Turbine compressor

A technology of a turbo compressor and a cylinder, applied in the field of gas compressors, can solve the problems of high cost, small impeller width, and inability to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

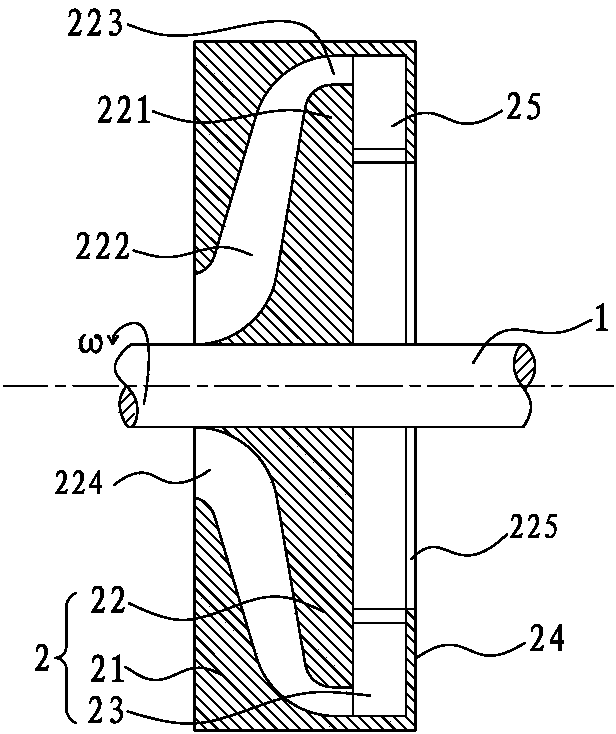

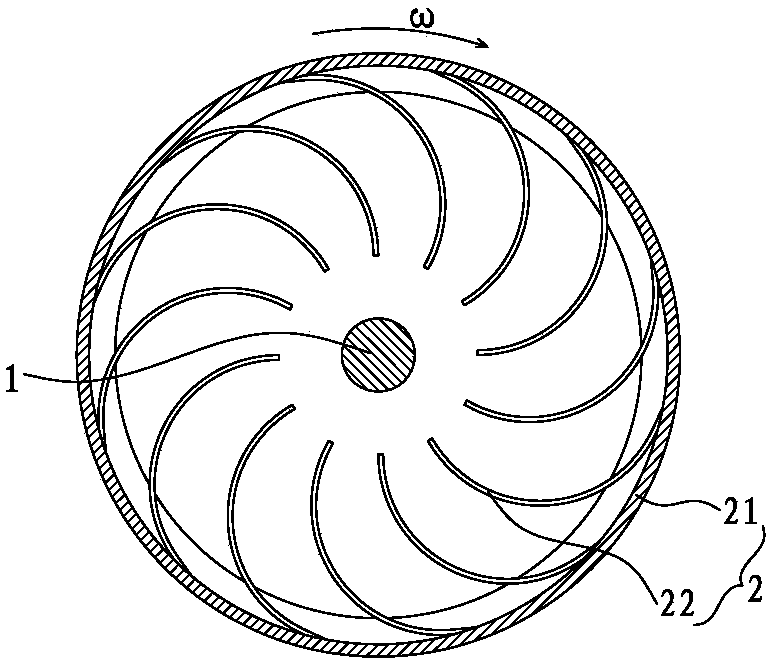

[0022] like figure 1 , figure 2 Shown, the present invention: the basic structure of the primary rotor of a kind of turbocompressor, it comprises rotating shaft 1, rotor 2.

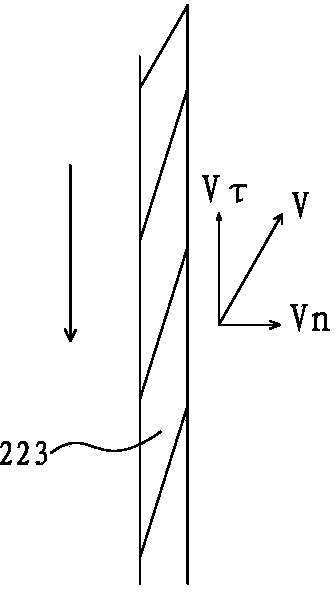

[0023] The rotor 2 is composed of a cylinder 21 , an impeller 22 , several forward arc-shaped blades 23 uniformly distributed along the circumference, and an end cover 24 . The cylinder 21 is installed outside the impeller 22, and the cylinder 21 and the impeller 22 are integrated and fixedly installed on the rotating shaft 1. The rotating shaft 1 is used to install and support all other components and drive them to rotate together at high speed. Described end cover 24 is installed on the gas outlet end of cylinder 21, and cylinder 21, end cover 24 and other elements form the air chamber of external closure together, and gas can only enter and exit through air inlet 224, air outlet 225. A plurality of blades 221 on the impeller 22 and the cylinder 21 together form a plurality of flow passages, each flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com