The stitching leak testing mechanism and process of the solar water heater tank liner rolling leak testing machine

A technology for a solar water heater and a leak detector, which is applied in the parts of solar collectors, solar collectors, solar thermal energy, etc., can solve the problems of low degree of automation and inability to automatically detect leakage and stitching of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

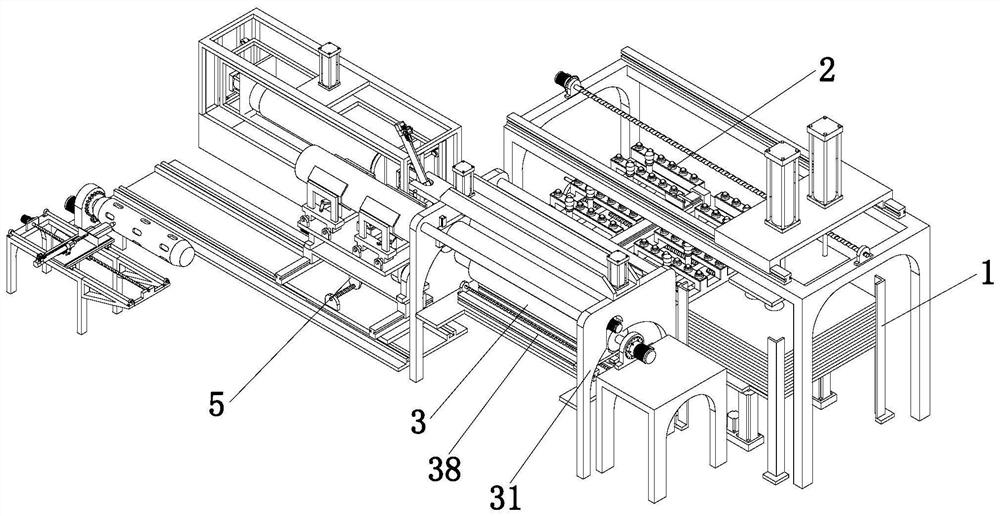

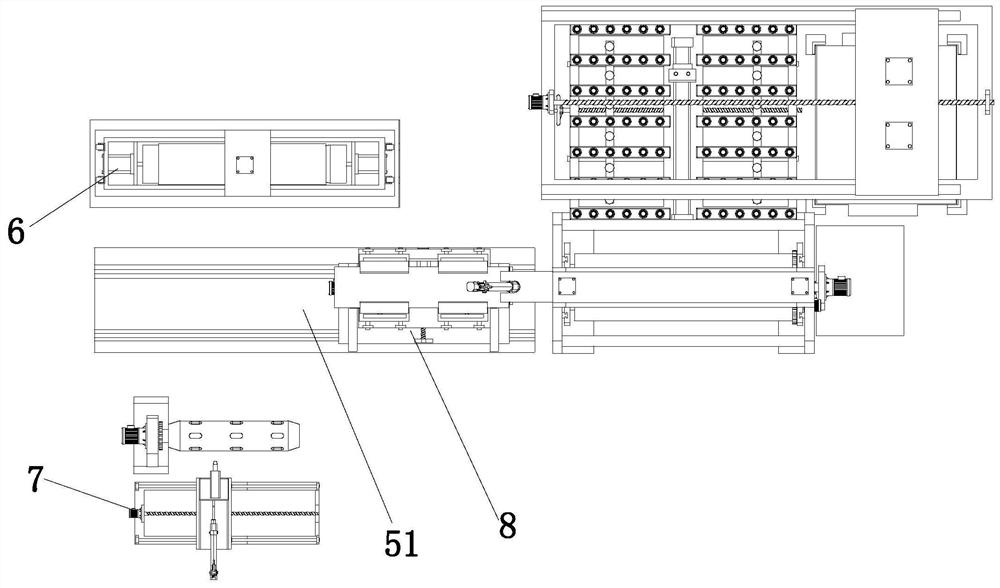

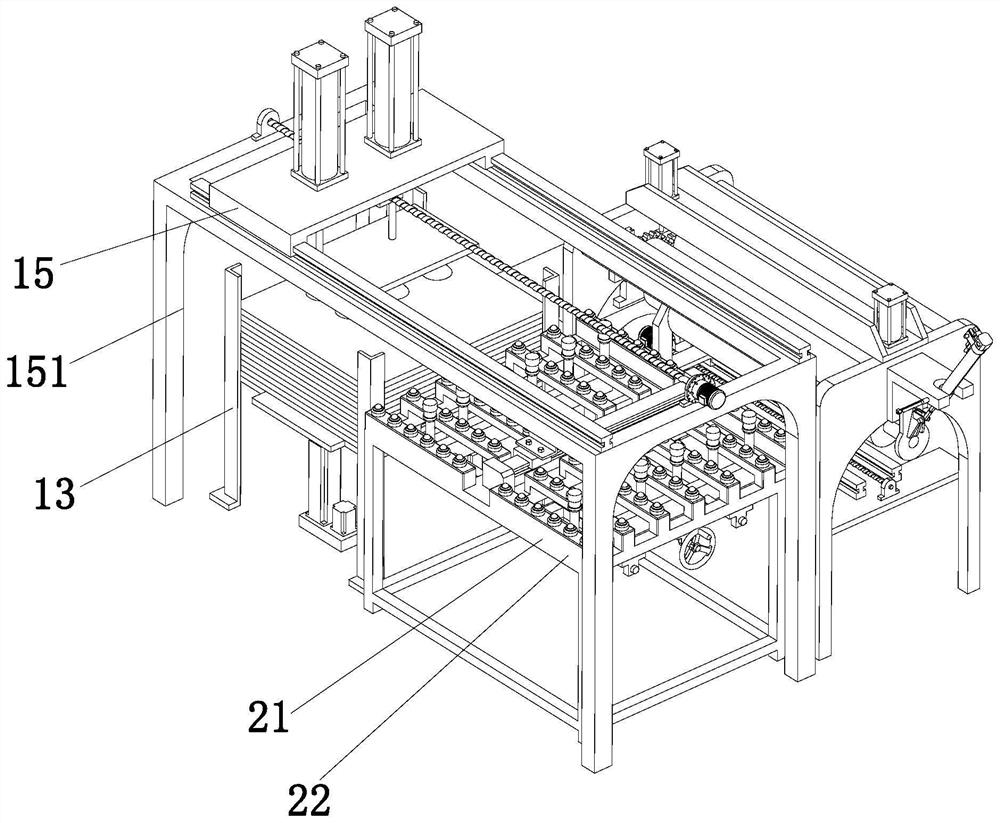

[0039] Combine below Figure 1 to Figure 14 As shown, the embodiment of the present invention provides a solar water heater water tank liner ball leak tester, including a sheet material feeding mechanism 1, a suture leak detection mechanism 5, a sheet material feeding mechanism 2 and an automatic rounding mechanism 3, the automatic rounding mechanism 3 It is arranged between the suture leakage detection mechanism 5 and the sheet material feeding mechanism 2, and the suture leakage detection mechanism 5 is arranged at the feeding end of the automatic rounding mechanism 3, and the sheet material feeding mechanism 1 is arranged on the side of the sheet material feeding mechanism 2 , the sheet material feeding mechanism 2 includes a carrier frame 21, a limit assembly on both sides 4 and an automatic pusher assembly 26, the limit assembly on both sides 4 is arranged on the carrier frame 21, and the automatic pusher assembly 26 is arranged on The middle section of the top of the car...

Embodiment 2

[0056] The stitching leak detection mechanism process of the solar water heater water tank liner rolling leak detection machine described in embodiment 1 comprises the following steps:

[0057] Workers manually stack the stainless steel plates between the four limit plates 868, and the stainless steel plates can be sequentially moved to the plate feeding mechanism 2 through the plate feeding mechanism 1, so that the plate feeding mechanism 2 automatically pushes the stainless steel plates to the automatic rounding Mechanism 3, specifically, the first screw slide 153 works to move the lifting cylinder 154 to the top of the stacked plates, and the lifting cylinder 154 works to move the lifting plate 152 vertically downward, so that the lifting plate 152 can Drive the suction cup to move vertically downwards, so that the suction cup can absorb the uppermost plate, and the lifting cylinder 154 can work again to make the uppermost plate be taken out, so that the plate can break away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com