Steel ladle edge covering structure

A technology of ladle and cladding, which is used in casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of steel leakage along the slag line and bricks falling along the cladding, so as to improve the strength, reduce the number of repairs, and improve the effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

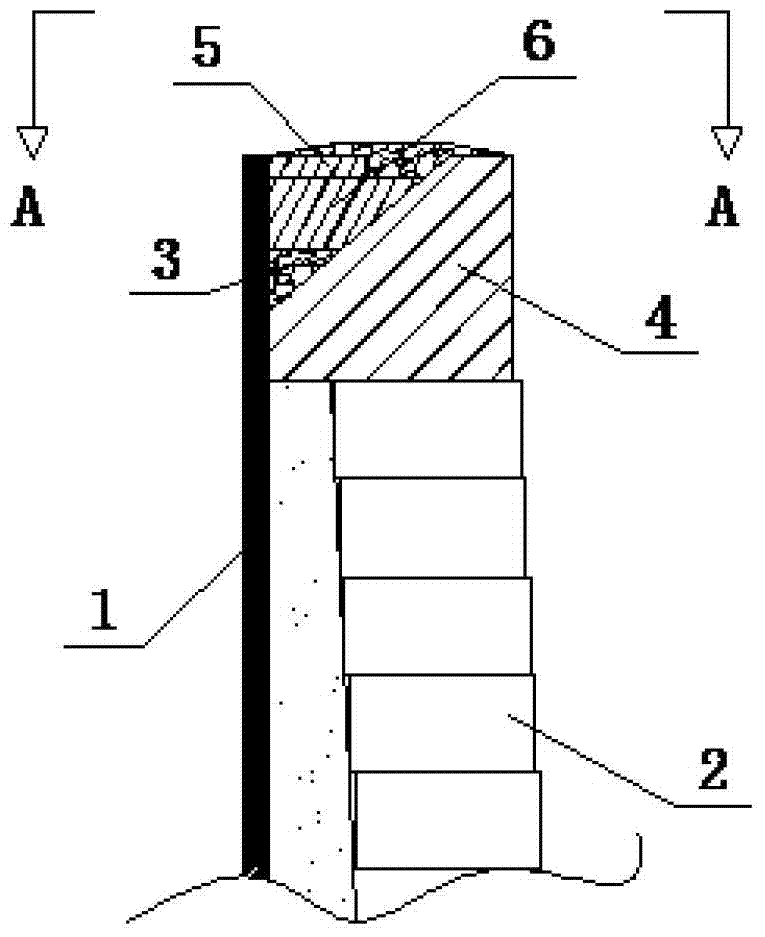

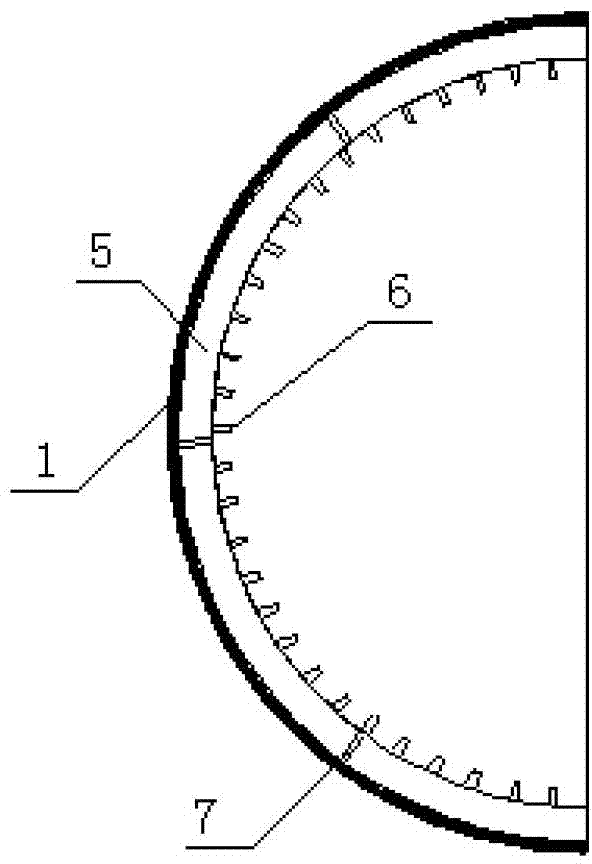

[0015] The vertical wedge-shaped metal pressing plate 6 is discontinuously welded along the circumferential direction of the mouth, increasing the distribution density of the vertical wedge-shaped metal pressing plate 6, and 70 are evenly arranged along the circumferential direction of the mouth; Direction continuous welding of the horizontal annular metal pressing plate 5, the horizontal annular metal pressing plate 5 is welded together with the cladding 1 and the vertical wedge-shaped metal pressing plate 6. There are 8 horizontal annular metal pressing plates 5, and there are annular pressing plate gaps 7 between each two; the wedge-shaped wrapping brick 4 and the vertical wedge-shaped metal pressing plate 6 are used to build masonry, and the vertical wedge-shaped metal pressing plate 6 and the wedge-shaped wrapping brick Fill the gap between 4 with ramming material 3.

[0016] The vertical wedge-shaped metal pressing plate 6 has a thickness of 30mm, a height of 130mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com