Fiber-reinforced plastic sheet pile

A technology for strengthening plastics and fibers, which can be used in sheet pile walls, chemical instruments and methods, infrastructure engineering, etc., and can solve problems such as inability to cut sheet piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

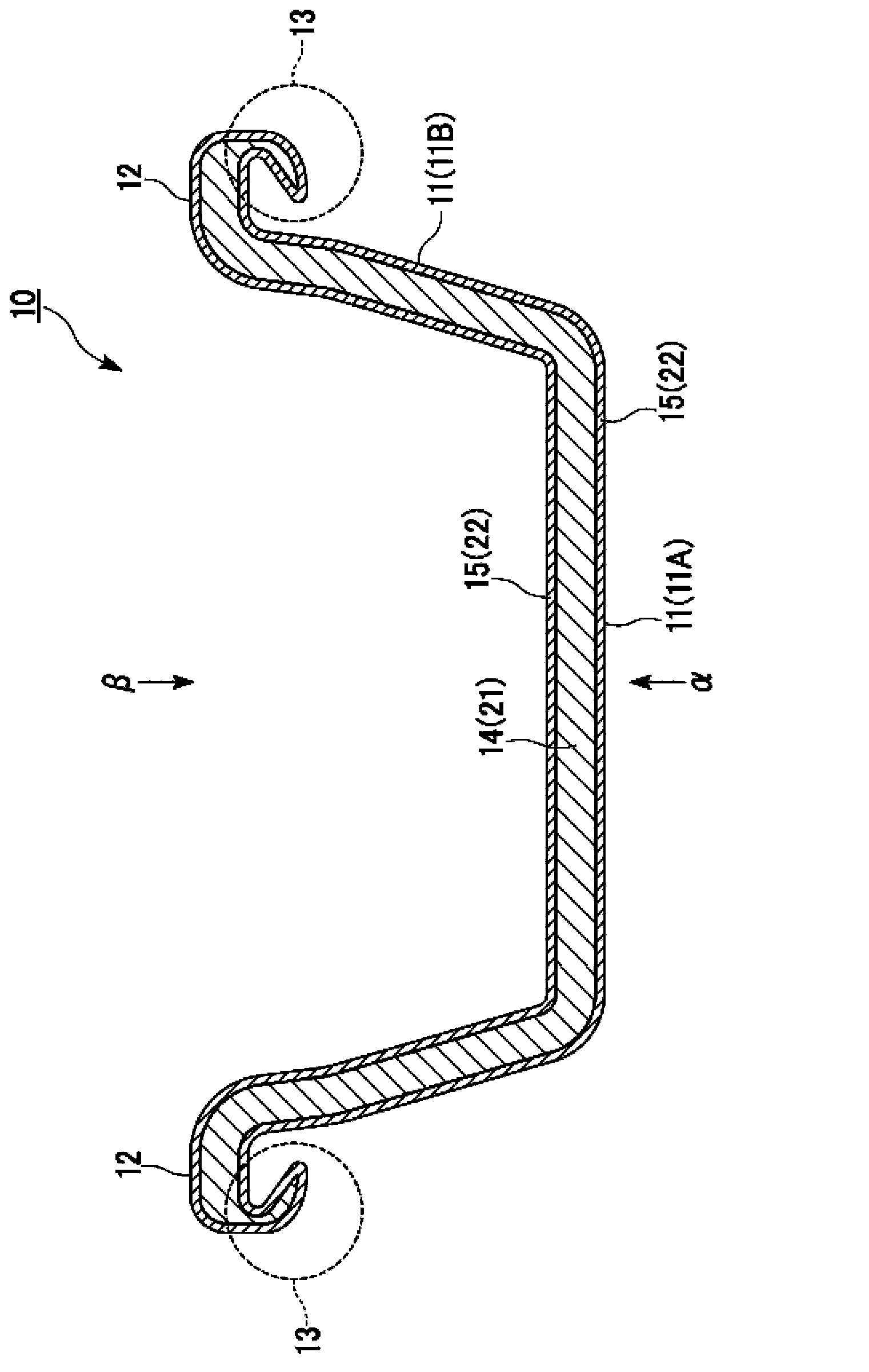

Embodiment 1

[0080] Prepare #300 glass fiber short glass mat (trade name: MC300A, manufactured by Nitto Boseki Co., Ltd.), #800 glass fiber roving cloth (trade name: WR800C-100, manufactured by Nitto Boseki Co., Ltd.), #330 Carbon fiber cloth (trade name: W-6101, flat-woven carbon fiber cloth, manufactured by TOHO TENAX Co., Ltd.), #300 carbon fiber unidirectional cloth (trade name: UM46-30G, manufactured by Toray Industries Inc.). Here, each fiber is rectangular, and the width of each fiber used is described in Table 1. The size of the fibers was determined so that they could be placed in the preforming mold under the conditions listed in Table 1. As a preforming die, a steel sheet pile type III die having a length of 6000 mm was prepared.

[0081] These carbon fibers and glass fibers were stacked one by one in the preforming mold to obtain the fiber constitution shown in Table 1. As a result, a fiber preform having approximately the same shape as the final molded product (FRP sheet pil...

Embodiment 2

[0104] Make carbon fiber and glass fiber into the fiber structure shown in Table 2, such as disposing #300 carbon fiber unidirectional fabric (UD) on the side part (11B) of the 36th to 37th layer, or adopting a 45-layer structure, etc. The same operation was performed in Example 1 to obtain the FRP sheet pile of Example 2.

[0105] Table 2

[0106]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap