Film bioreactor and sewage treatment process

A membrane bioreactor, sewage treatment technology, applied in water/sewage treatment, sustainable biological treatment, water/sewage treatment equipment, etc., can solve problems such as poor denitrification and phosphorus removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

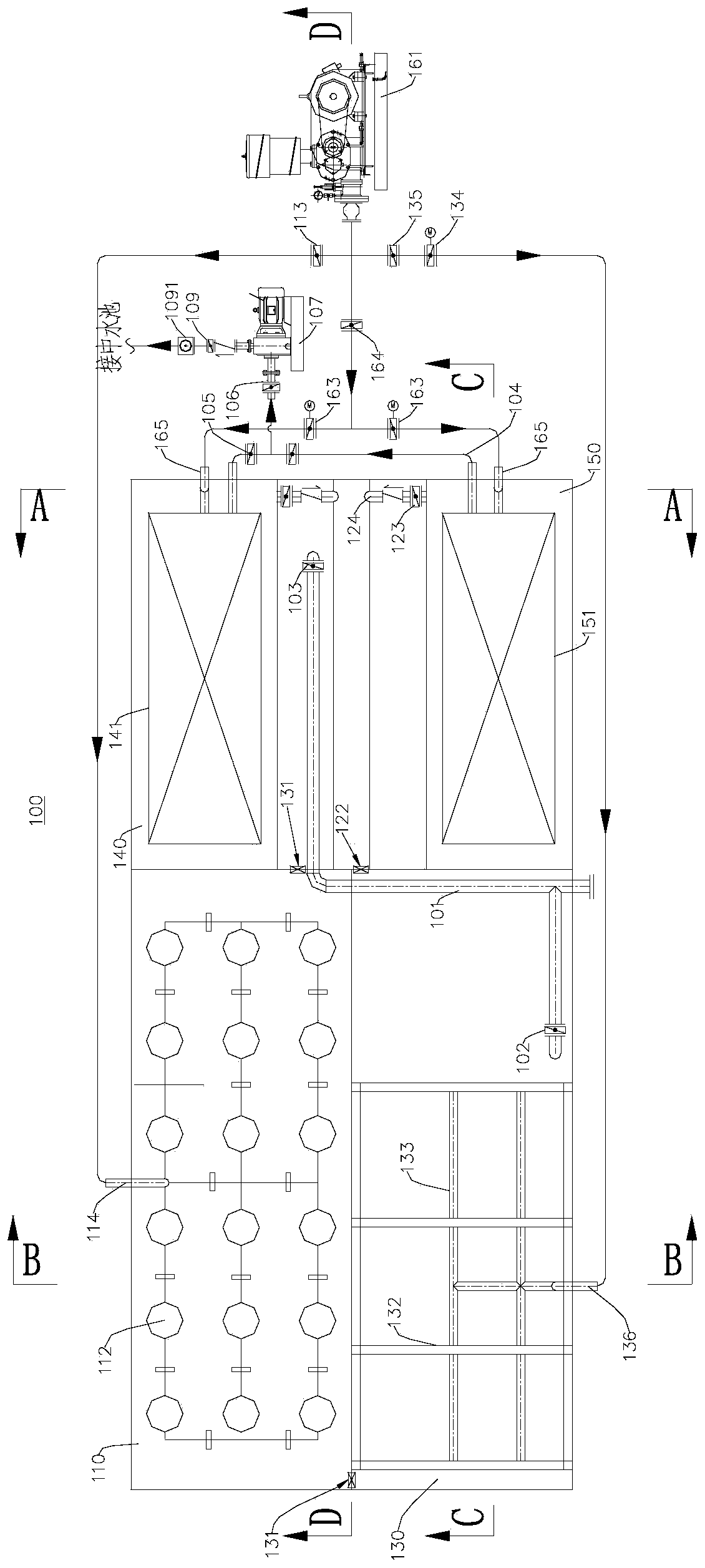

[0045] figure 1 A schematic structural diagram of the membrane bioreactor 100 provided by the embodiment of the present application is shown, please refer to figure 1 . This embodiment provides a membrane bioreactor 100, which is mainly used for sewage treatment.

