Splicing trussed type pile leg device

A truss-type, pile-leg technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the difficult problems of deep-water platform operations, platform towing safety issues, platform relocation safety threats, length of pile legs and Large quality and other issues, to achieve the effect of simple structure, high safety, and increase the depth of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

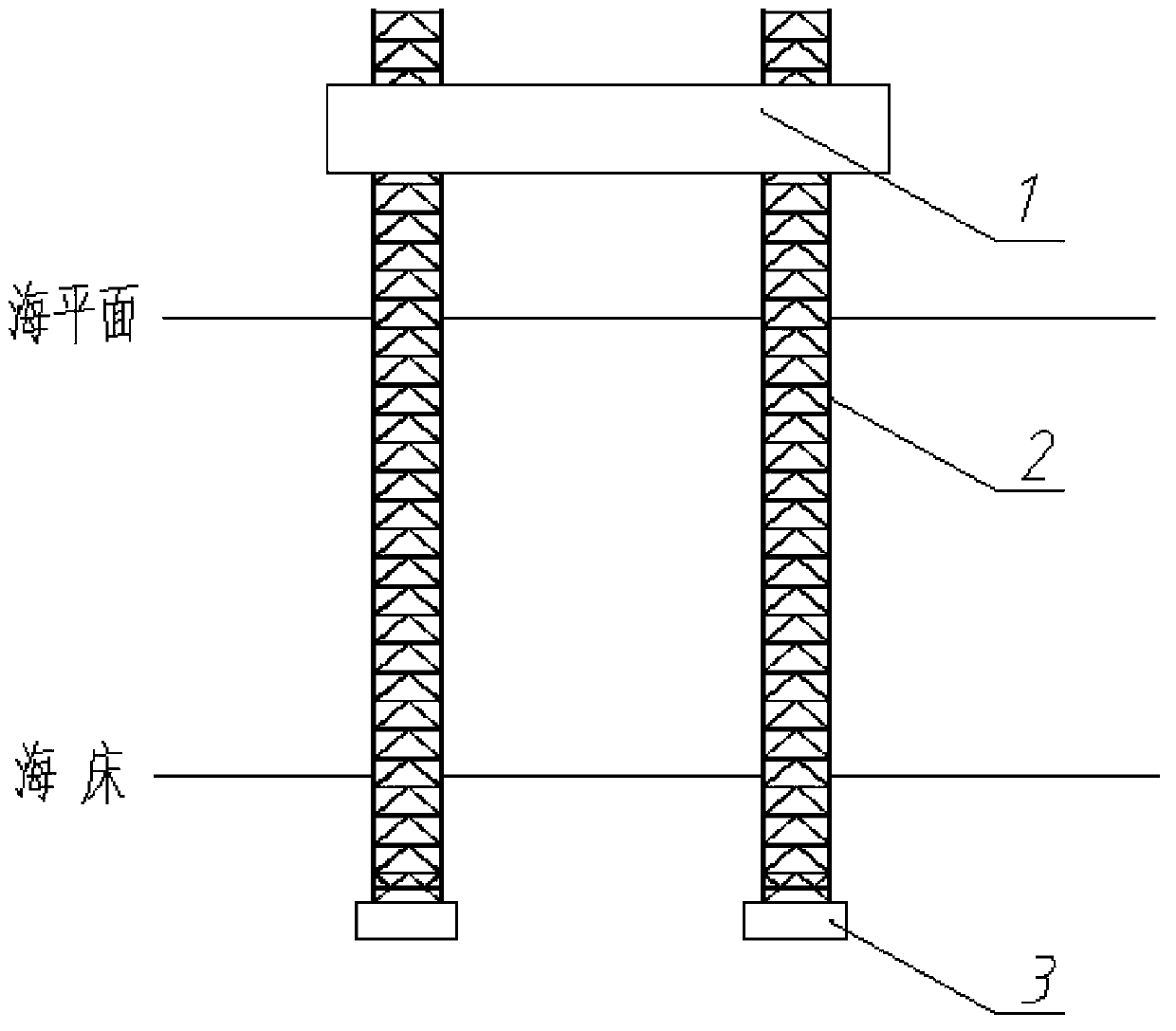

[0028] Such as figure 1 Shown is the normal operating attitude of the jack-up offshore platform. The platform 1 is mechanically connected with the leg assembly 2 and fixed at a certain working height on the sea level; the spud shoe 3 is welded to the lower end of the leg 2 to prop up the platform 1 .

