Heating circulating pump

A heat supply cycle, pump housing technology, applied in the direction of pumps, pump elements, pump devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

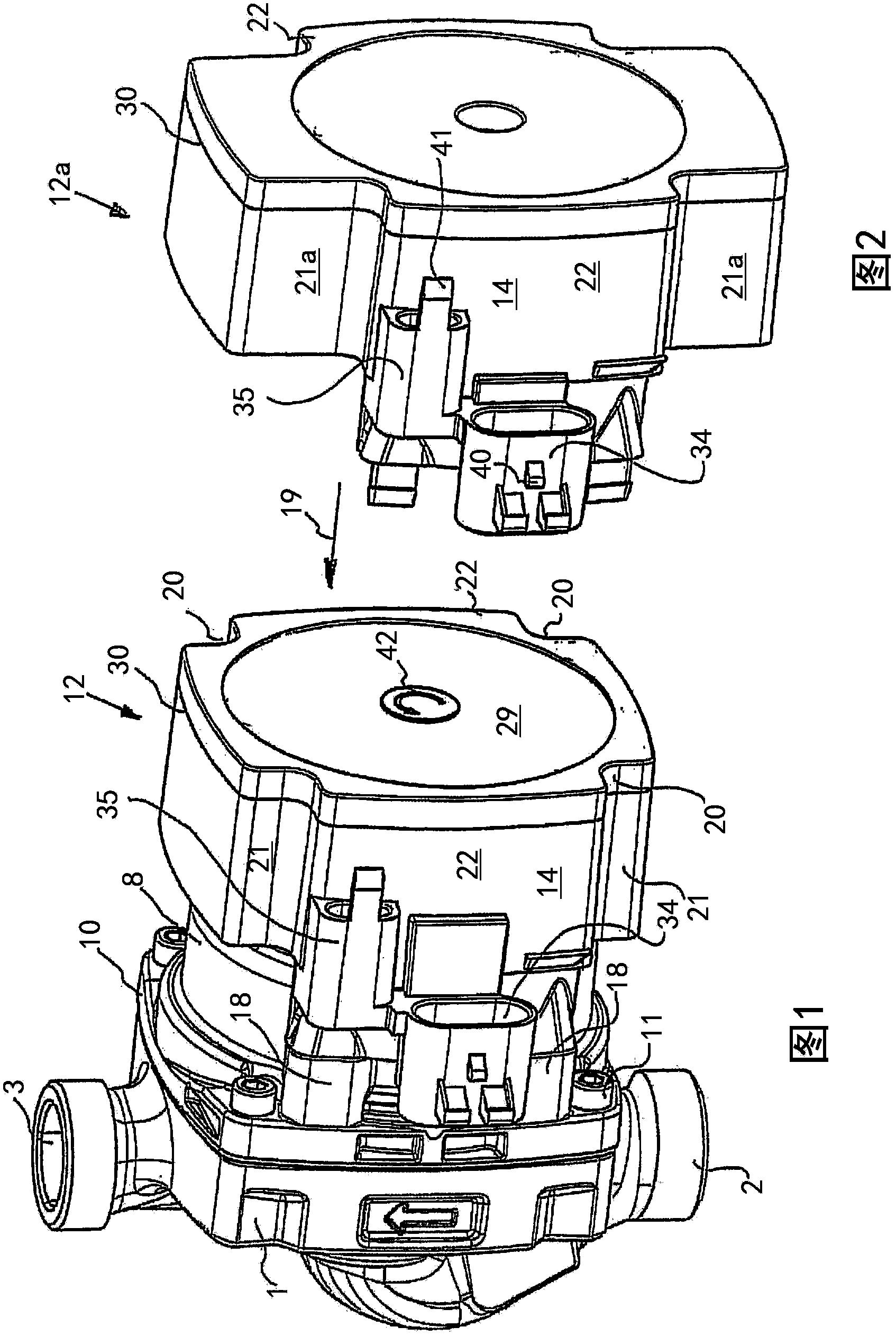

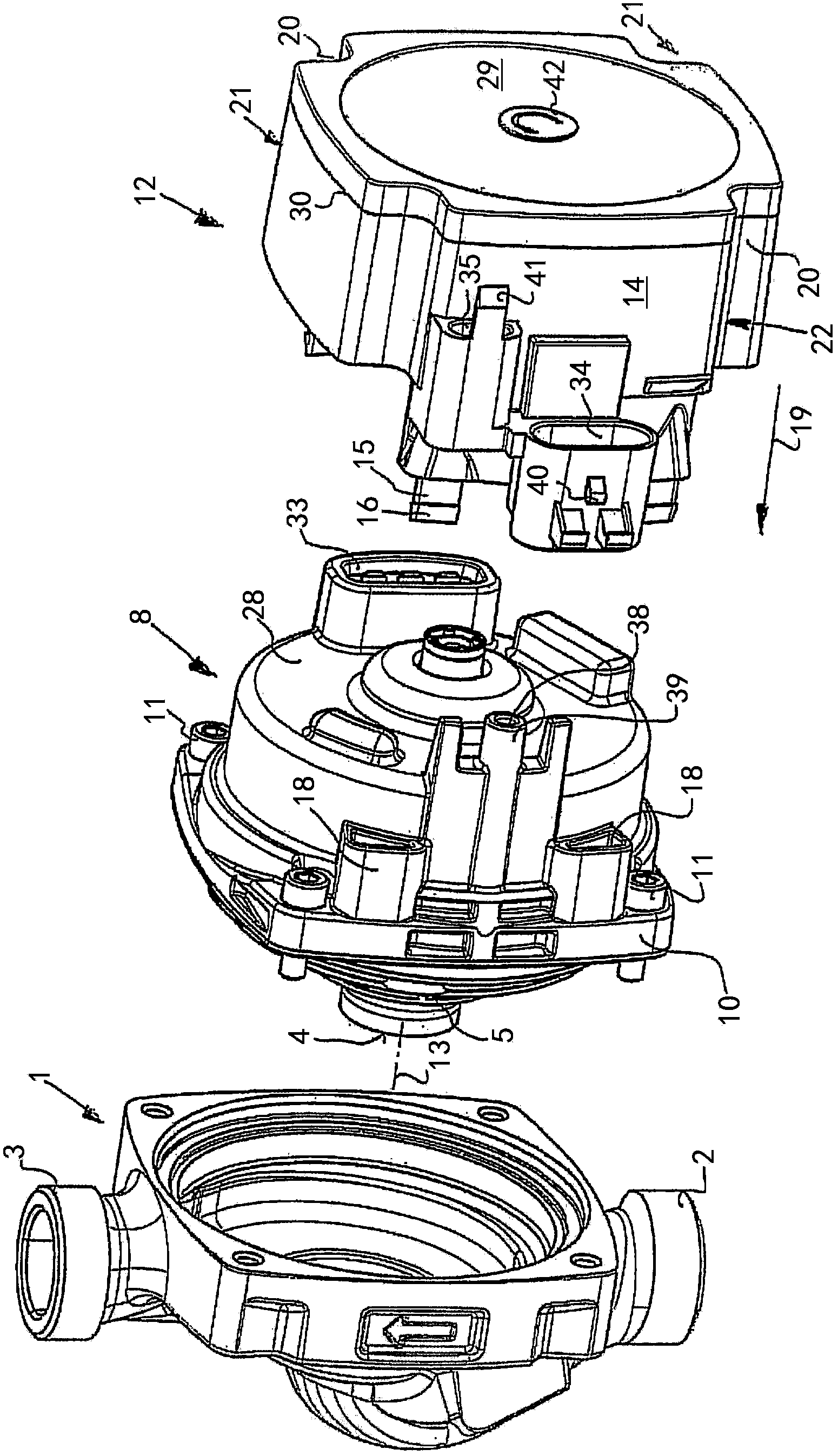

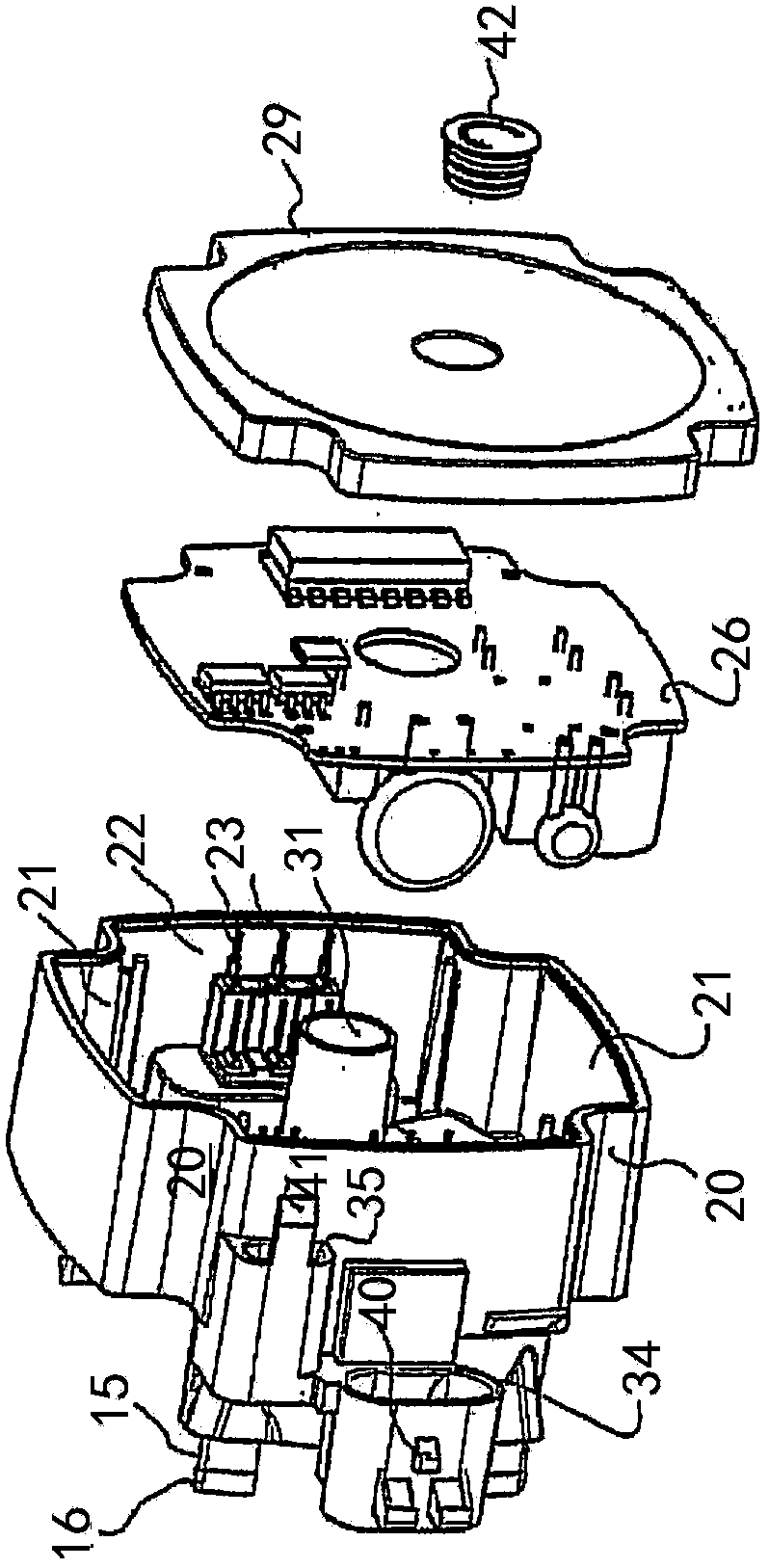

[0027] like figure 1 as well as Figure 3 to Figure 8 The heating circulation pump shown has a centrifugal pump comprising a pump housing 1 with a suction sleeve 2 and a pressure sleeve 3 and a guide channel arranged between them, which will lead from the suction The liquid from the casing 2 is fed to the suction 4 of a pump impeller 5 mounted inside the pump housing 1 , the output side of which is connected to the channel leading to the pressure casing 3 .

[0028] The heating circulation pump has an electric motor, here a wet-running electric motor, whose rotor 6 runs in a liquid-filled slot 7 . The can tube 7 is surrounded by a stator (ie a motor winding arranged around the can tube 7 ) and a motor housing 8 for accommodating the stator. The rotor 6 has an intermediate shaft 9 which extends into the pump housing 1 and carries the pump impeller 5 in order to transmit the rotational movement of the rotor 6 to the pump impeller 5 .

[0029]The motor housing 8 has a flange 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com