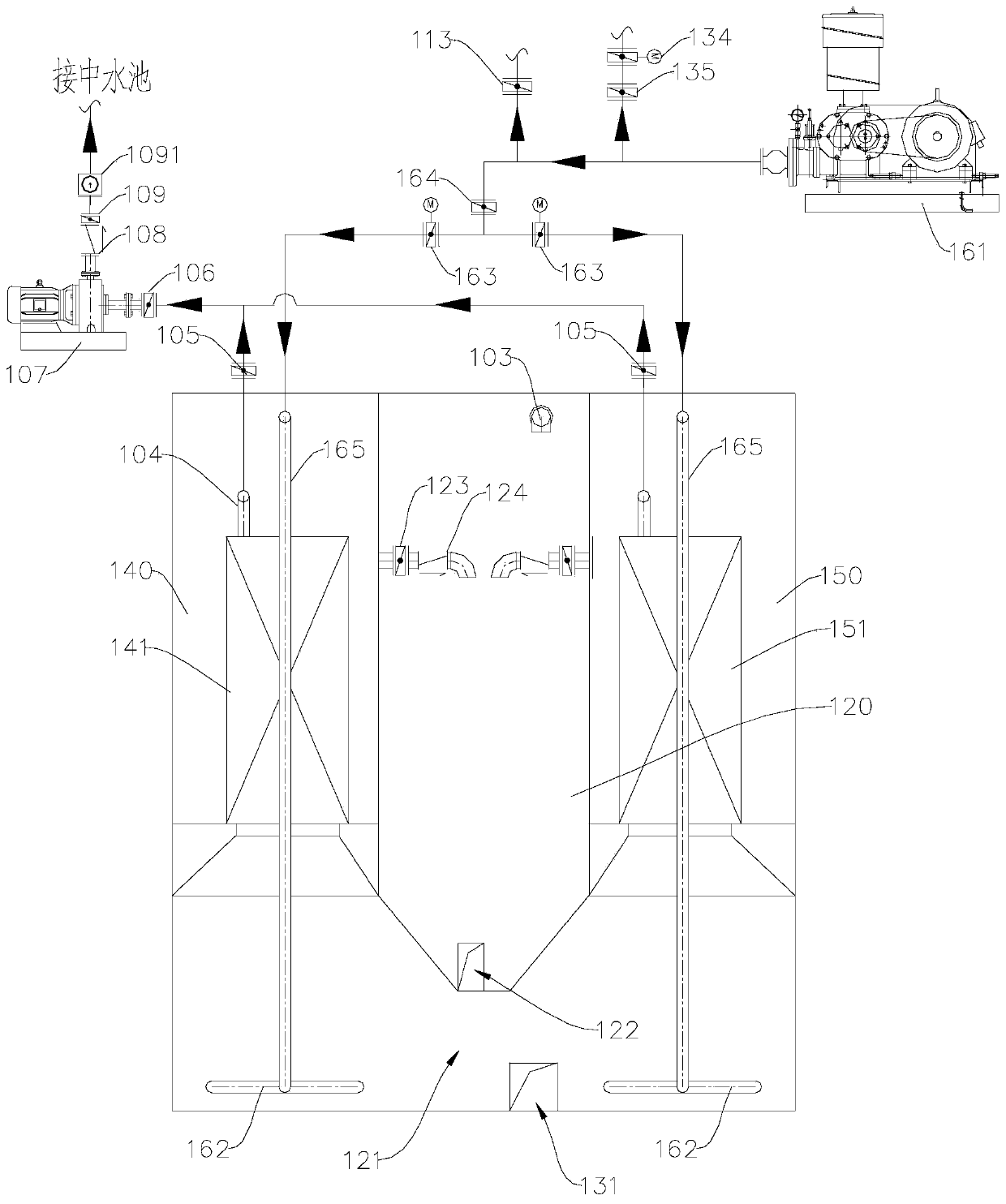

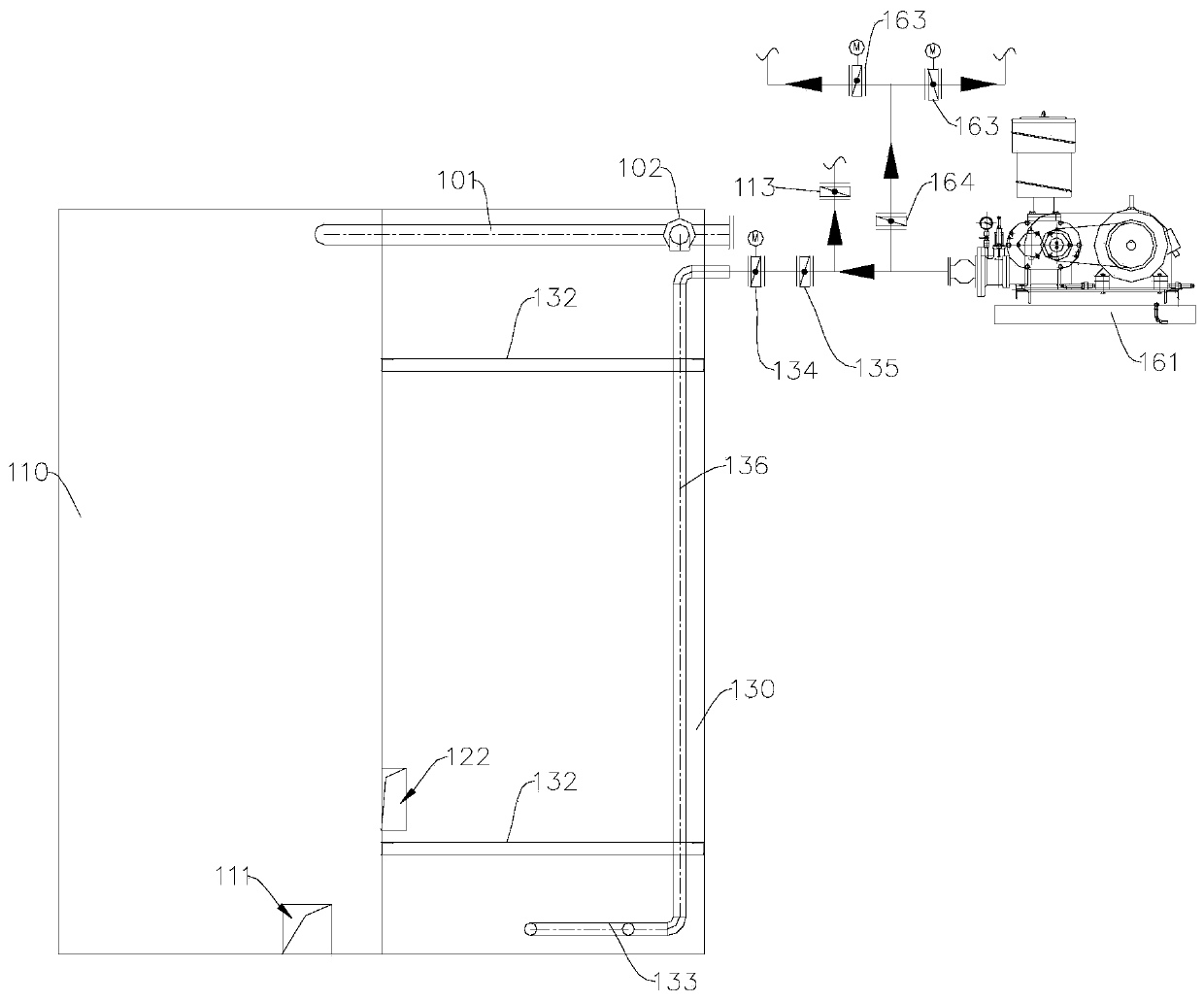

[0046] The membrane bioreactor 100 includes an aerobic tank 110 , an anoxic tank 120 , an anaerobic tank 130 and two membrane tanks, and the two membrane tanks are respectively named as a first membrane tank 140 and a second membrane tank 150 .

[0047] The aerobic pool 110 and the anoxic pool 120 are separated by a partition, the anaerobic pool 130 and the aerobic pool 110 are separated by a partition, and the anaerobic pool 130 and the anoxic pool 120 are separated by a partition . The first film pool 140 and the second film pool 150 are arranged on both sides of the anoxic pool 120, and the first film pool 140 and the second film pool 150 are separated from the anaerobic pool 130 and the aerobic pool 110 with ...

Embodiment 2

[0106] This embodiment provides a sewage treatment process, using the membrane bioreactor 100 provided in Example 1 for sewage treatment.

[0107] see Figure 1-Figure 5 and Example 1.

[0108] The process of sewage treatment mainly includes:

[0109] The sewage is transported through the anaerobic pool 130 and the anoxic pool 120, and then enters the first membrane pool 140 or the second membrane pool 150 through the aerobic pool 110, and is output after being purified. In the process of sewage treatment, the sludge in the membrane bioreactor 100 is circulated as follows:

[0110] Aerobic pool 110——Aerobic pool Membrane pool sludge channel 111—Membrane pool—Sludge return regulating valve 123—Check valve 124—Anoxic pool 120—Anoxic anaerobic sludge channel 122— —anaerobic pool 130 —anaerobic-aerobic sludge channel 131 —aerobic pool 110.

[0111]Further, in this embodiment, the suction pump 107 that sucks the purified water into the membrane tank operates intermittently. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com