Pipe joint

A technology for pipe joints and root canals, applied in the field of pipe joints, can solve problems such as difficult fastening operations, increased construction costs, and high flange prices, and achieves the effects of easy construction, improved constructability, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

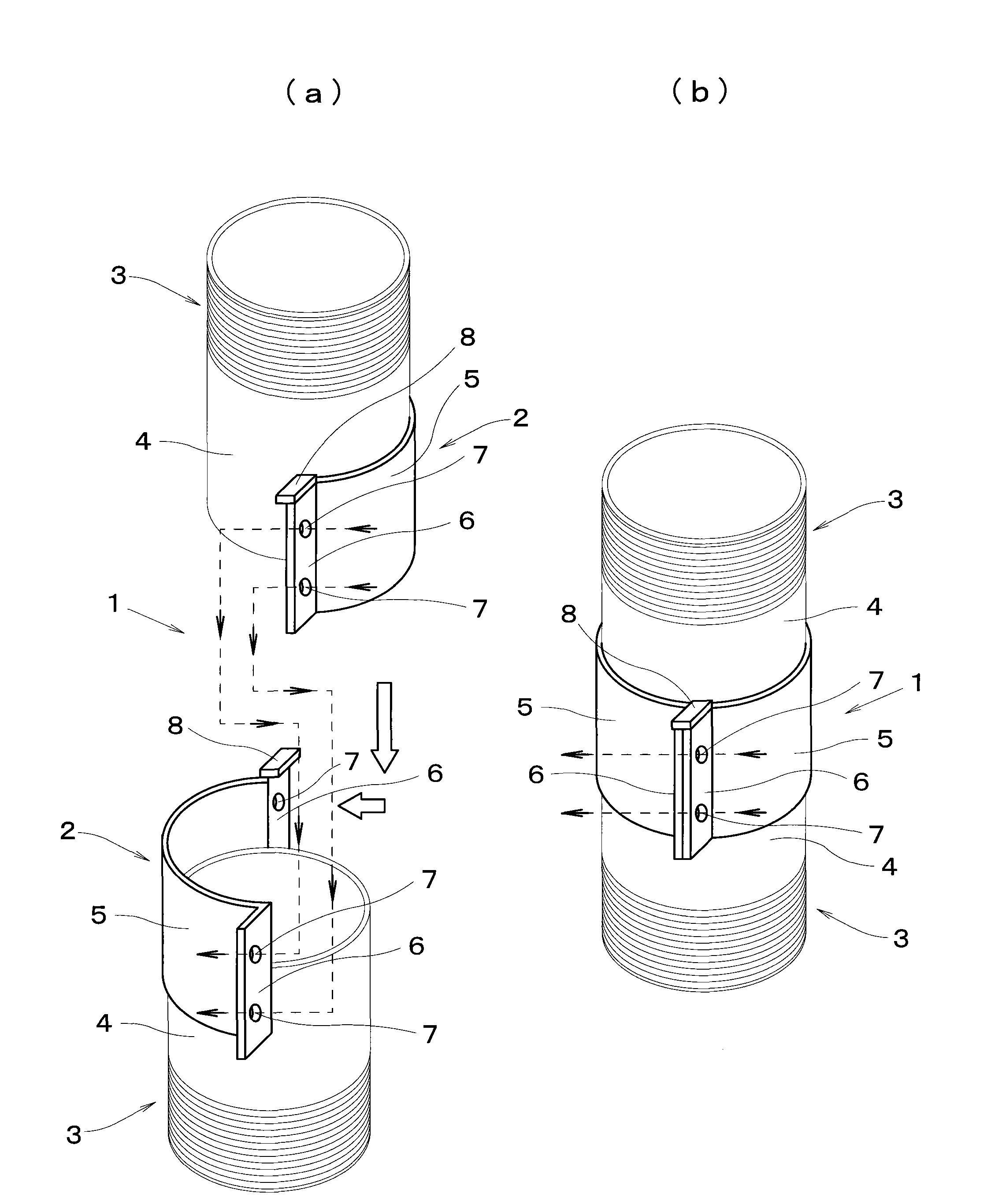

[0042] Preferred embodiments of the present invention will be described below with reference to the drawings.

