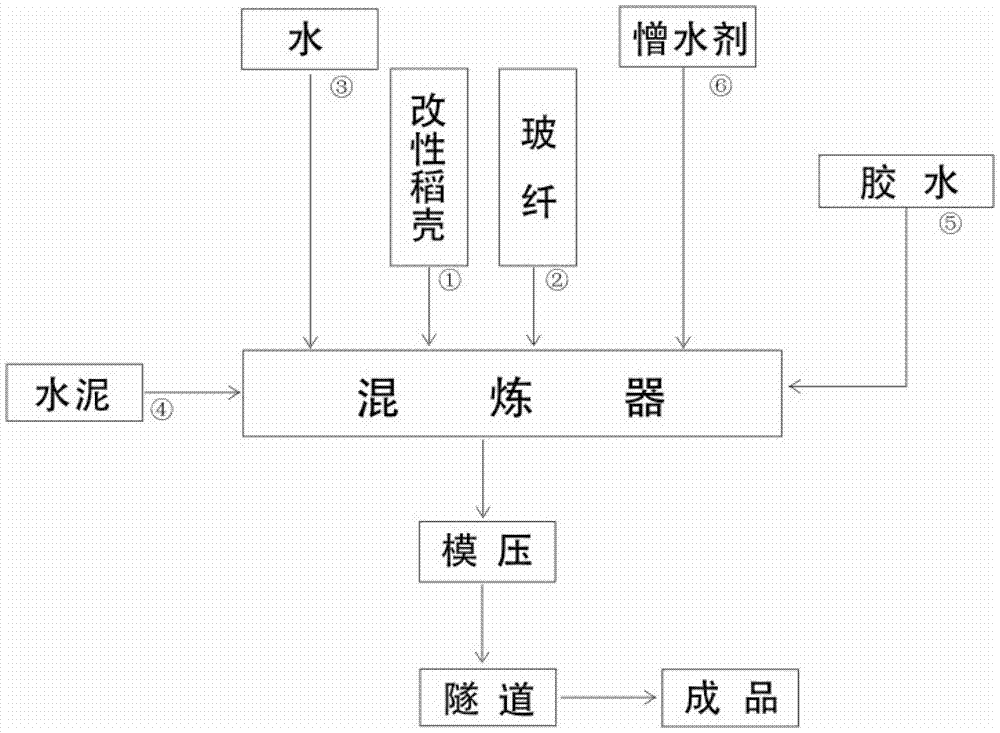

Method used

Image

Examples

Embodiment 1

[0017] The density of the modified rice husk is 115-125g / L, and the preferred density in this case is 120g / L.

[0018] Original rice husk / modified rice husk=0.79

[0019] The length of the short glass fiber is 20-30 mm.

[0020] The amount of modified rice husk added to the wall block is set: 2.2L / kg cement (1kg of cement is mixed with 2.2L of rice husk)

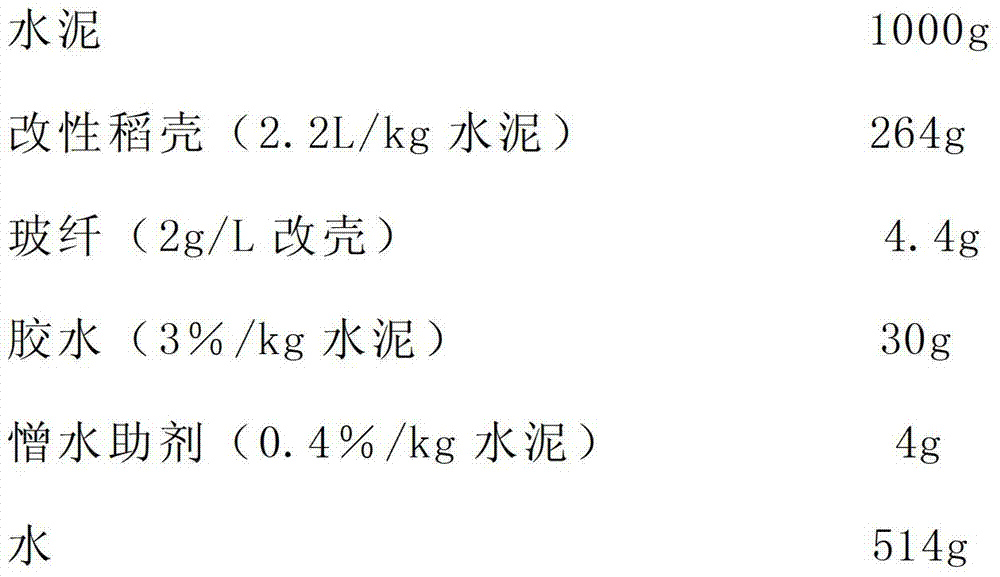

[0021] Setting of basic formula of rice husk insulation porous block:

[0022]

[0023] Taking 1000g of cement as an example, the formula for calculating the weight of water is as follows:

[0024] 1000g (cement)×0.17=170g

[0025] 2.2L (modified rice husk)×0.17×1000g / L (water density)-30g (glue quality)=344g

[0026] The weight of water=170g+344g=514g

[0027] Among them, 0.17 is a constant, which is convenient for calculating the amount of water added when the cement and modified rice husk in the balance formula change, and is suitable for the environment where the molding pressure is 5MPa. When the molding pressu...

Embodiment 2

[0029] Setting of basic formula of rice husk insulation porous block:

[0030] Others are the same as in Embodiment 1, and the changes are as follows:

[0031]

[0032]

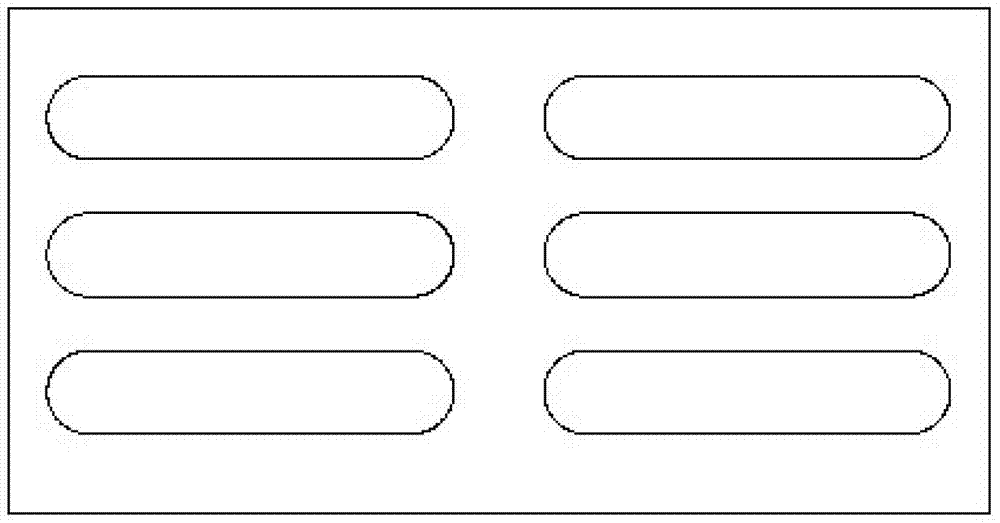

[0033] like figure 2 As shown, the rice husk heat-insulating porous block prepared by the above-mentioned preparation method of the rice husk heat-insulating porous block includes a brick body, which is provided with a number of through holes, and the porosity is 40%, and the density is 0.7kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com