Mold and method for manufacturing door closer shell

A technology for door closers and shells, which is applied in the field of molds and products manufactured with the molds, can solve the problems of high strength and hardness of door closer shells, high yield of door closer shells, and low production efficiency, and achieve It is beneficial to exhaust, fast filling speed and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

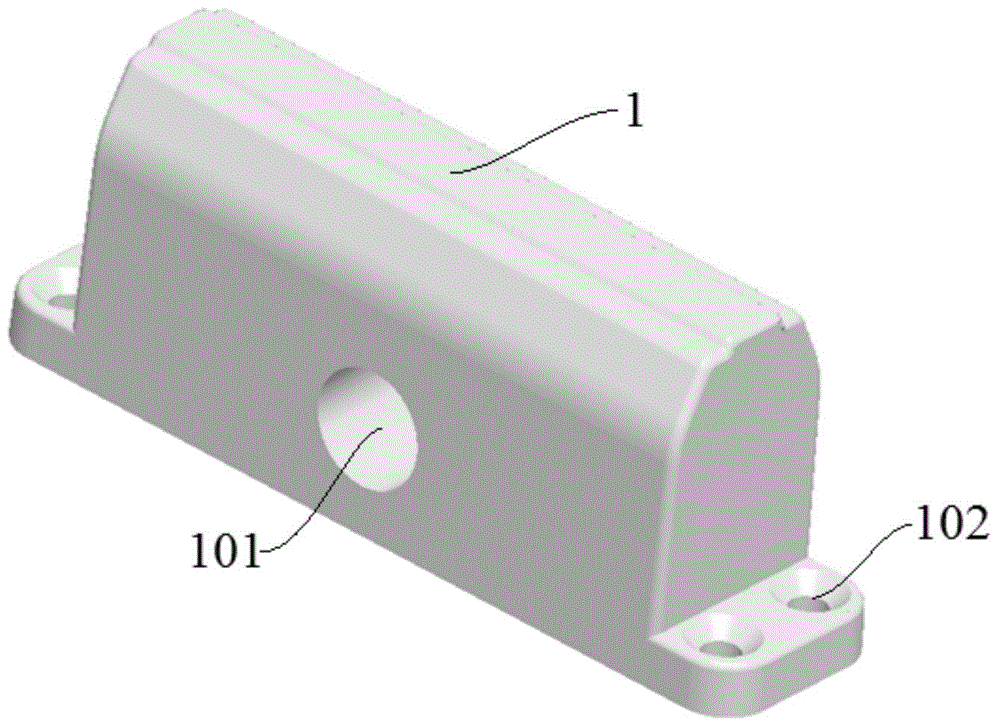

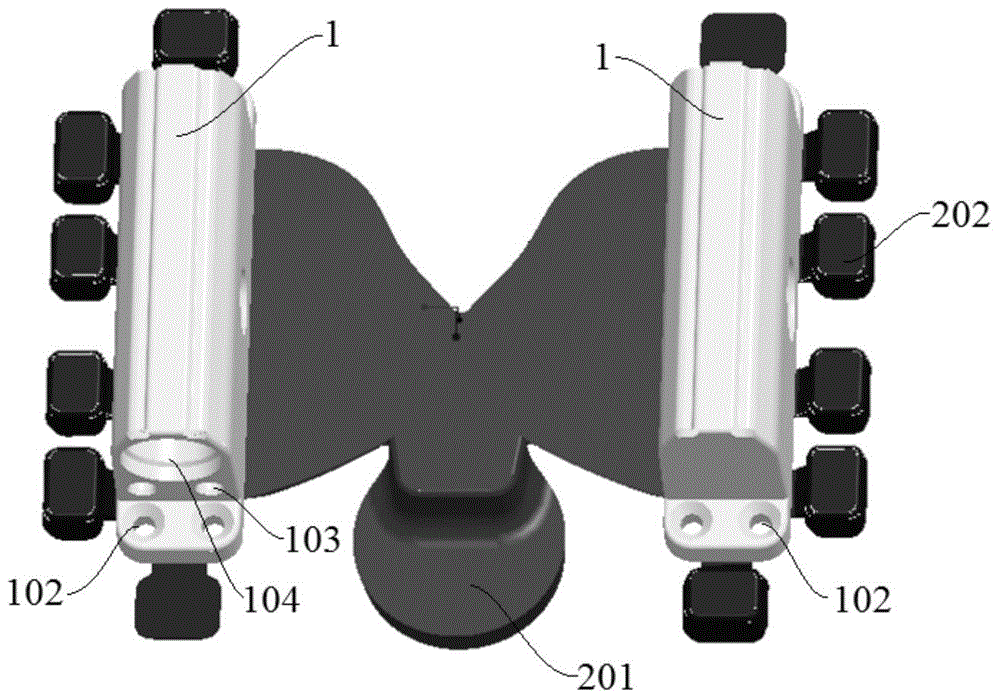

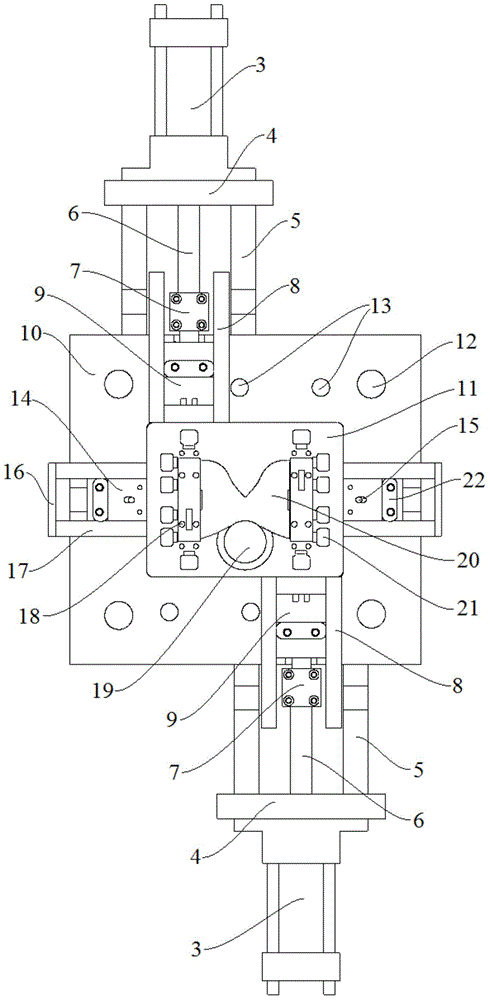

Embodiment 1

[0038] A mold for manufacturing a door closer housing in this embodiment includes a movable template 10, a movable mold core 11 embedded in the movable template 10, a fixed template 23, a fixed mold core 24 embedded in the fixed template 23, and a reset rod 13. Push rod 18, guide column 12 and guide sleeve 26 connecting movable formwork 10, fixed formwork 23, main flow channel 19, shunt flow channel 20, slag ladle groove 21, horizontal core-pulling mechanism, longitudinal core-pulling mechanism and two symmetrical centers cavity, the reset rod 13 and the push rod 18 are installed on one side of the movable template 10, the main flow channel 19 is opened on the fixed mold core 24, and is located at the lower position in the middle of the two center-symmetrical cavities. There are two cavities in the auxiliary mold, and the production efficiency is improved under the condition that the production cost is basically unchanged, and the benefit can be increased by about 40%. The run...

