Method for reasonably optimizing and distributing carbon source in treatment of refractory wastewater

An optimized distribution and refractory technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve poor treatment effect, insufficient impact capacity of industrial wastewater, high treatment cost, etc. problems, to achieve the effect of solving carbon source shortage, improving biodegradability, and improving nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

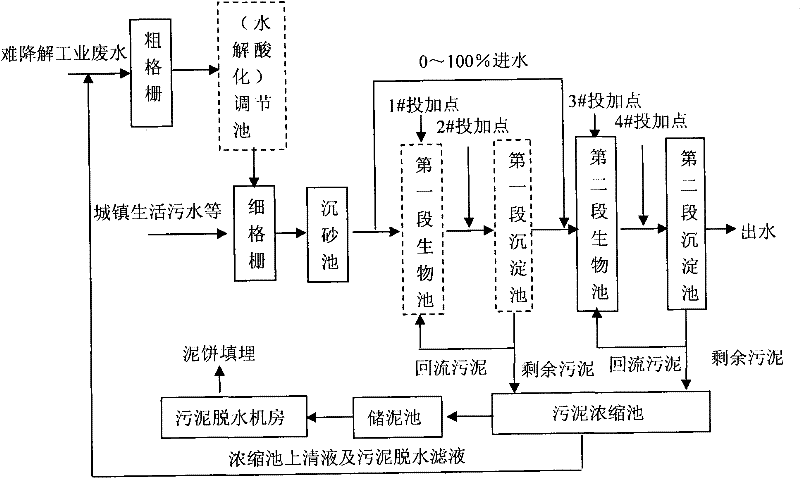

[0016] Example 1: High-concentration refractory industrial wastewater is first hydrolyzed and acidified through the coarse screen and the hydrolytic acidification regulating tank, and then the effluent is combined with urban domestic sewage. After the mixed sewage passes through the fine screen and the sedimentation tank, 90% of the mixed sewage enters a section of biological The effluent from the first biological pool enters the first sedimentation tank, the effluent from the first sedimentation tank and the other 10% mixed sewage enter the second biological pool, the effluent from the second biological pool enters the second sedimentation tank, and the effluent from the second sedimentation tank is discharged. 80% of the sludge in the first-stage sedimentation tank and the second-stage sedimentation tank is returned to the respective biological pools. The hydraulic retention time of a biological pool is controlled at 0.5-3 hours, the sludge age is controlled at 1-5 days, the ...

Embodiment 2

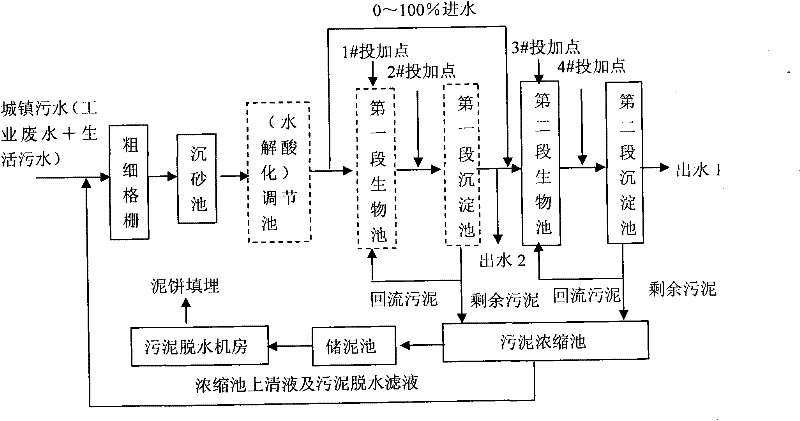

[0017] Example 2: High-concentration refractory industrial wastewater is first hydrolyzed and acidified through coarse screens and hydrolytic acidification adjustment tanks, and then the effluent is combined with urban domestic sewage. After the mixed sewage passes through fine screens and sedimentation tanks, 90% of the mixed sewage enters a section of biological The effluent from the first biological pool enters the first sedimentation tank, the effluent from the first sedimentation tank and the other 10% mixed sewage enter the second biological pool, the effluent from the second biological pool enters the second sedimentation tank, and the effluent from the second sedimentation tank is discharged. 80-100% of the sludge in the first-stage sedimentation tank and the second-stage sedimentation tank is returned to the respective biological pools. The coagulant is added to the outlet of the second-stage biological pool to reduce the organic load and realize chemical phosphorus re...

Embodiment 3

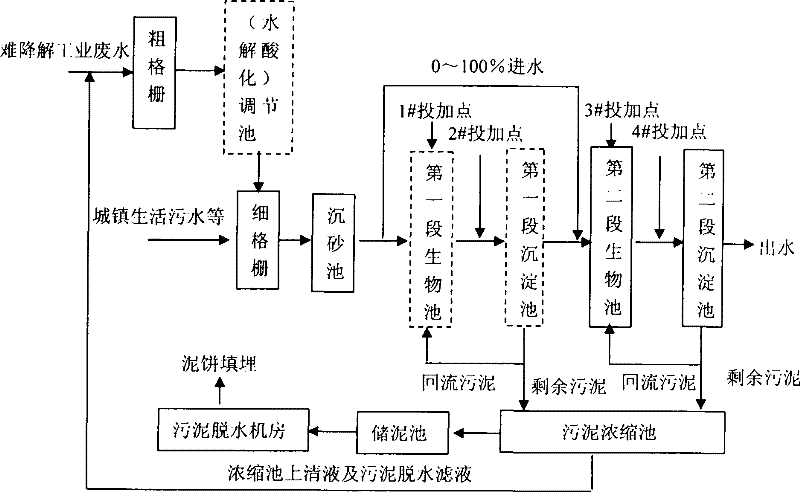

[0018] Example 3: High-concentration refractory industrial wastewater is first hydrolyzed and acidified through coarse screens and hydrolytic acidification adjustment tanks, and then the effluent is combined with urban domestic sewage. After the mixed sewage passes through fine screens and sedimentation tanks, about 50% of the mixed sewage enters the first stage Biological pool, the effluent from the first biological pool enters the first sedimentation tank, the effluent from the first sedimentation tank and the other 50% mixed sewage enter the second biological pool, the effluent from the second biological pool enters the second sedimentation tank, and the effluent from the second sedimentation tank is discharged. 100% of the sludge in the first-stage sedimentation tank and the second-stage sedimentation tank is returned to the aeration tank. Coagulant is added to remove phosphorus at the effluent of the second-stage biological pool. The hydraulic retention time of a biologic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com