Humidifying bottle enabling oxygen to be sufficiently humidified

An oxygen and moisture technology, applied in the field of moisture bottles, can solve the problems of unfavorable rest for patients, easy pollution, poor safety, etc., and achieve the effect of convenient use, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

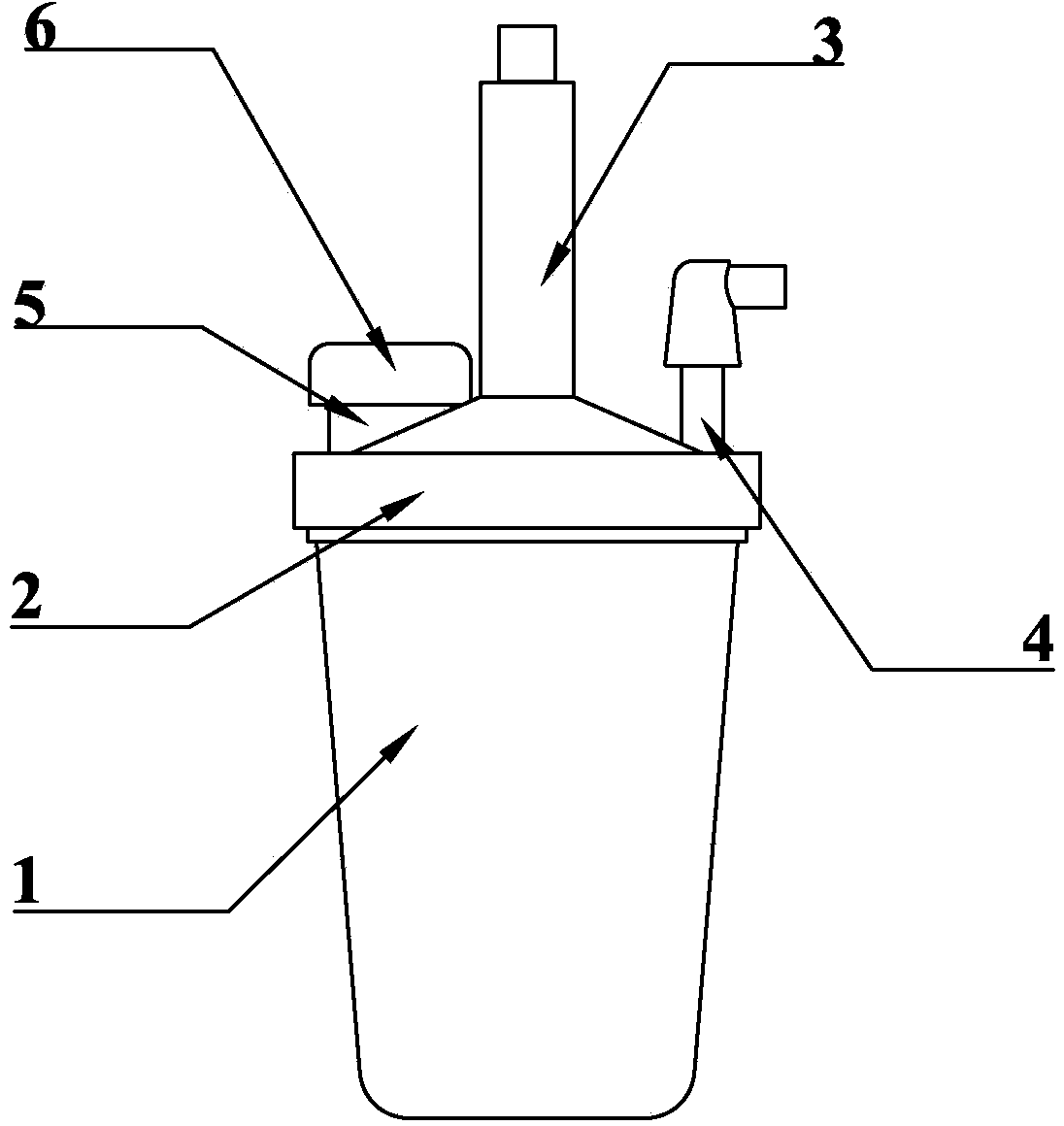

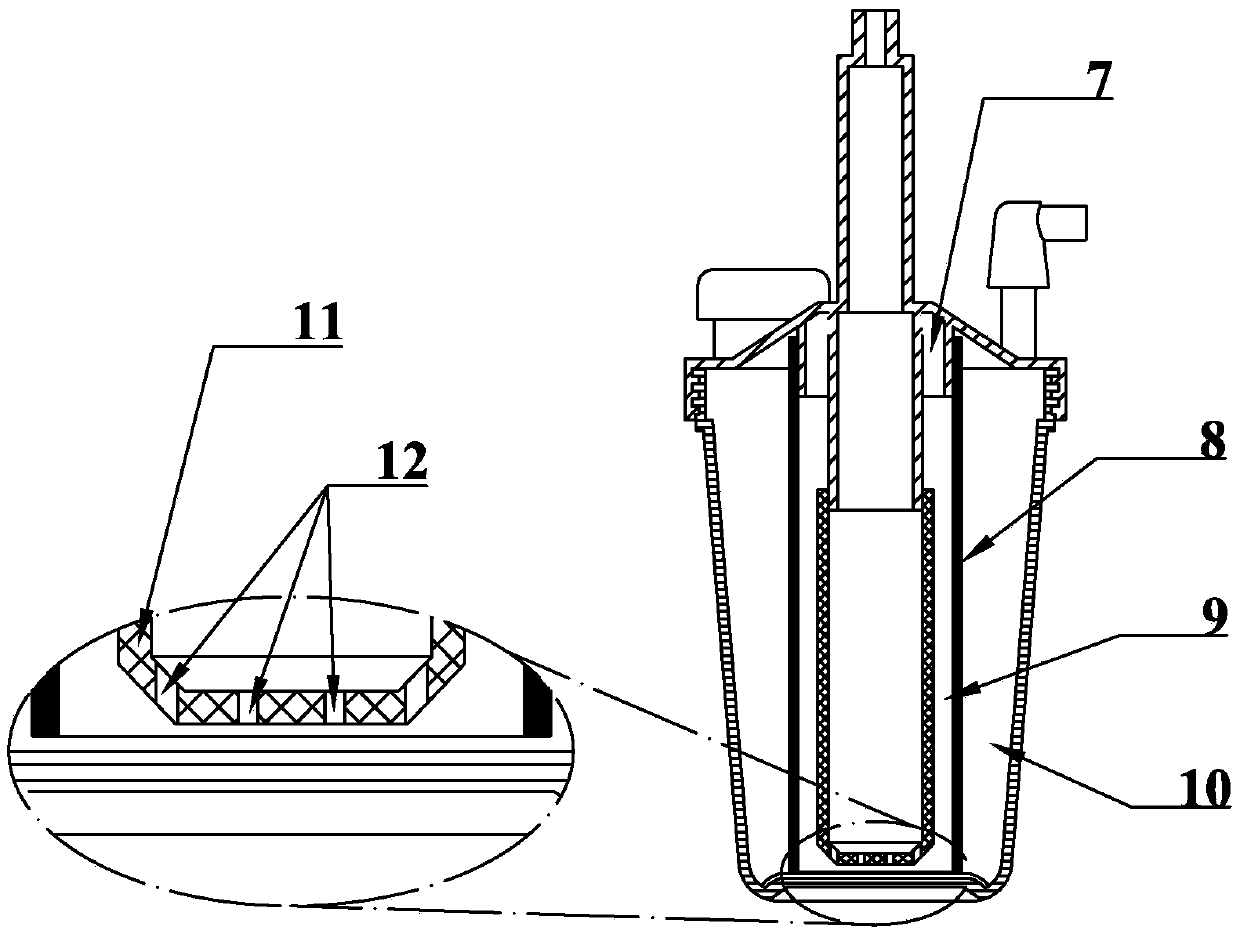

[0015] Implementation mode one: if Figure 1 to Figure 2 As shown, the humidification bottle with sufficient oxygen dehumidification includes a bottle body 1 and a bottle cap 2, the bottle cap 2 is sealed and sealed on the upper part of the bottle body 1, and the bottle cap 2 is provided with an oxygen inlet pipe 3 and an oxygen outlet pipe 4 And the liquid filling port 5, wherein the liquid filling port 5 is provided with a liquid filling port cover 6; the inner wall of the bottle cap 2 is provided with a connecting part 7, and the connecting part 7 is connected with a rough and elastic cylindrical partition 8 The bottom of the partition 8 is not in contact with the bottom of the bottle body 1, the partition 8 divides the inner space of the bottle body 1 into a connected inner cavity 9 and an outer cavity 10, and the oxygen inlet pipe 3 extends into the inner cavity 9, Its bottom is connected with a muffler pipe 11, the end of the muffler pipe 11 is a blind end, and a number ...

Embodiment approach 2

[0016] Embodiment 2: The oxygen outlet pipe 3 is vertically arranged on the bottle cap 2, and a corner joint is provided at its end. The remaining components and structures are as described in Embodiment 1, omitted.

Embodiment approach 3

[0017] Embodiment 3: The bottom of the bottle body 1 is concave, forming a bottom groove. The remaining components and structures are as described in Embodiment 2, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com