Tensioner pulley with asymmetrical damping mechanism

A damping mechanism and tensioner technology, applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of high cost, small frictional damping force, vibration of the drive system, etc., to improve reliability and environmental protection performance, high friction damping force, and the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

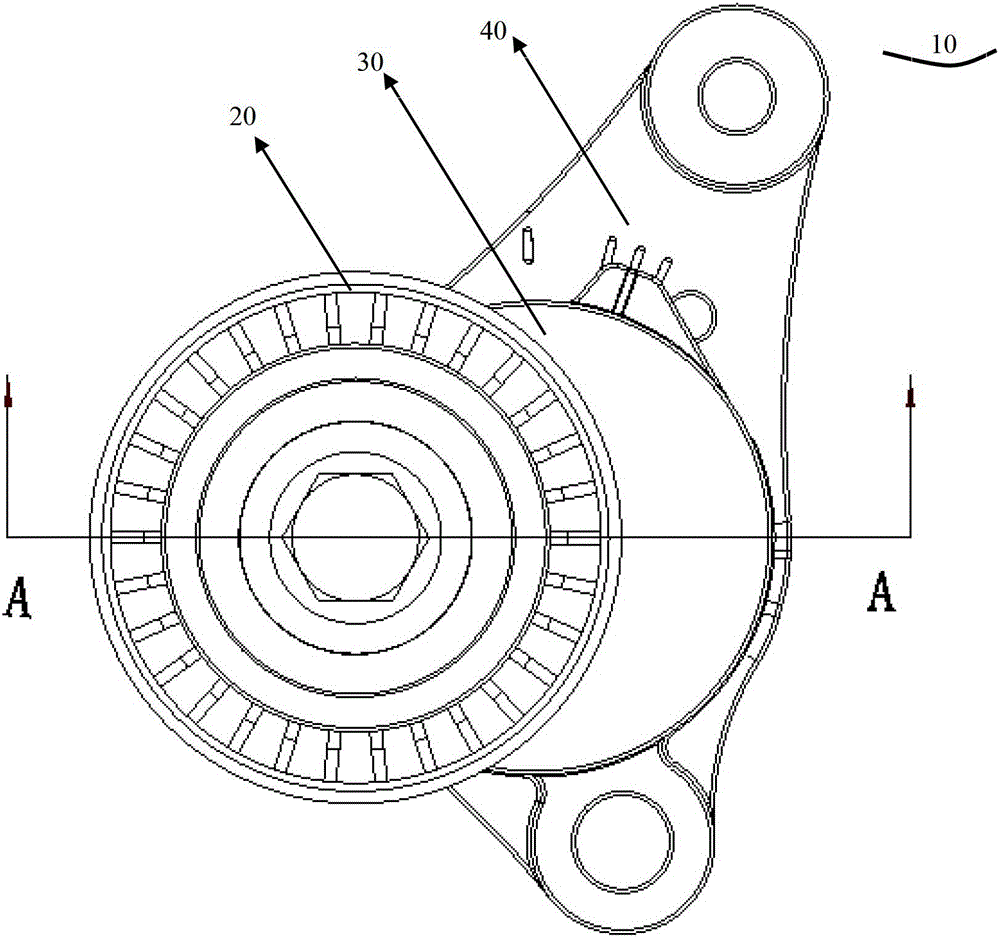

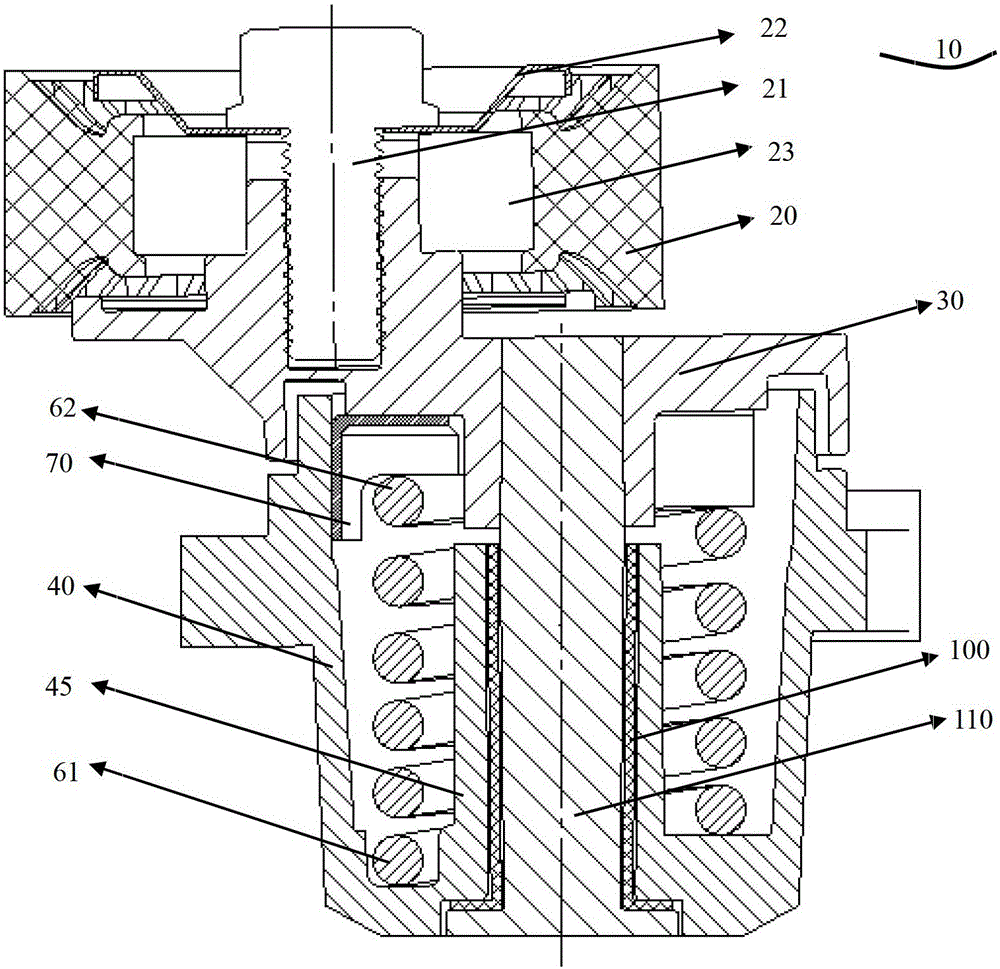

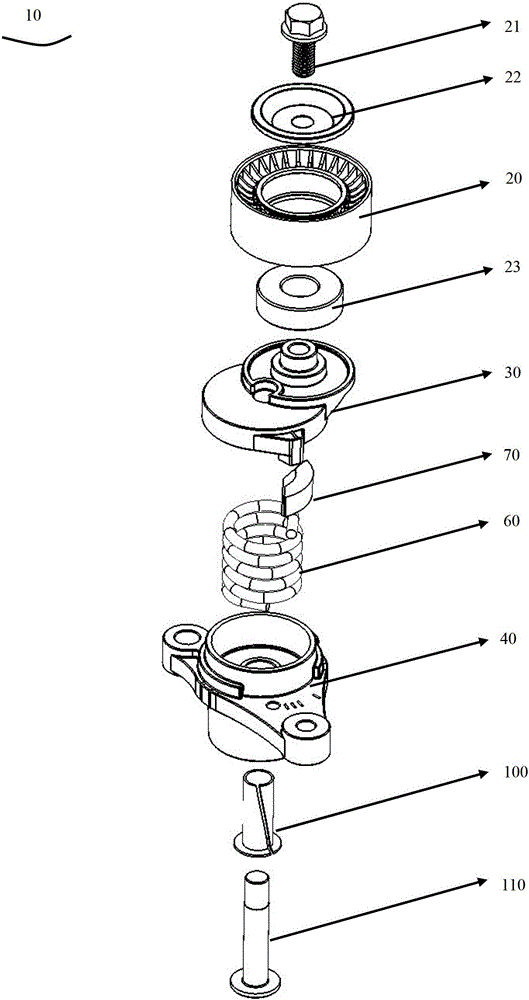

[0047] According to the tensioning wheel of the present invention in figure 1 , figure 2 with image 3 The overall number is marked with 10. figure 1 It is a structural schematic diagram of the tensioning wheel with an asymmetric damping mechanism of the present invention. Generally speaking, the tensioner 10 includes a pulley 20 , a swing arm 30 and a base 40 . further reference figure 2 with image 3 , the pulley 20 is fixedly connected with the swing arm 30 through the pulley bolt 21, and the pulley bolt 21 can adopt different rotation directions and fastening methods according to actual needs. In this embodiment, self-tapping screws are selected, because It forms or taps its matching thread by itself, so it has high anti-loosening ability in combination, and can be assembled and disassembled, and the process of processing an internal thread hole on the journal 31 of the swing arm 30 is also omitted. A dust cover 22 is arranged between the pulley bolt 21 and the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com