AABR (Anaerobic Baffled Reactor)-compound type MBR (Membrane Biological Reactor) integrated device and method for treating organic wastewater

An organic wastewater, composite technology, applied in water/sludge/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Membrane fouling, reducing energy consumption, optimizing the effect of aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

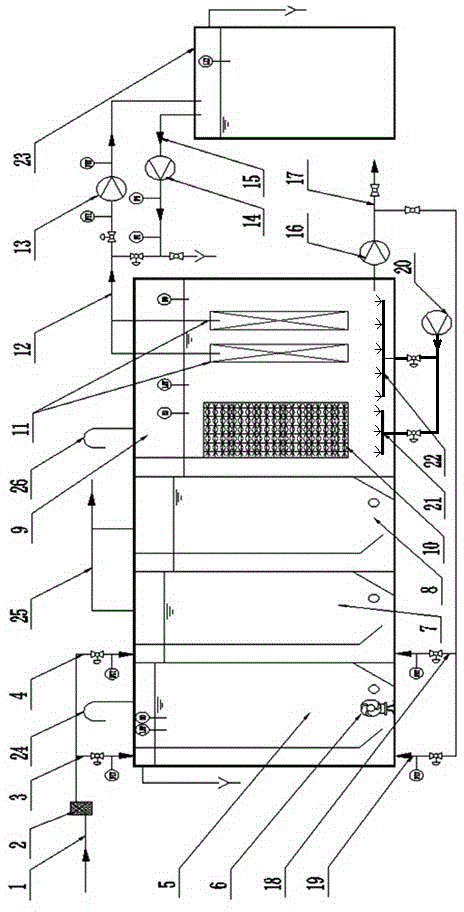

Image

Examples

example 1

[0039] Example 1. The amount of treated water: 200m of a biopharmaceutical wastewater 3 / d.

[0040] Influent water quality: COD: 2000~2700mg / L, BOD: 500~700mg / L, NH 3 -N: 130-160 mg / L, TP: 4-6 mg / L, SS: ≤200 mg / L.

[0041] Design parameters: The AABR reaction tank is divided into three compartments, the first compartment is an anoxic section, and the second and third compartments are anaerobic sections. The volume of each compartment is the same, the width ratio of the downflow chamber and the upflow chamber is 1:4, and the angle of the baffle is 45°. The residence time of the anoxic section is 6h, the residence time of the anaerobic section is 12h, and the residence time of the composite MBR reaction tank is 16h.

[0042] Equipment selection: submersible mixer power 0.3KW, MBR membrane module adopts curtain type hollow fiber membrane module, model FP-AⅣ, elastic packing specification: φ200×1500, blower power: 3kw, sludge / mixed liquid return pump power 2.2kw, The power of...

example 2

[0046] Example 2, the amount of treated water: 1000m of sugar beet wastewater 3 / d.

[0047] Influent water quality: COD: 5000~6000mg / L, BOD: 2000~2800mg / L, NH 3 -N: ≤50mg / L, SO 4 2- : 350~600mg / L, SS: 1000~4000mg / L.

[0048] Design parameters: The AABR reaction tank is divided into three compartments, the first compartment is an anoxic section, and the second and third compartments are anaerobic sections. The volume of each compartment is the same, the width ratio of the downflow chamber and the upflow chamber is 1:4, and the angle of the baffle is 45°. The residence time of the anoxic section is 6h, the residence time of the anaerobic section is 24h, and the residence time of the composite MBR reaction tank is 20h.

[0049] Equipment selection: submersible mixer power 1.5KW, MBR membrane module adopts curtain type hollow fiber membrane module, model FP-AⅣ, elastic packing specification: φ200×1500, blower power: 15kw, sludge / mixed liquid return pump power 4kw, output Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com