A gear selection structure and a gear selection method

A gear selection and gear position technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as position problems and gear selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

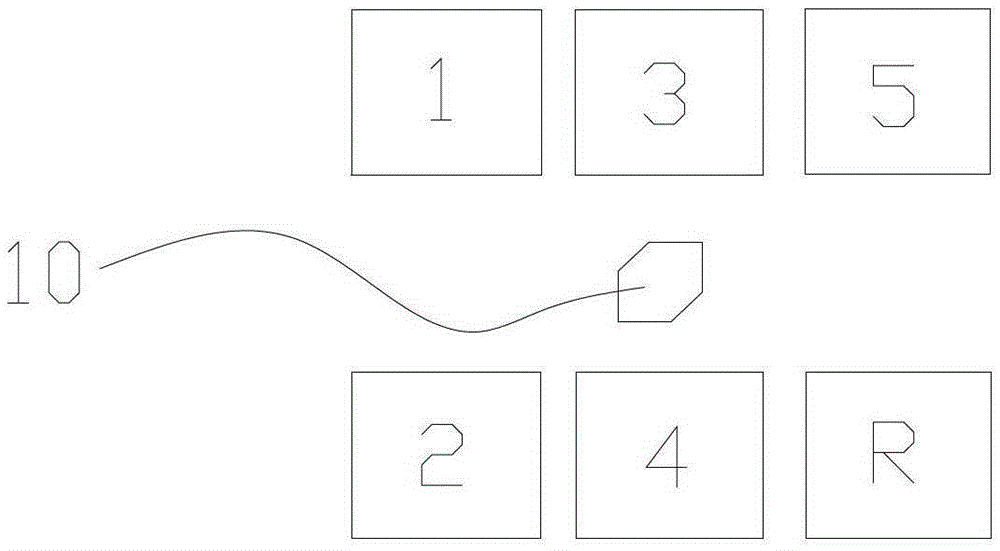

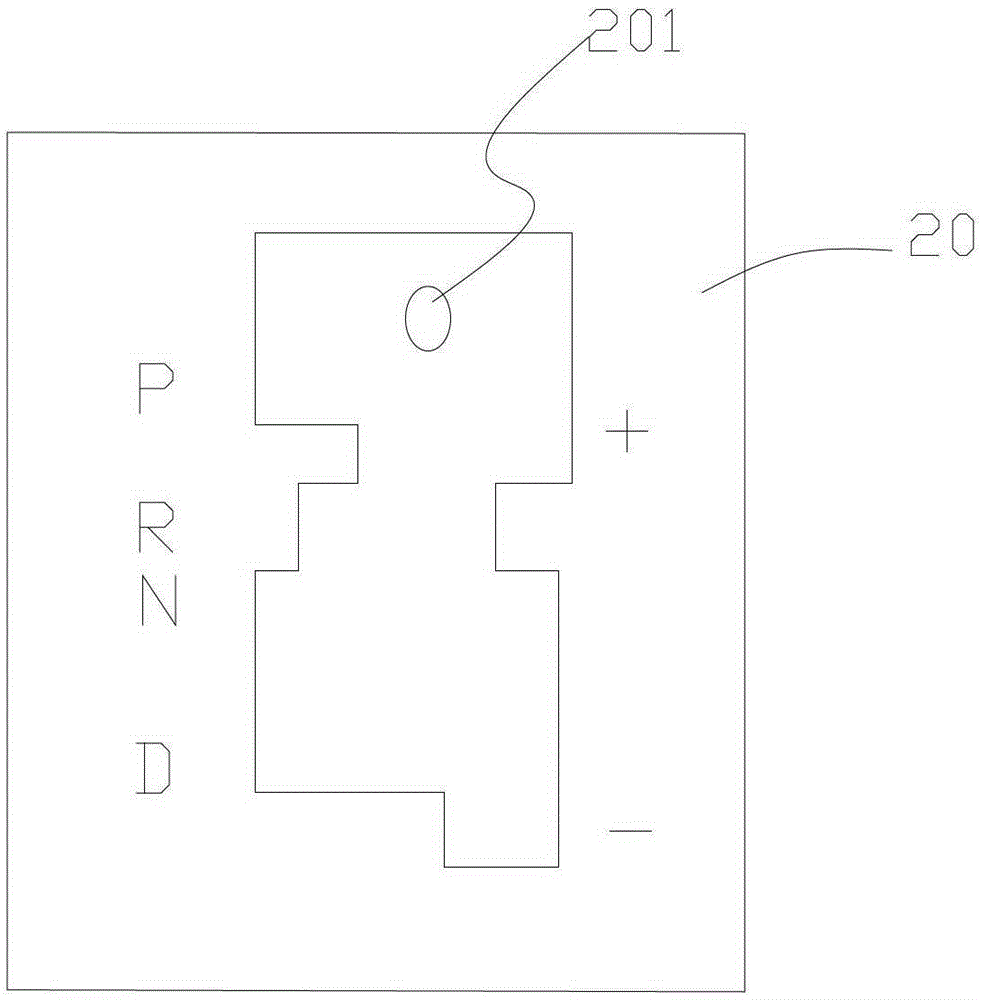

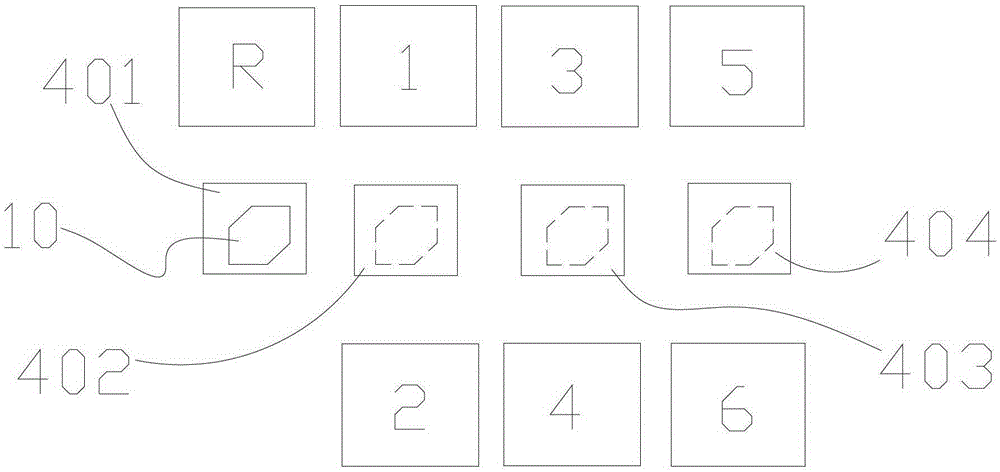

[0038] Such as Figure 4 As shown, a gear selection structure is suitable for mechanical automatic transmissions, including:

[0039] Reverse gear yoke frame 301, first gear and second gear yoke frame 302, third gear and fourth gear yoke frame 303, fifth gear and sixth gear yoke frame 304;

[0040] Gear selection finger 10;

[0041] A position sensor, the position sensor is used to detect the position information of the gear selection finger 10 and transmit the information to the controller. The position sensor is a linear displacement sensor;

[0042] A controller (not shown in the figure), the controller is used to control the movement of the gear selection finger 10, the gear selection finger 10 moves each fork frame, the fork frame drives the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com