Guardrail type step pitch gauge

A step gauge and guardrail-type technology, which is applied in the field of measuring tools, can solve the problems of loss of precision, poor working dimensional stability of step gauge, and no passage, etc., and achieves the effect of easy storage and carrying, easy promotion and use, and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

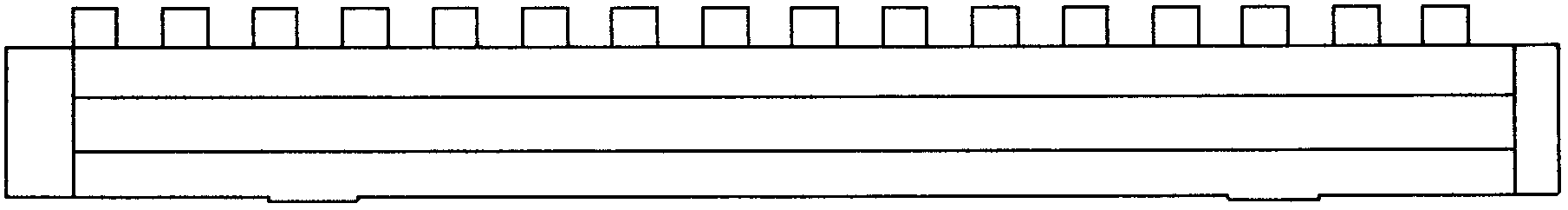

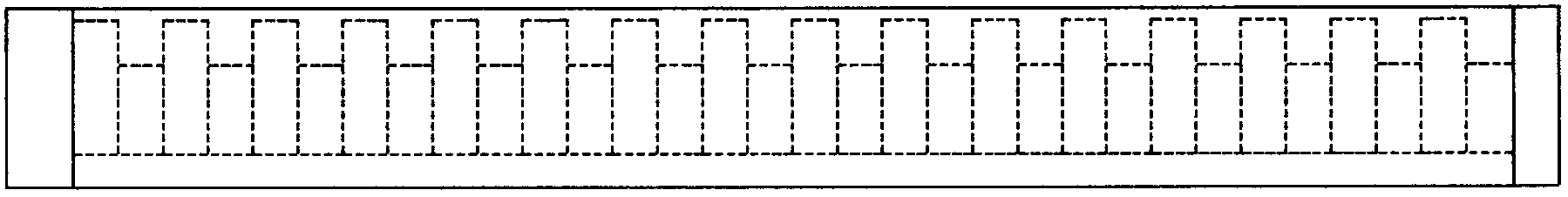

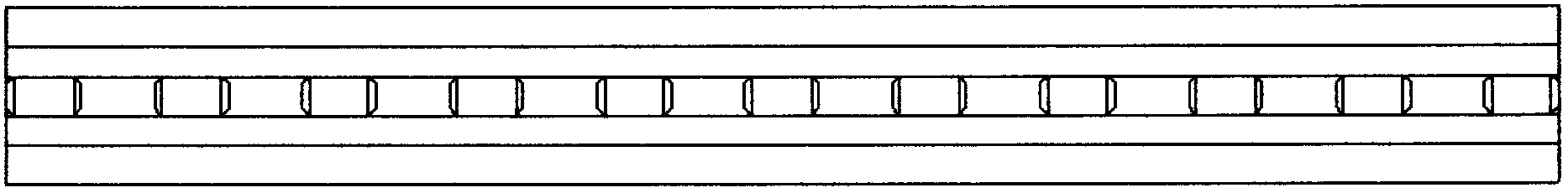

[0016] From image 3 , Figure 4 , Figure 6 It can be seen that the reference end cover 1 is connected with the left end surface of the base 2 with the hexagon socket head cap screw 6, the auxiliary end cover 3 is connected with the right end surface of the base 2, the spacer 4 and the working block 5 are ground together and placed on the base 2 According to the specification of the step gauge, the working block 5 is grinded together with the spacer 4 to make it grinded to a very precise precision, and the jacking screw 7 is threadedly connected with the middle end of the auxiliary end cover 3 .

[0017] From Figure 4 , Figure 5 It can also be seen that there are guardrails arranged at intervals on the upper ends of both sides of the base 2 . The guardrail and the base 2 are an integral structure. With the guardrail working block 5, it will not be subject to external force collision, so that the accuracy of the step gauge can be maintained for a long time. It is very ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com