Gas chromatograph with plasma emission detector

A gas chromatograph and plasma technology, which is applied in the field of gas chromatographs of plasma emission detectors, can solve problems such as chromatographic column oxygen absorption, achieve convenient operation, low cost, and solve the effect of separating oxygen and argon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

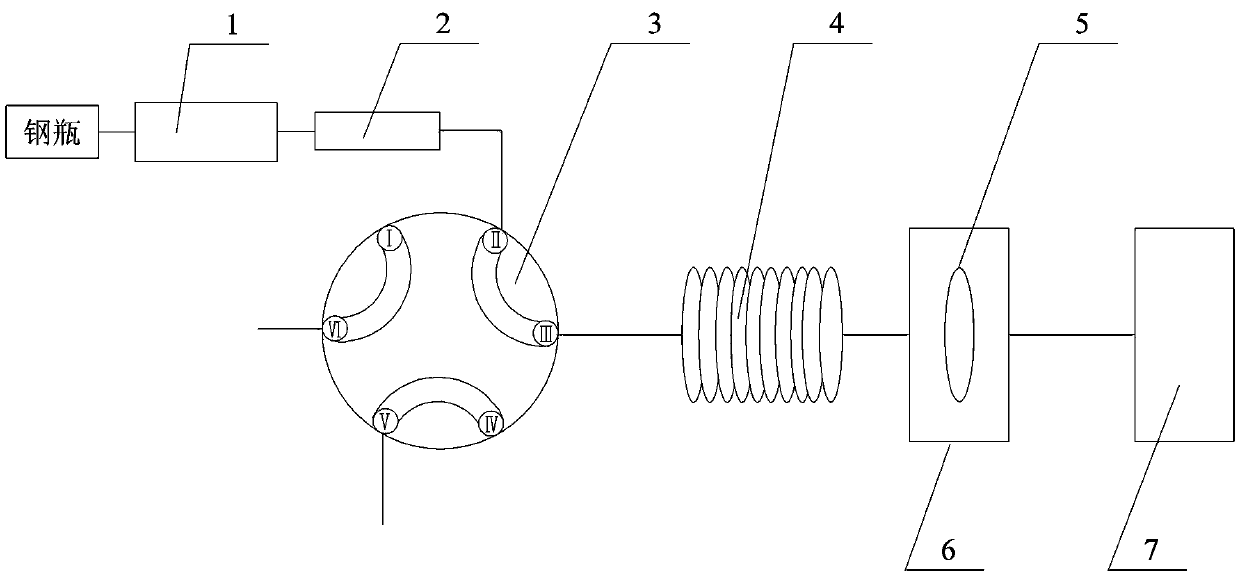

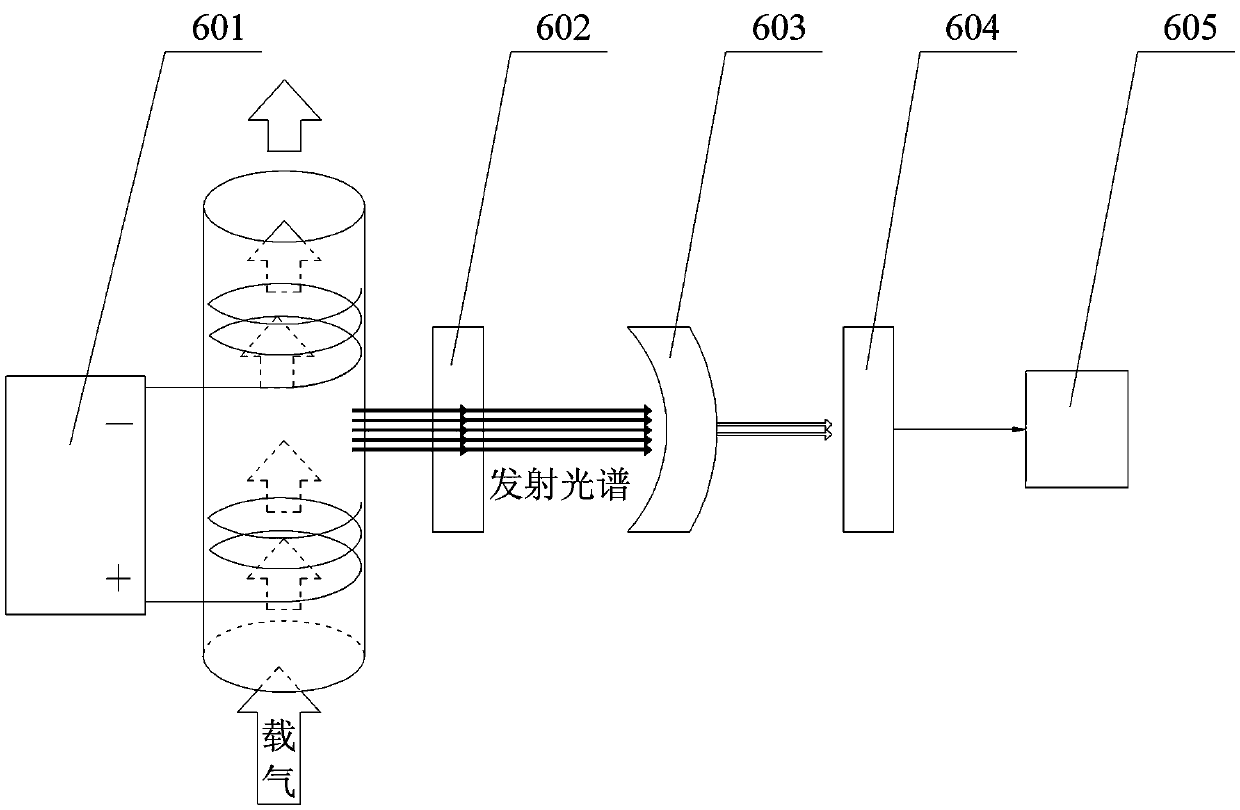

[0017] According to attached figure 1 And attached figure 2 , a gas chromatograph with a plasma emission detector in the present invention, including a built-in purifier 1 connected in sequence, an oxygen adsorption prevention device 2, a six-way valve 3, an oxygen-argon separation device 4, a plasma emission detector 6 and Digital voltage output means 7 , plasma emission detector 6 includes selective filter means 5 .

[0018] The measured carrier gas carries the sample gas out of the cylinder, first passes through the built-in purifier 1 and prevents oxygen adsorption device 2, effectively removes the content of impurity gases in the carrier gas, and then passes through the six-way valve 3 for gas sampling, When the six-way valve 3 is switched to the sample injection state, the trace oxygen can quickly pass through the port III of the six-way valve 3 and enter the oxygen-argon separation column of the oxygen-argon separation device 4 . After the sample gas completes the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com