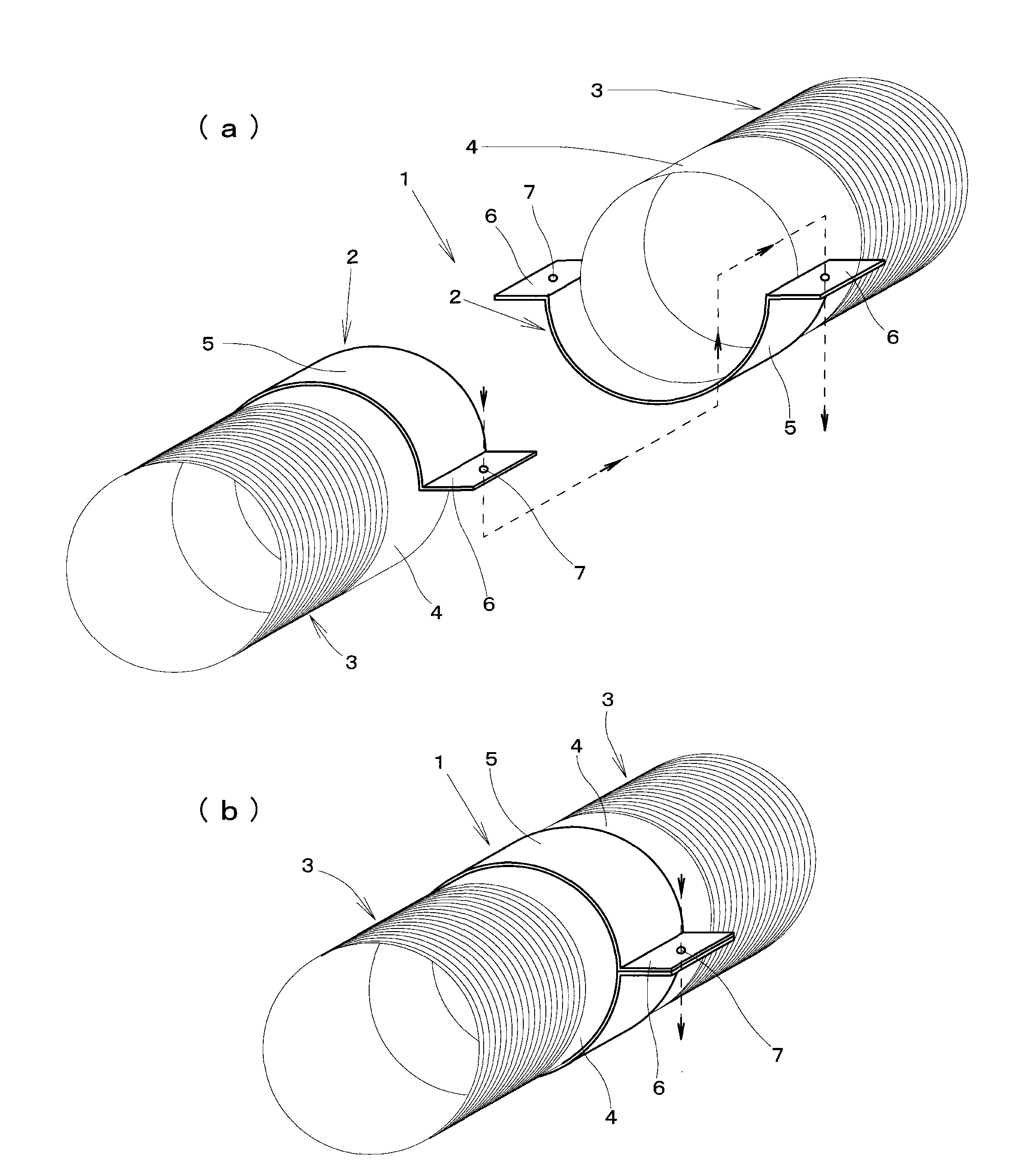

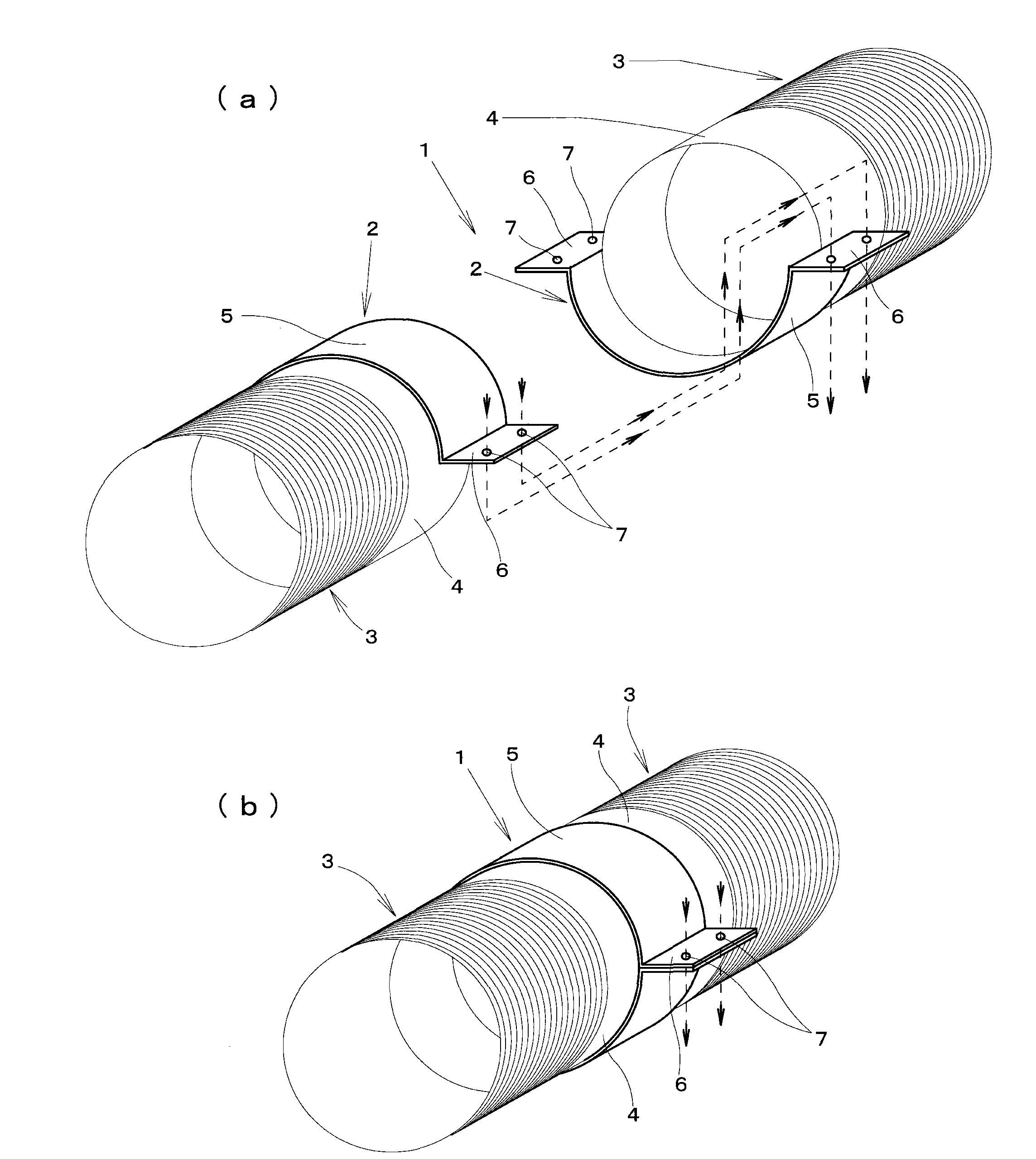

[0043] figure 1 It is a perspective view showing a basic embodiment of the pipe joint of the present invention, figure 1 (a) is a figure which shows the state before connecting a joint, figure 1 (b) is a figure which shows the state after connecting a joint.

[0044] This embodiment is an embodiment corresponding to the second configuration in the above-mentioned "Summary of the Invention" column, and it is a preferable implementation in the case of using for connecting a plurality of pipes in a horizontal state at a construction site such as a sewer ditch. Way.

[0045] This embodiment and the embodiments described below are described as pipe joints for connecting curtain pipes, but the pipes to be connected are not limited to curtain pipes, and may be ordinary cylindrical steel pipes or resin pipes. . In addition, although the pipe joints used in this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com