Grinding wheel position adjusting device of automatic band saw sawtooth processing device

An adjustment device and automatic processing technology, which is applied in the mechanical field, can solve the problem that the grinding wheel cannot be finely adjusted, and achieve the effects of increasing the scope of application, reducing the burden, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

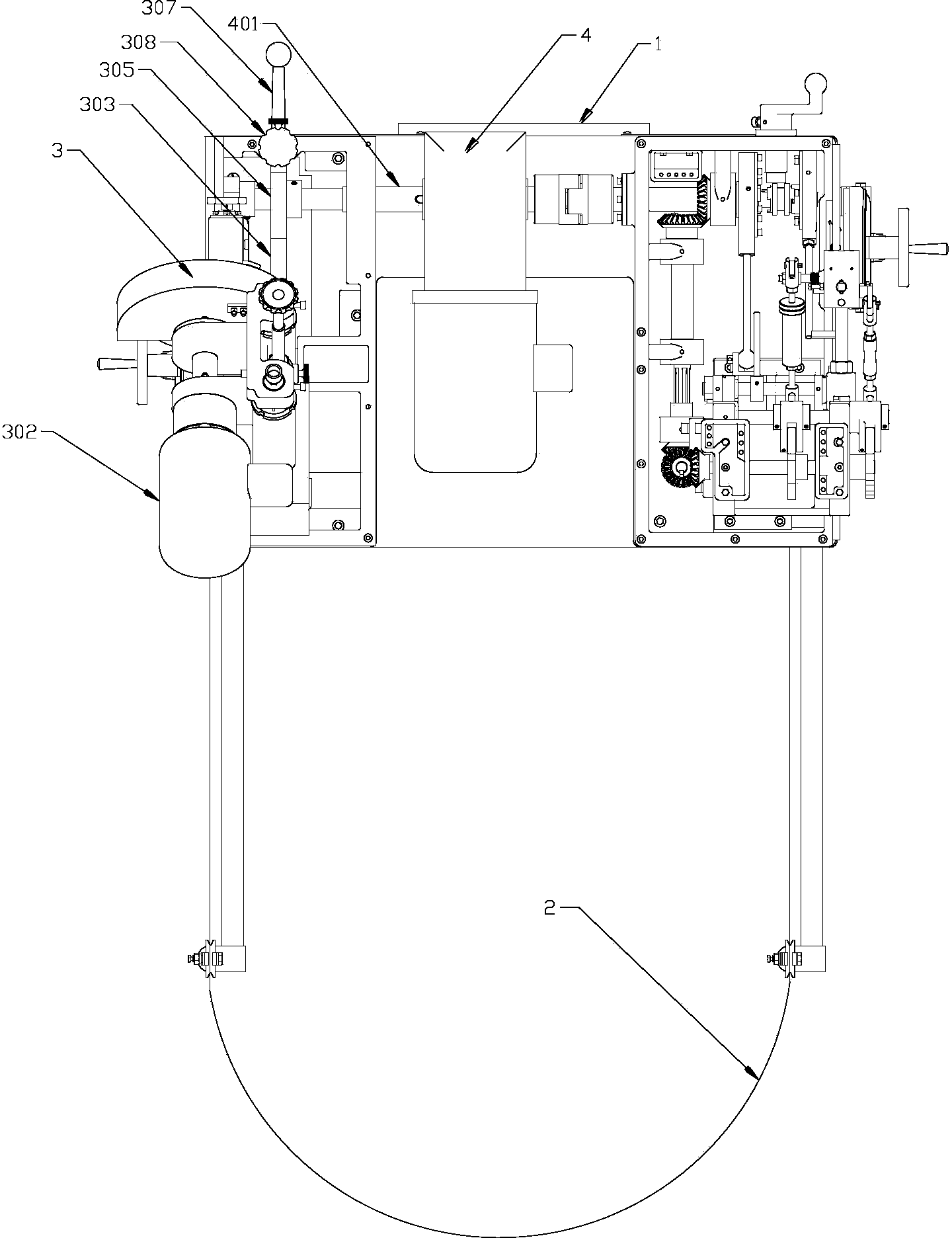

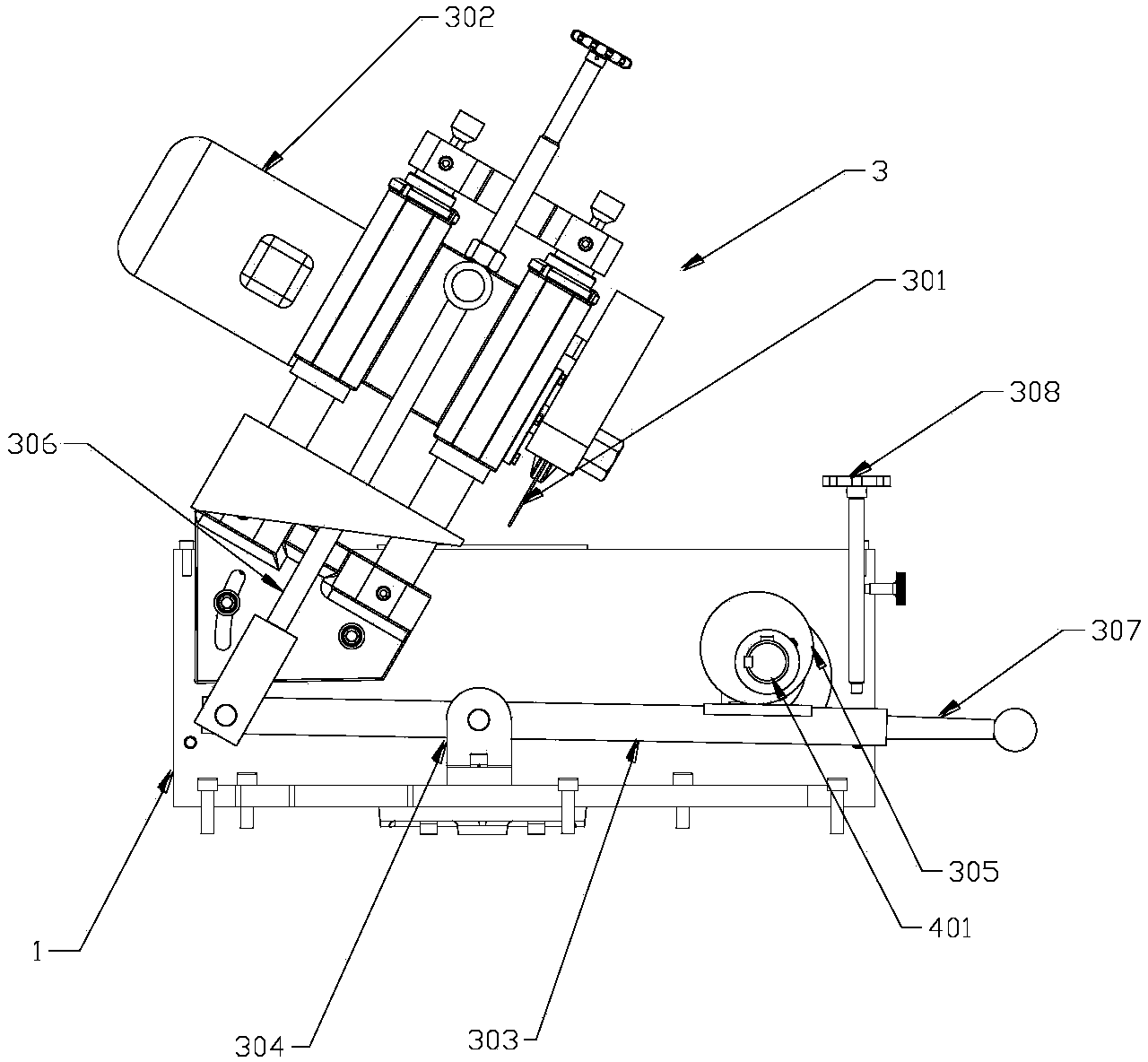

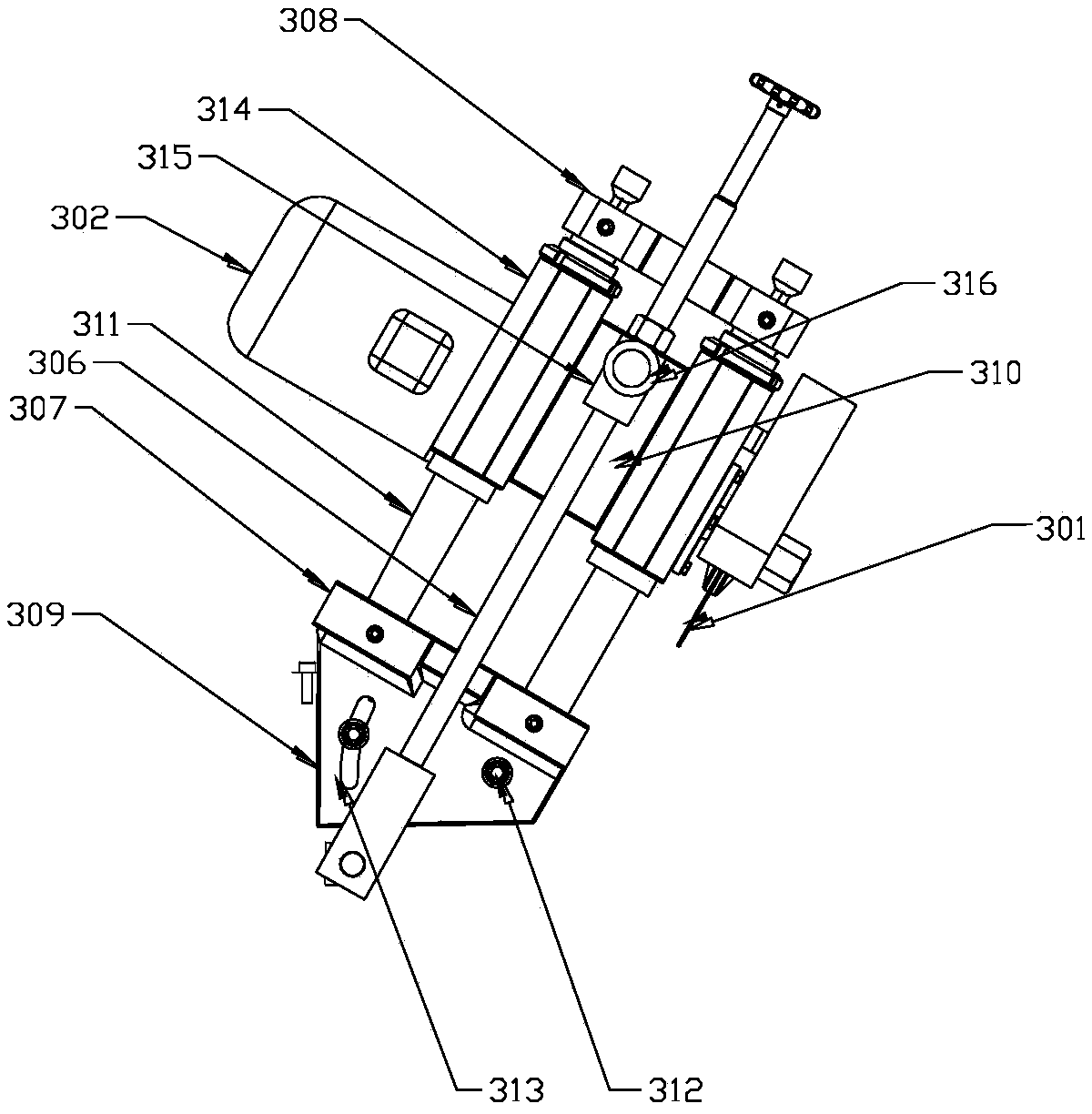

[0018] like figure 1 As shown, the grinding wheel position adjustment device of the band saw sawtooth automatic processing device of the present invention includes a grinding system 3 with a grinding wheel 301 and a grinding wheel drive motor 302, and a working frame 1 on which the grinding system 3 and the band saw 2 are installed. The drive motor 4 of the grinding system 3 is driven on the frame 1, and the grinding system 3 is installed on the working frame 1 through an adjustment seat for adjusting the angle and height of the grinding wheel.

[0019] In the present invention, the driving motor 4 drives the grinding system 3 to process the sawtooth 2, and the grinding system 3 adjusts the grinding angle and grinding height of the grinding wheel through the adjustment seat, so that the grinding system 3 can process any size or type of band saw, simplifying the process. It simplifies the operation of the grinding system, facilitates maintenance and improves the adaptability of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com