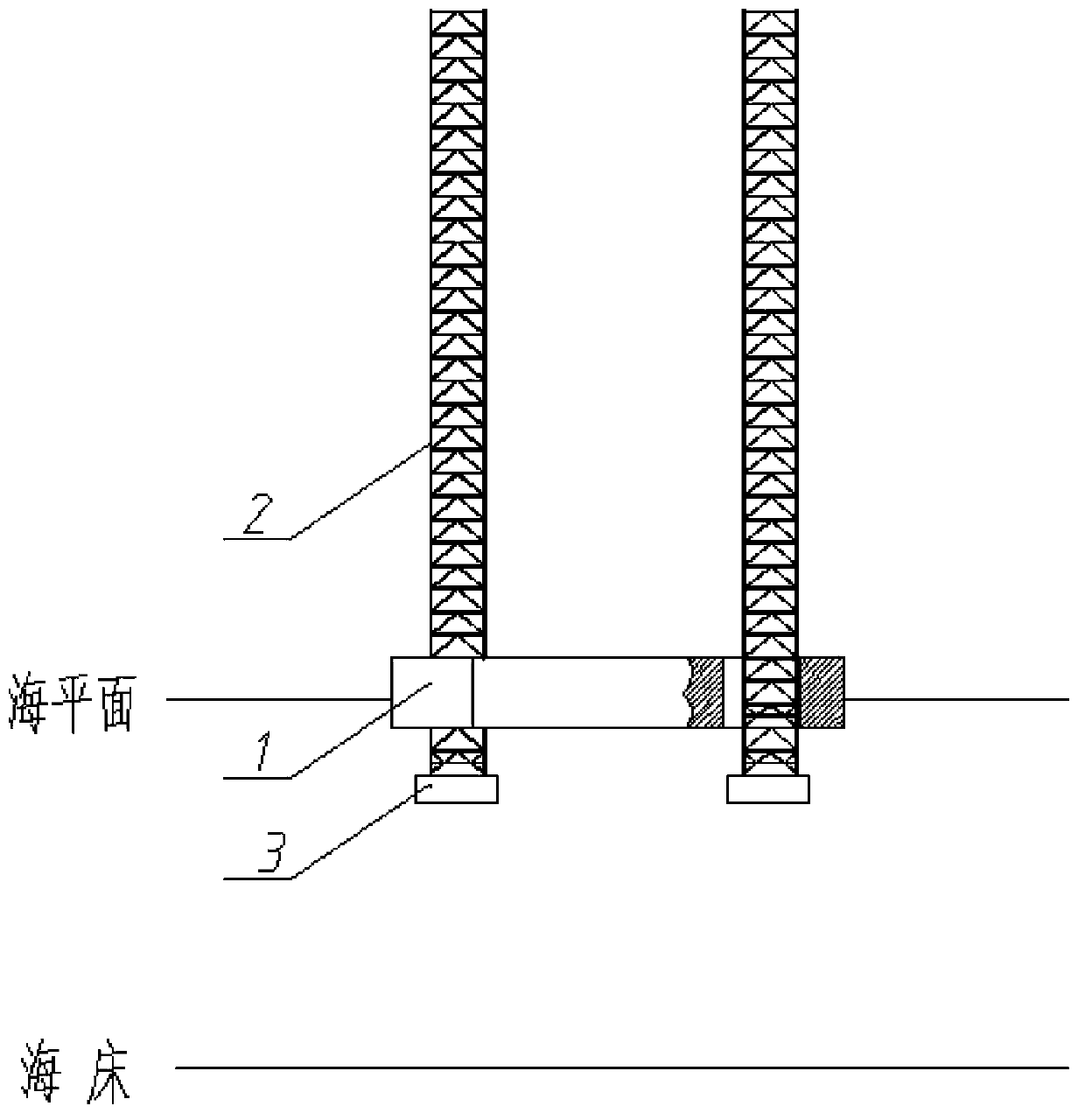

[0029] Such as figure 2 Shown is the towing attitude of the jack-up offshore platform. The platform 1 floats on the sea level; most of the leg assembly 2 is raised above the platform 1 .

