Integrated treatment device and method for low concentration sewage

A treatment device and low-concentration technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of sludge loss and low treatment efficiency, and prevent sludge The effect of churn, simple operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

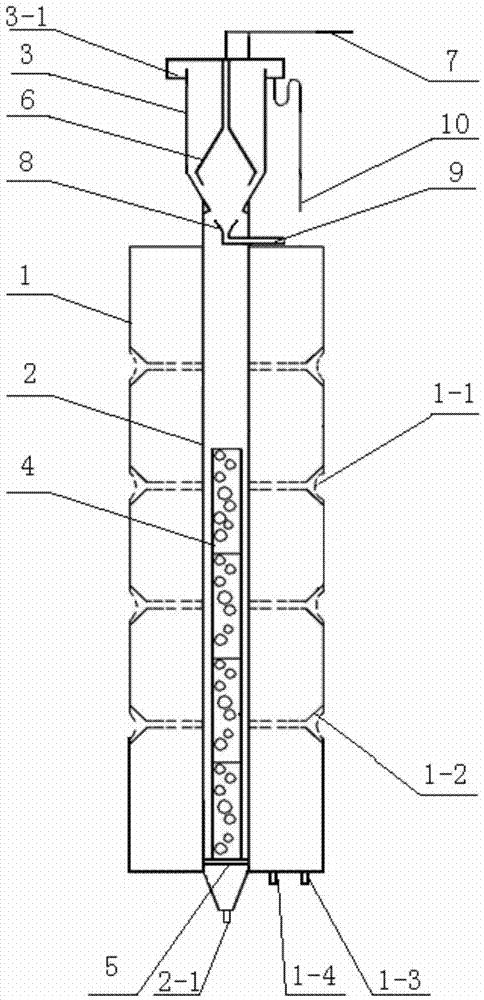

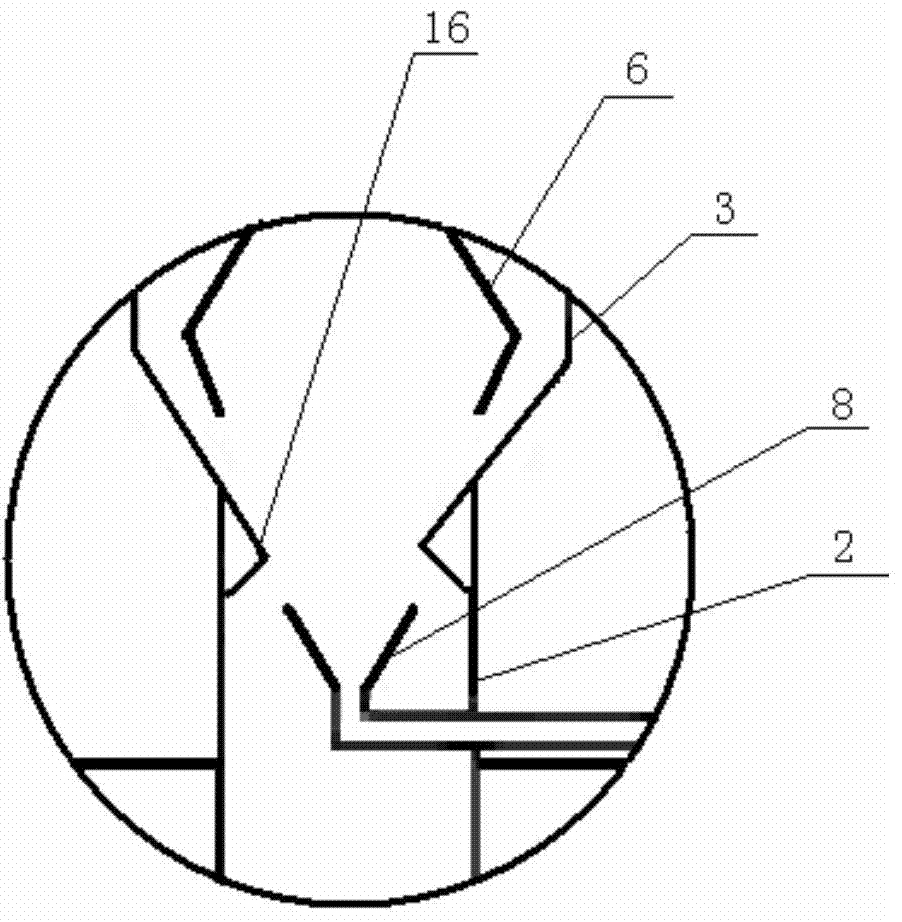

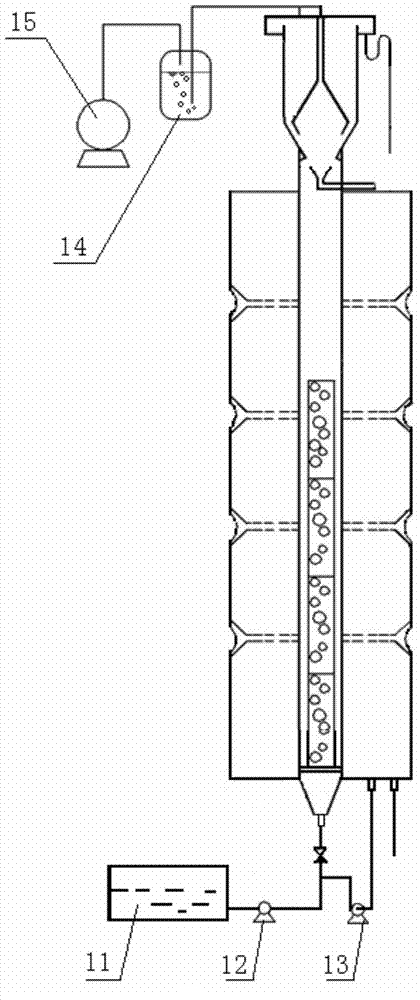

[0021] Specific implementation mode one: (see figure 1 ) The integrated treatment device for low-concentration sewage in this embodiment includes a bamboo-shaped aerobic outer cylinder 1, an anaerobic inner cylinder 2, a three-phase separation cylinder 3, a bamboo-shaped hollow cylinder 4, a water distributor 5, and an air collecting hood 6. Air pipe 7, mud discharge bucket 8, mud discharge pipe 9, S-shaped connecting pipe 10;

[0022] The anaerobic inner cylinder 2 is set in the bamboo-shaped aerobic outer cylinder 1, and the bottom of the three-phase separation cylinder 3 is connected to the top of the anaerobic inner cylinder 2;

[0023] The bamboo-shaped aerobic outer cylinder 1 is composed of several sections. The bamboo-shaped aerobic outer cylinder at both ends is filled with filler A, and the bamboo-shaped aerobic outer cylinder in the middle is filled with a mixture of filler A and coagulant. Ventilation holes 1-1 are set on the outer wall of the bamboo-shaped aerobi...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the filler A in the bamboo-jointed tubes at both ends of the bamboo-shaped aerobic outer cylinder 1 is a shell. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that in the bamboo-shaped aerobic outer cylinder 1 in the middle, the coagulant is polyaluminum chloride or aluminum sulfate. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com