Method for producing ethanol by hydrogenation of syngas

A technology for producing ethanol and synthesis gas, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problem of low ethanol selectivity and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

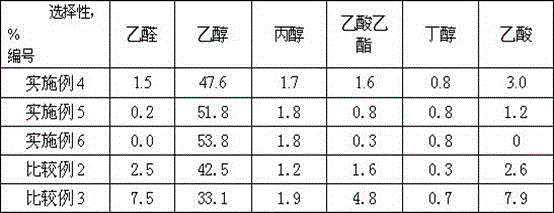

Examples

Embodiment 1

[0019] Dissolve 8 grams of copper nitrate (containing 3 crystal waters) and 28.88 grams of zinc nitrate (containing 6 crystal waters) in 160 ml of absolute ethanol; dissolve 14 grams of oxalic acid in 80 ml of absolute ethanol, the two ethanol The solution was mixed and precipitated under rapid stirring, continued stirring for 2 hours, suction filtered, and the filter cake was dried at room temperature for 2 hours, then baked in an oven at 110°C for 15 hours, and roasted at 400°C for 5 hours to obtain CuO (25%)-ZnO (75% ) Catalyst, tablet molding, take 20-40 mesh for use, number JQ-1.

Embodiment 2

[0021] Dissolve 15 grams of copper nitrate (containing 3 crystal waters), 17.95 grams of zinc nitrate (containing 6 crystal waters), and 2.5 grams of cobalt nitrate (containing 6 crystal waters) in 155 ml of absolute ethanol; 14.16 grams of oxalic acid Dissolve in 81 ml of absolute ethanol, the two ethanol solutions are mixed and precipitated under rapid stirring, continue to stir for 2 hours, filter with suction, dry the filter cake at room temperature for 2 hours, put it in an oven for 15 hours at 110°C, and roast at 400°C for 4 hours , to obtain Cu(47.0%)-Zn(47.0%)-Co(6%) catalyst, press into tablets, take 20-40 meshes for use, code JQ-2.

Embodiment 3

[0023] Dissolve 15 grams of copper nitrate (containing 3 crystal waters), 5.99 grams of zinc nitrate (containing 6 crystal waters), 1.5 grams of ferric nitrate (containing 9 crystal waters), and 1 gram of chromium nitrate (containing 9 crystal waters) in 103 ml of absolute ethanol; 9.56 g of oxalic acid was dissolved in 55 ml of absolute ethanol, the two ethanol solutions were mixed and precipitated under rapid stirring, continued stirring for 2 hours, suction filtered, and the filter cake was dried at room temperature for 2 hours and then placed in an oven. Bake at 110°C for 15 hours, then bake at 400°C for 4 hours to obtain Cu(70.5%)-Zn(23.5%)-Fe(3.7%)-Cr(2.3%) catalyst, press into tablets, take 20-40 meshes for use , No. JQ-3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap