Two-phase bioretention tank with simultaneous nitrogen and phosphorus removal functions and its construction method

A technology for simultaneous denitrification and phosphorus removal, and biological retention ponds, which are applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., and can solve problems such as rainwater resource loss and building roof runoff pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: the screening of filler

[0069] Selection of suitable filler is crucial for phosphorus removal. The amount of phosphorus contained in the filler itself has a great influence on the migration and transformation of phosphorus in the bioretention system. Fillers with a high phosphorus content index have a small absorption capacity for phosphorus. When the phosphorus content index is close to saturation, it will not only affect the phosphorus absorption capacity of the filler, but also seriously increase the phosphorus concentration in the effluent. Therefore, fillers with moderate phosphorus content should be selected, so as to ensure the normal growth of plants and receive better phosphorus removal effect.

[0070] The fillers used in this research are zeolite, quartz sand, medical stone, ceramsite, anthracite, aluminum sludge, river sand, fruit shell, activated carbon, fly ash, slag, etc. For desorption experiments, according to the experimental results,...

Embodiment 2

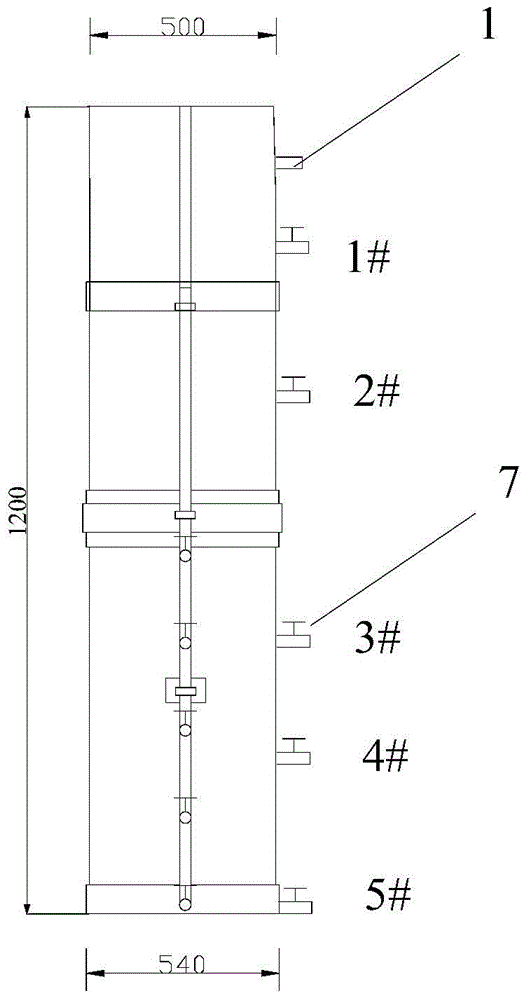

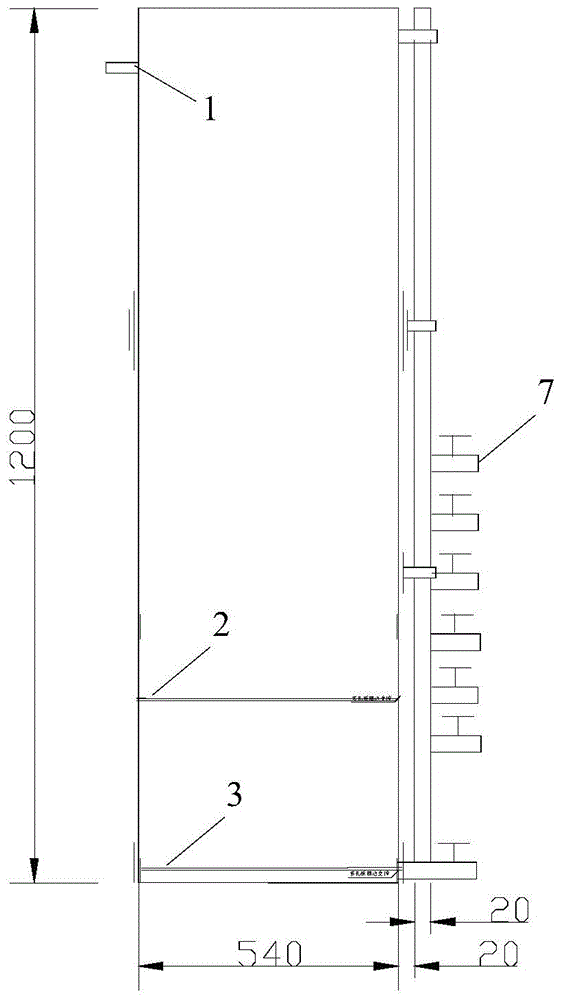

[0083] Example 2: Determining the layout of the two-phase area

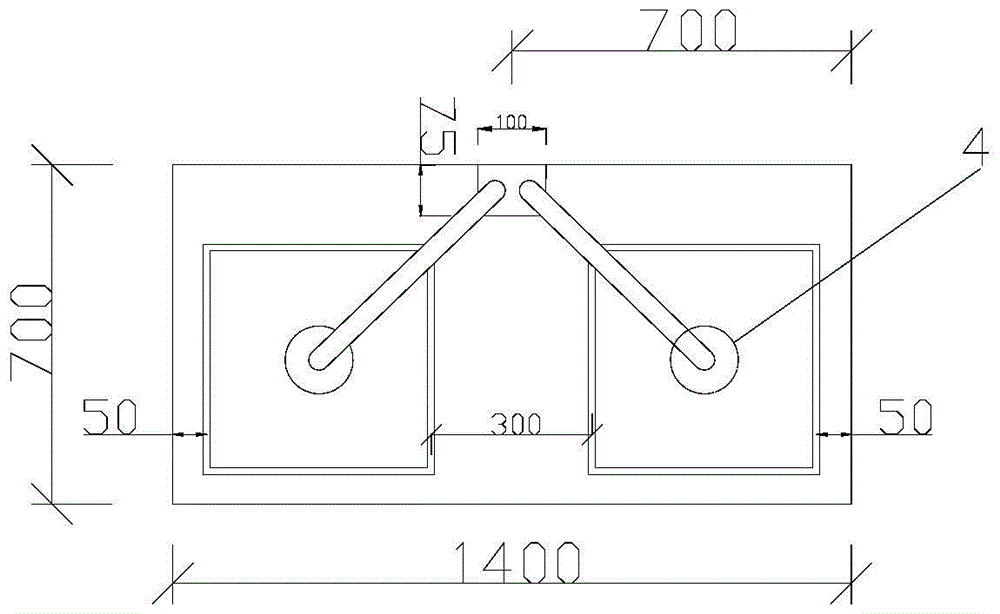