Embodiment 2

[0047] The basic structure of a mold for manufacturing the door closer housing of this embodiment is the same as that of Embodiment 1, the difference is that the inclination angle of the inclined guide column 15 of the mold in this embodiment is 20.5°, and the side of the cavity is provided with a Mold slope, demoulding slope is 1.2°; in the method for manufacturing the door closer shell of this embodiment, the mold cavity is preheated, the preheating temperature is 275°C, the molten aluminum alloy liquid is injected, and the injection pressure The temperature is 135 bar, the speed is 4m / s, and the cooling time is 5s. The aging treatment is to heat the door closer shell 1 to 175°C, keep it warm for 2.5h, and then cool it in the air.

Embodiment 3

[0049] The basic structure of a mold for manufacturing the door closer housing of this embodiment is the same as that of Embodiment 1, the difference is that the inclination angle of the inclined guide post 15 of the mold in this embodiment is 21°, and the side of the cavity is provided with a knockout Mold slope, demoulding slope is 1.5°; in the method for manufacturing the door closer shell of this embodiment, the mold cavity is preheated, the preheating temperature is 350°C, the molten aluminum alloy liquid is injected, and the injection pressure The temperature is 140bar, the speed is 5m / s, and the cooling time is 6s. The aging treatment is to heat the door closer shell 1 to 180°C, keep it warm for 2 hours, and then cool it in the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com