Metal wire drawing die seat device

A technology of metal wire and die base, applied in the direction of wire drawing dies, etc., can solve problems such as inability to draw, and achieve the effects of reducing consumables, reducing costs, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

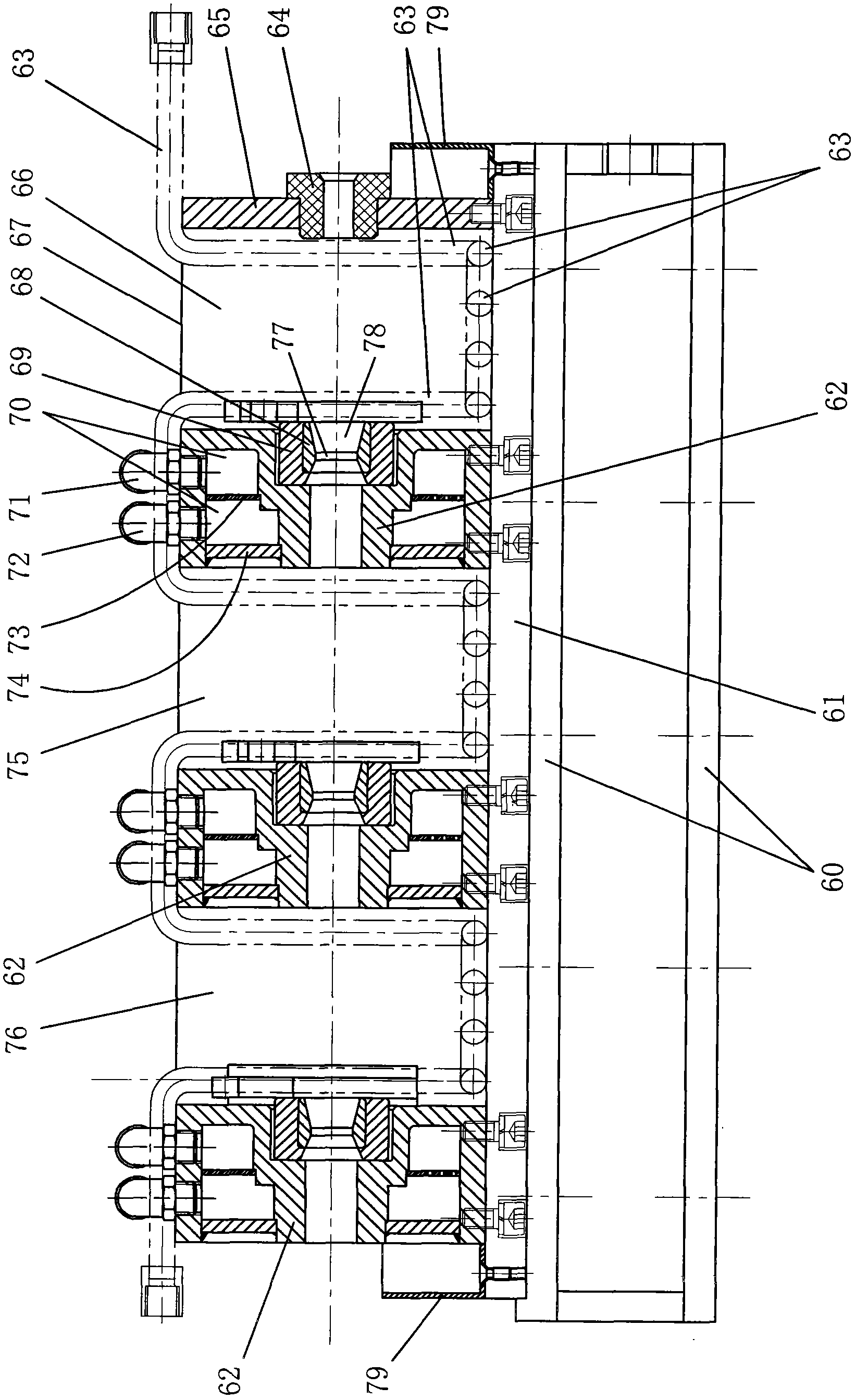

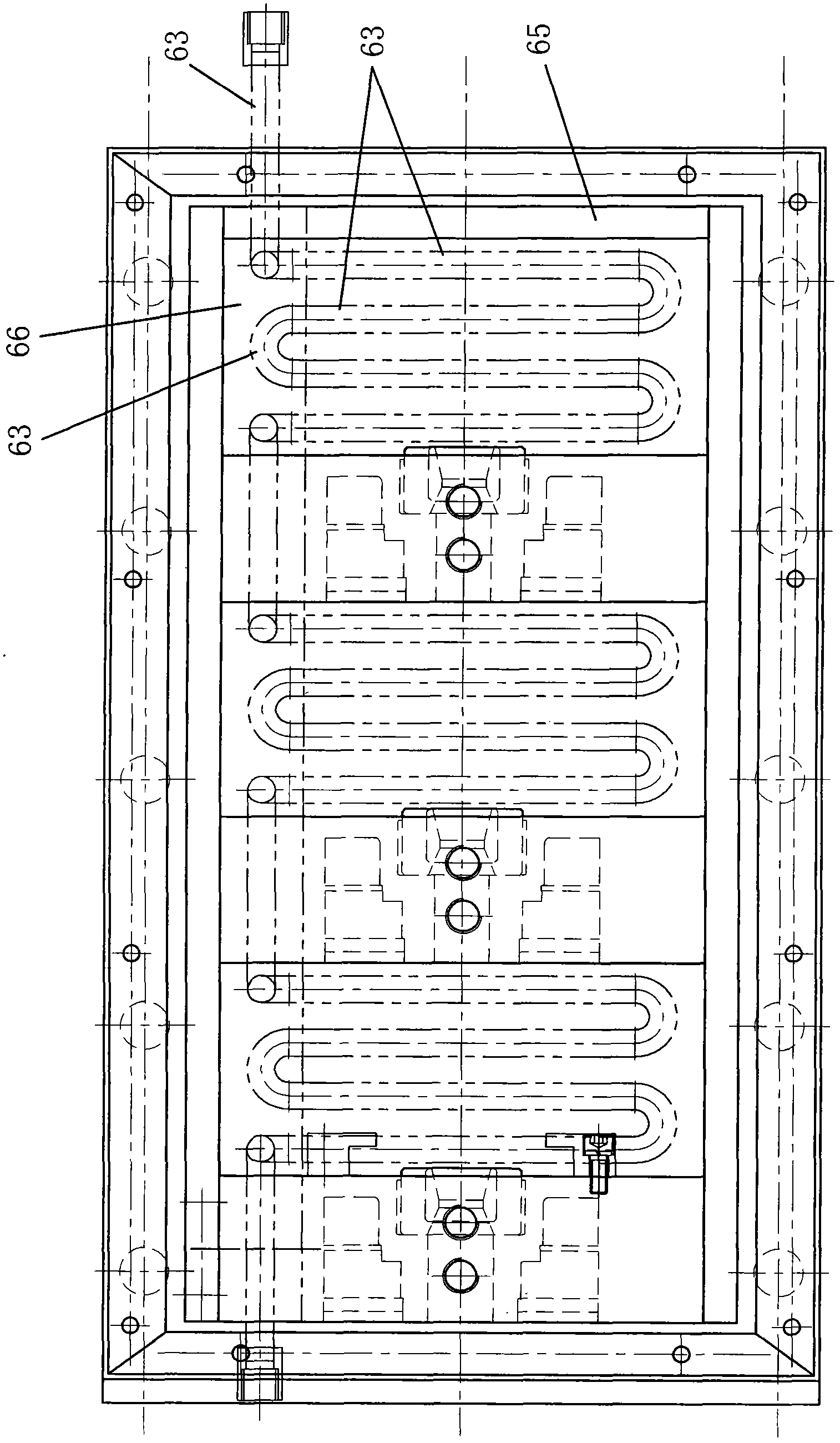

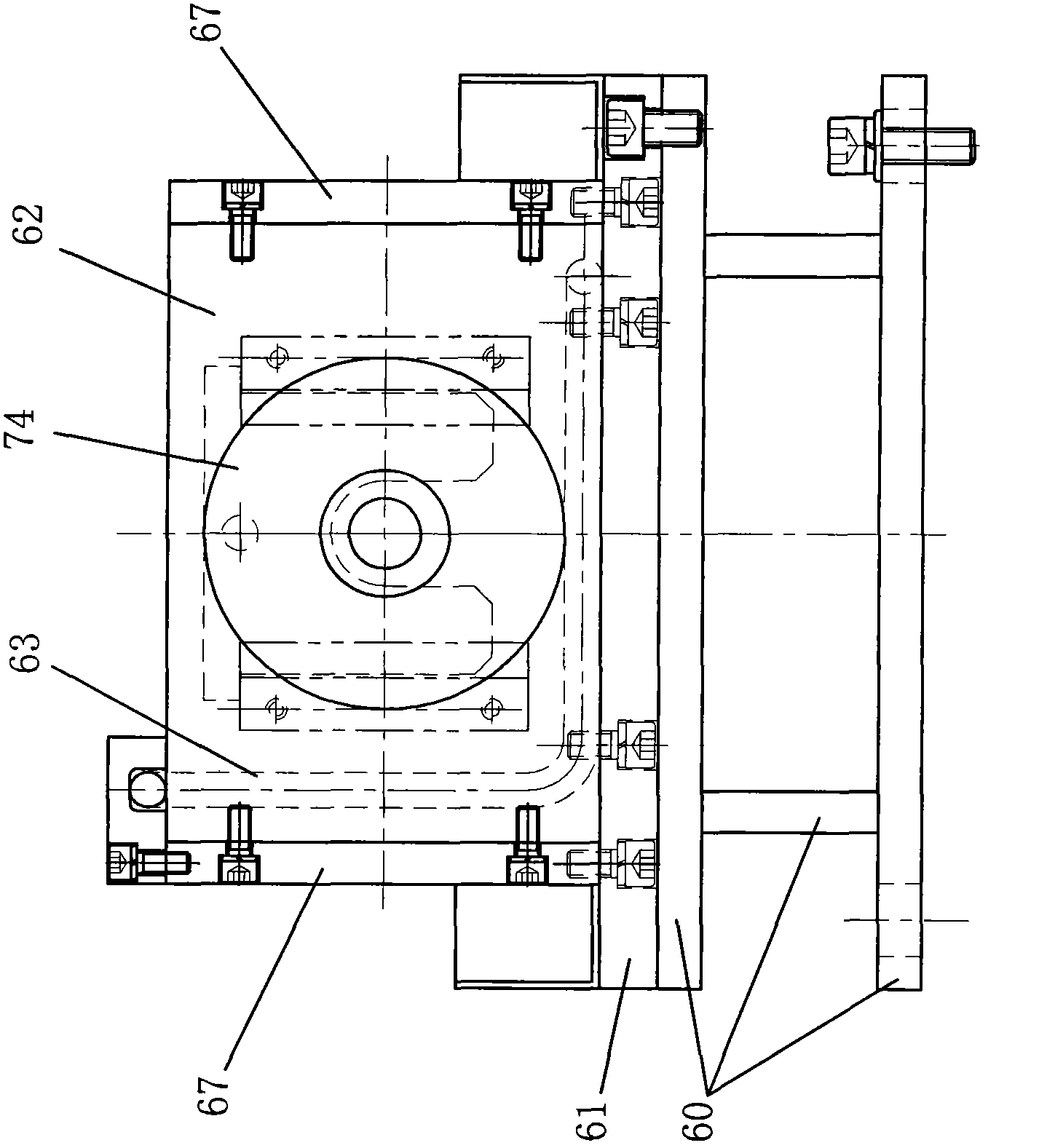

[0014] Such as figure 1 , 2 . As shown in 3: 60 is a base, and a bottom plate 61 is fixedly connected to the base 60 by bolts. On the base plate 61, three (group) die holders 62 are fixedly installed by bolts, and die cover 69 is all housed in the center hole front side concave hole of each die holder 62, and drawing die 68 is positioned in the die cover 69. A die hole 77 is arranged at the center of the drawing die 68, and a tapered hole 78 is arranged on the front side.

[0015] There are drawing oil chambers between the adjacent die bases 62 and at the front end of the die base 62 located at the front end. Each drawing oil cavity is formed by the following structure: on both sides of each die base 62, there are side plates 67 fixedly connected with the die base 62 by bolts; The center hole is inlaid with the end plate 65 of the inlet sleeve 64, and the side plates 67, end plates 65, bottom plate 62 and each mold base 62 on both sides enclose the drawing oil chamber locat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com