[0084] The experimental device used in this example is as figure 1 -5. The device is an experimental model of biological retention enhanced denitrification and phosphorus removal; device length × width × height = 500mm × 500mm × 1200mm; from top to bottom, it is planting soil layer, filling layer and gravel layer. The container of the device is welded and formed by plexiglass, and the inner wall of the device is roughened. A water outlet 7 is arranged on the wall 8 of the test container. In the device, an upper perforated plate 2 is installed between the packing layer and the gravel layer and a geotextile is laid. The cloth prevents the plant soil from spilling down into the gravel layer. The bottom of the device is provided with an upflow tube connected to the nozzle 4, and a flow regulating valve 5 is arranged on the upflow tube; the upflow tube is a DN20 / UPVC bonding tube, and the upflow tube is fixed vert...

Embodiment 3

[0095] A two-phase bioretention tank, from top to bottom are planting soil layer (thickness 200mm), packing layer and gravel layer, the packing layer is composed of zeolite + quartz sand + aluminum sludge + river sand in a volume ratio of 3:1:1 : 5 components, the thickness of the packing layer is 600mm, the thickness of the gravel layer is 300mm, and a perforated collection pipe with a diameter of 100mm is buried at the bottom of the gravel layer. The bottom of the packing layer is at a height of 5cm upwards. The principle of the two-phase bioretention tank constructed by the present invention to treat runoff is shown in Figure 6 .

[0096] The water quality used for testing includes indicators such as total phosphorus, ammonia nitrogen, nitrate nitrogen, and total nitrogen. Water treatment experiment results: the effect of two-phase bioretention tank on TP, NH 4 -N, NO 3 The removal rates of -N and TN are 88.22%, 86.67%, 60.80% and 68.35%, respectively, and the effect o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com