DC-DC Converter

A DC-DC, converter technology, applied in the field of DC-DC converters, can solve the problems of error amplification, large surge voltage, intense noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

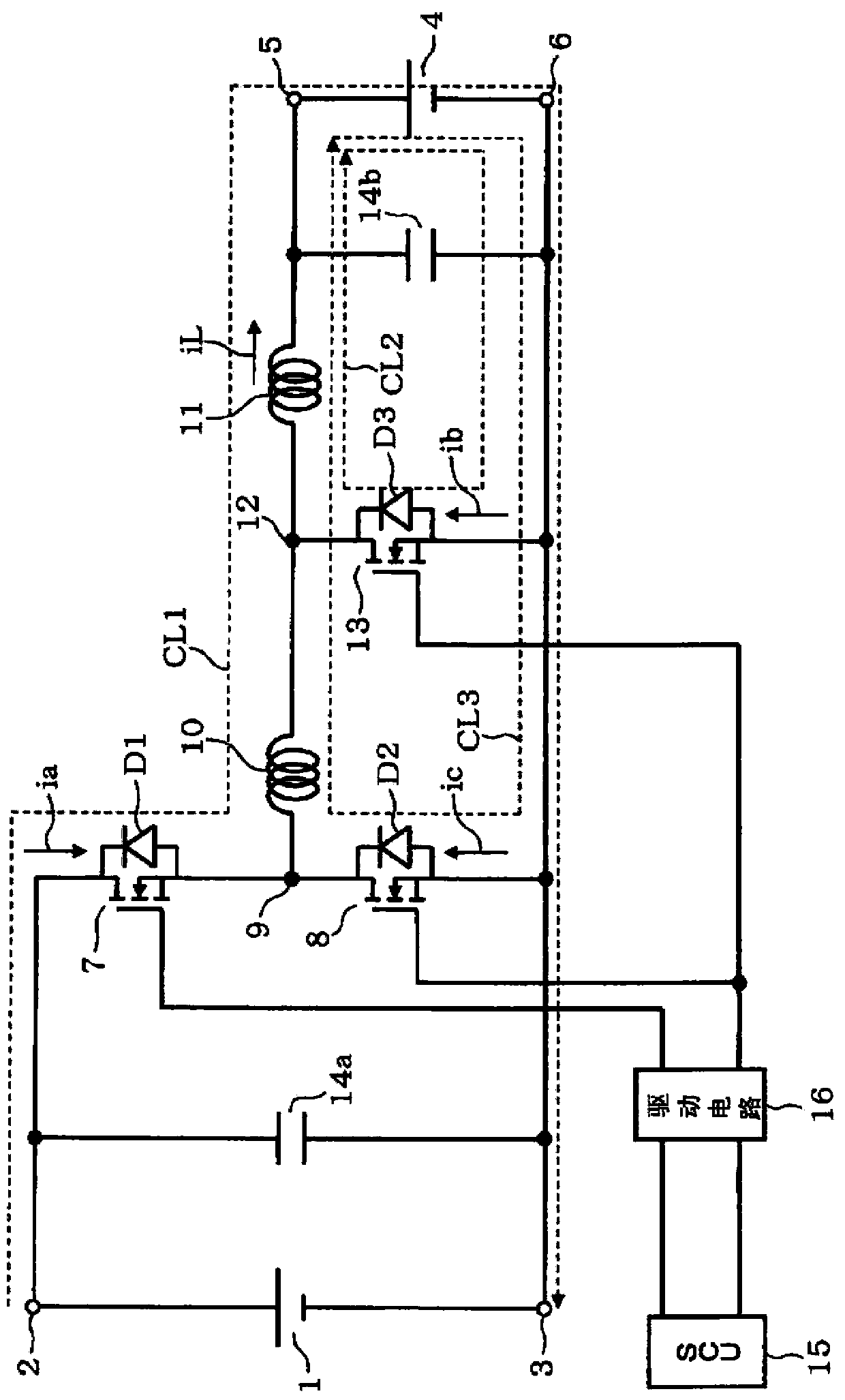

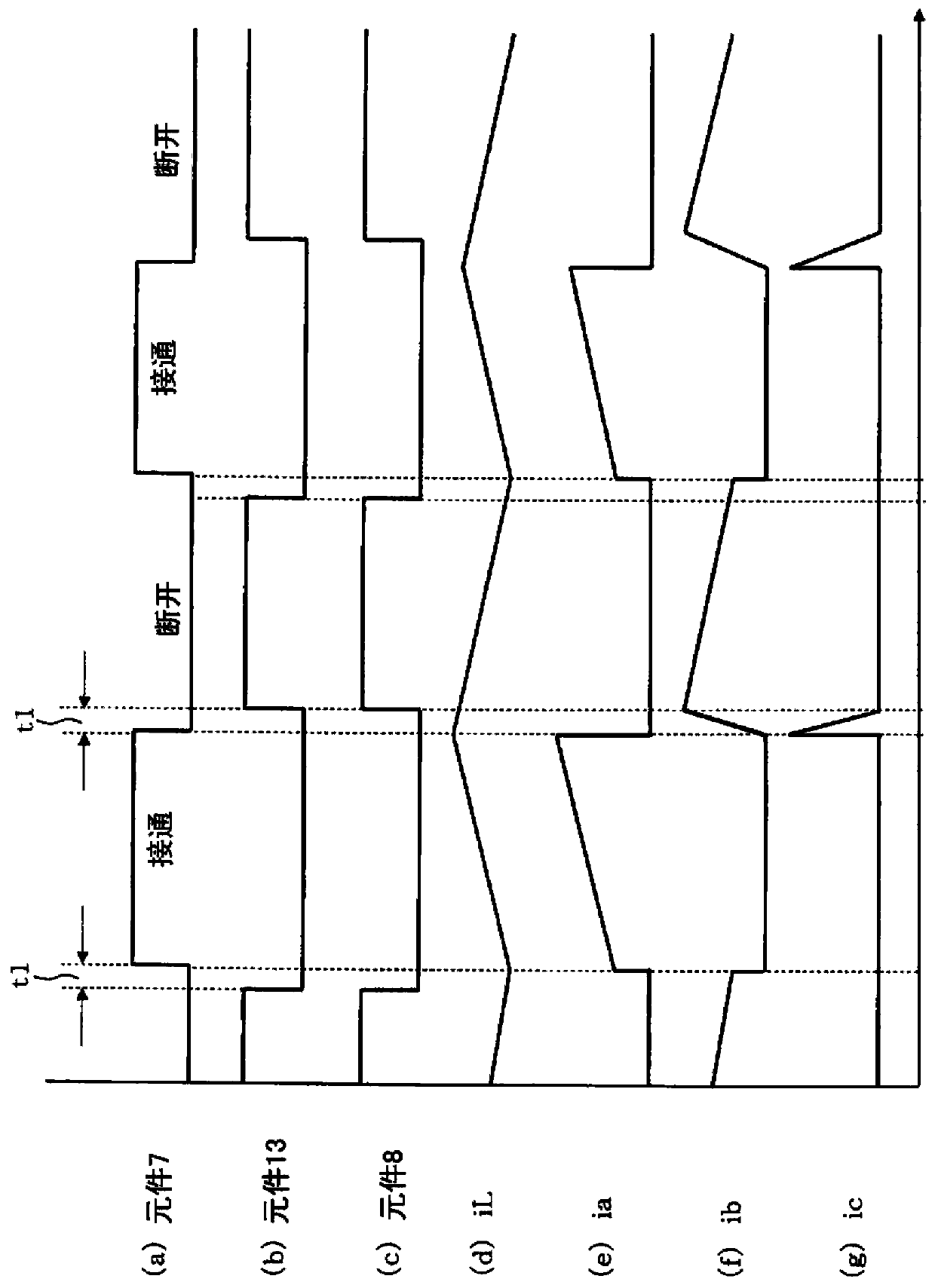

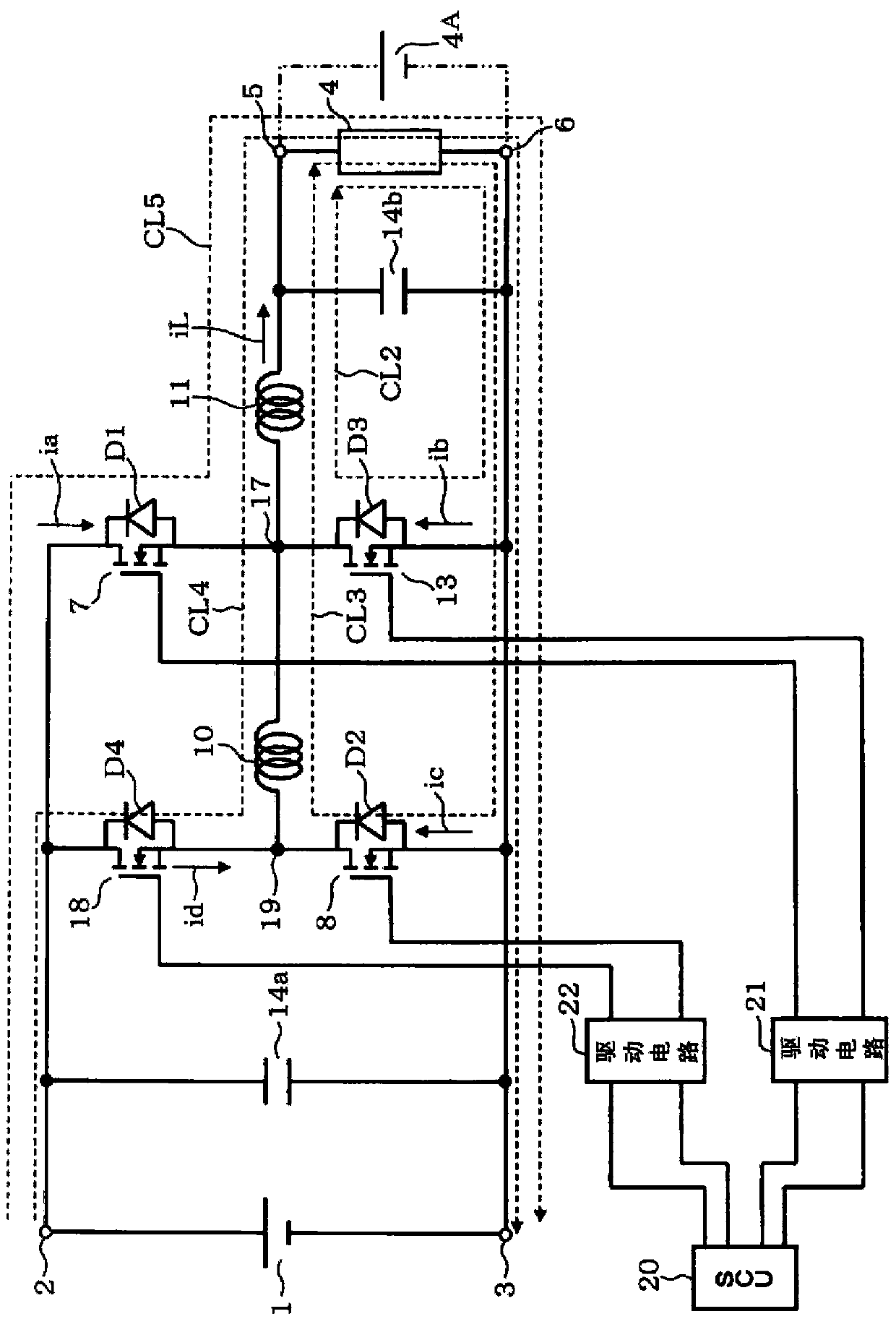

[0015] In showing the first embodiment figure 1 Among them, the DC-DC converter has a DC voltage positive side input terminal 2 connected to a DC power supply 1 and a DC voltage negative side input terminal 3 on its input side, and has a DC voltage positive side output terminal 5 connected to a load 4 on the output side And DC voltage negative side output terminal 6. Here, the positive side and the negative side only mean relatively high and low potentials. The DC power source 1 refers to a DC power source including a battery, an AC-DC conversion and rectification circuit, and the like. The load 4 includes a resistive load, an inductive load such as a motor, a battery to be charged, or the like.

[0016] The first main switching element 7 and the auxiliary switching element 8 are connected in series between the positive DC voltage input terminal 2 and the negative DC voltage input terminal 3 such that the former is on the positive side and the latter is on the negative side....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com