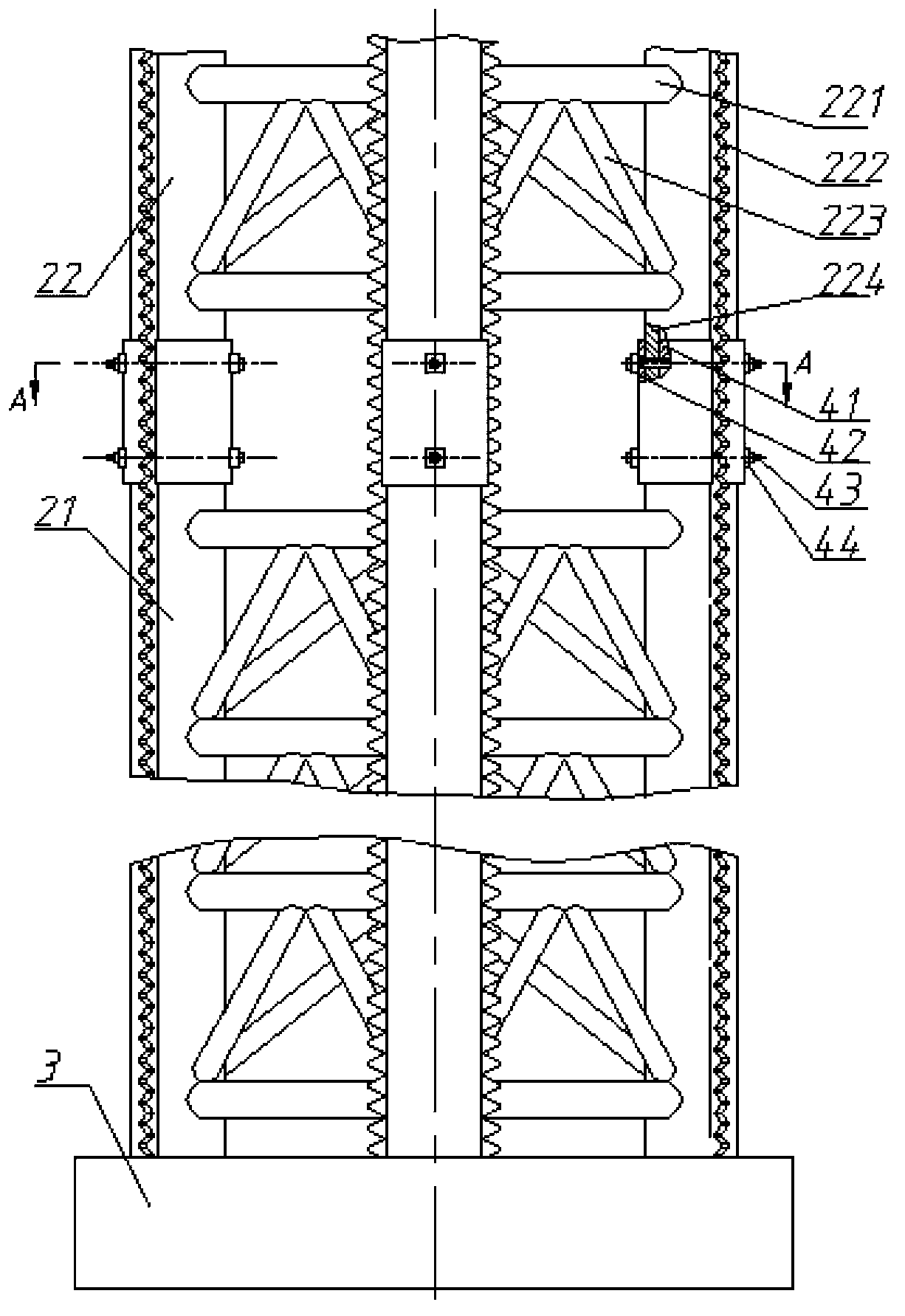

[0030] Such as image 3 As shown, an assembled truss-type leg device of the present invention includes a truss-type leg 22, and the truss-type leg 22 includes chords 224 distributed in an equilateral triangle by three vertical sections, and each chord One tooth rack 222 is symmetrically connected to the outer peripheral surface of the rod 224 in the axial direction, and at least two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com