A thermally bonded non-woven fabric and its production method and use

A production method and technology of non-woven fabrics, applied in the direction of separation methods, textiles and papermaking, chemical instruments and methods, etc., can solve the problems of easy crushing of fibers, small amount of dust collection, low strength of non-woven fabrics, etc., and achieve high strength , High dust collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

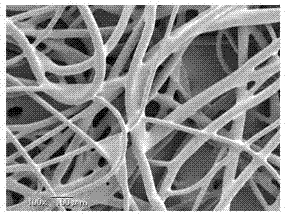

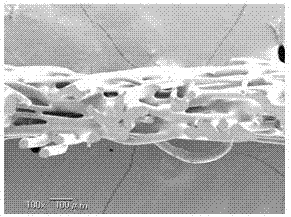

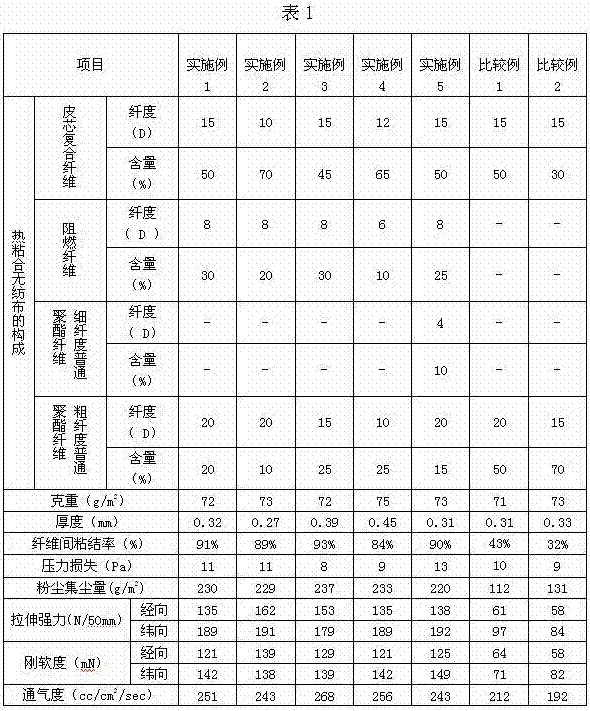

[0041] 50% by weight of skin-core composite fibers, 30% by weight of flame-retardant fibers, and 20% by weight of 20 denier ordinary polyester fibers are fed, and after opening, carding, and cross-lapping, a composite fiber web layer is formed. Pass the composite fiber web layer above at a speed of 10 m / min through a hot air box at a temperature of 200°C for preliminary thermal bonding, and then pass through a mesh belt with 12 pairs of hot rollers at a speed of 10 m / min at a temperature of 150°C above and below. The hot pressing device is used for heat setting and reinforcement, and the pressure at the entrance of the mesh belt hot pressing device (for non-woven fabrics) is 0kg / cm 2 , the pressure at the outlet is 50 kg / cm 2 . At the same time, the spacing at the entrance of the mesh belt is 40mm, and the spacing at the exit is 0.05mm. After being bonded by cold pressing rolls, the thermally bonded nonwoven fabric of the present invention is finally obtained. Observing the...

Embodiment 2

[0043] 70% by weight of skin-core composite fibers, 20% by weight of flame-retardant fibers, and 10% by weight of ordinary polyester fibers with a denier thickness of 20 denier are fed, and after opening, carding, and cross-lapping, a composite fiber web layer is formed. Pass the above composite fiber web layer through a hot air box with a temperature of 200°C at a speed of 8 m / min for preliminary thermal bonding, and then pass through a mesh belt with 8 pairs of hot rollers above and below 160°C at a speed of 8 m / min. The hot pressing device is used for heat setting and reinforcement, and the pressure at the entrance of the mesh belt hot pressing device (for non-woven fabrics) is 0kg / cm 2 , the pressure at the outlet is 40 kg / cm 2 . At the same time, the spacing at the entrance of the mesh belt is 45mm, and the spacing at the exit is 0.08mm. After being bonded by cold pressing rolls, the thermally bonded nonwoven fabric of the present invention is finally obtained. Observi...

Embodiment 3

[0045] 45% by weight of skin-core composite fibers, 30% by weight of flame-retardant fibers, and 25% by weight of ordinary polyester fibers with a denier thickness of 15 denier are fed, and a composite fiber web layer is formed after opening, carding, and cross-lapping. Preliminary thermal bonding of the above-mentioned composite fiber web layer through a hot air box with a temperature of 250°C at a speed of 15 m / min, and then through a circulation oven at a speed of 15 m / min with 4 pairs of symmetrical hot rollers at 200°C. Heat setting reinforcement, the pressure at the entrance of the hot roller (for non-woven fabrics) is 0kg / cm 2 , the pressure at the outlet is 60 kg / cm 2 . At the same time, the pitch at the entrance of the heat roller is 45 mm, and the pitch at the exit is 0.06 mm. After being bonded by cold pressing rolls, the thermally bonded nonwoven fabric of the present invention is finally obtained. Observing the cross-section of the above-mentioned nonwoven fabr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com