Welding equipment and technology of parts in closed cavity

A technology for welding parts and sealing cavities, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of no corresponding welding equipment and inability to weld, and achieve the problems of inability to weld, guarantee welding quality, and expand the field of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

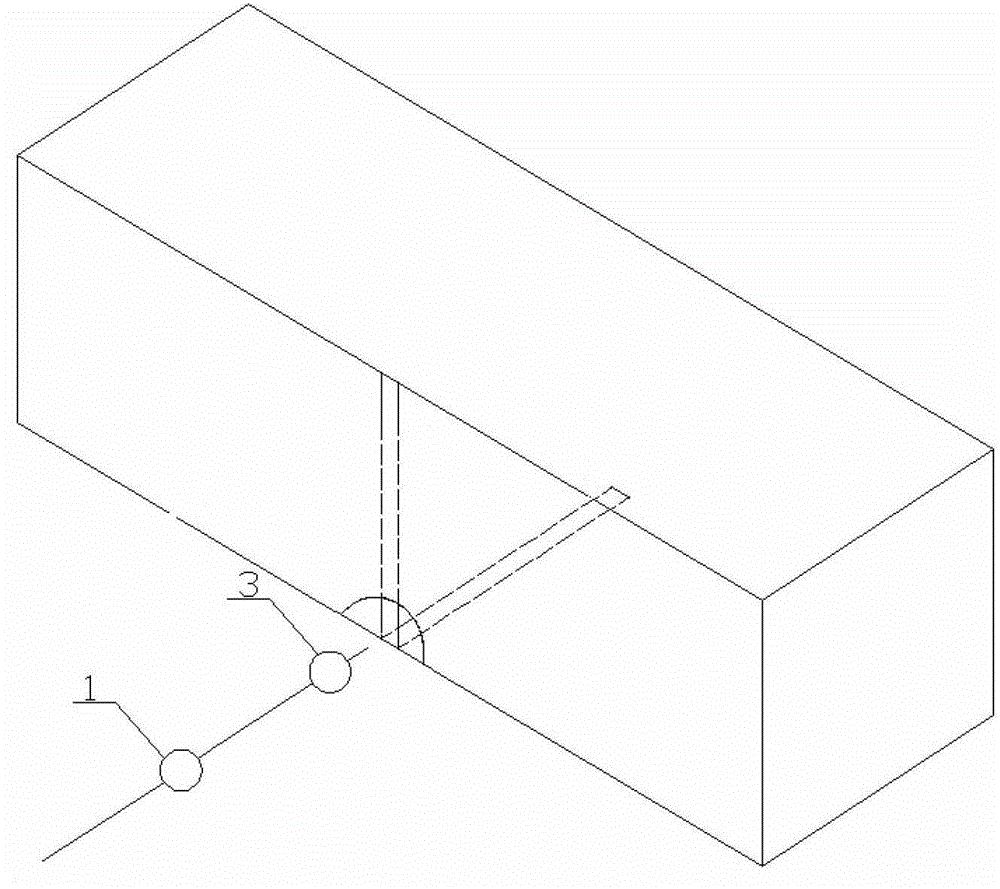

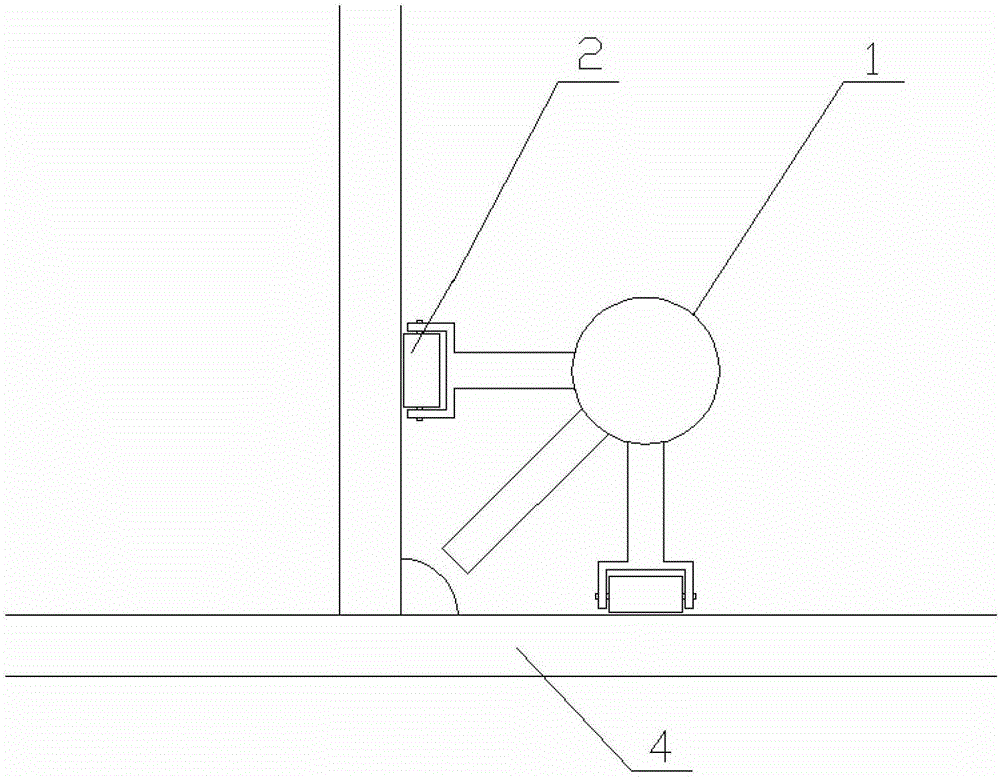

[0020] Welding equipment for parts in a closed cavity, including a welding torch 1, a two-dimensional magnetic positioning wheel 2, and a viewing mirror 3. The length of the welding torch 1 is 50%-150% of the length of the welding bead, and the two-dimensional magnetic positioning wheel 2 is set on the support of the welding torch 1. On the feet, the sight glass 3 is installed in the front of the welding torch 1.

[0021] The two-dimensional magnetic positioning wheel 2 moves on the steel plates 4 on both sides of the weld bead.

[0022] Peep mirror 3 is connected with display by wire.

[0023] The entering direction of the wire is opposite to that of the welding torch 1 .

[0024] The entry direction of the wire is equipped with a smoke absorbing device.

[0025] The welding torch 1 is a gas shielded welding machine.

Embodiment 2

[0027] The welding process of parts in a closed cavity includes the following steps:

[0028] a. There are 4 welding holes in the steel plate at both ends of the weld bead;

[0029] b. Install the cover plate and implement spot welding;

[0030] c. Flip the member so that the weld bead faces upward;

[0031] d. One end extends into the peep mirror 3 and connects with the welding torch 1 at the other end;

[0032] e. Move the sight glass 3 and the welding torch 1 to the starting welding position;

[0033] f. Carry out welding of internal parts; welding of internal parts shall be done in one time or separately from the center of the weld bead to both sides.

[0034] g. Welding hole sealing welding;

[0035] h. Cover welding.

[0036] The cross-section of the welding hole is larger than that of the welding torch and the sight glass, and the welding hole is located in a non-main structural part.

[0037] The welding quality is determined by the difference analysis method bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com