Modifier for silicon-aluminum alloy melt and method for preparing silicon-aluminum alloy using the modifier

A silicon-aluminum alloy and modifying agent technology, applied in the field of alloys, can solve the problems of inability to modify the silicon-aluminum alloy, the size of the ingot is small, and cannot be applied in engineering, and achieves the effect of fine alloy structure, improved alloy structure, and good metamorphic function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 40kg of pure silicon and 60kg of pure aluminum respectively, put the pure aluminum into the bottom of the intermediate frequency furnace, put silicon into the top, and heat with electricity until the aluminum and silicon are all melted into a melt, and the temperature of the melt is raised to 1100°C, and fully stirred , turn off the power and let it cool down to 1000°C, add 0.6% modifier by weight (modifier content and weight ratio are Na 2 SO 4 8%, NaCl8%, K 2 ZrF 6 16%; Na 3 PO 4 68%). After the end of metamorphism and standing for 10 minutes, use C 2 Cl 6 Degassing and refining the silicon-aluminum melt with the Hongguang refining agent HGJ-1A purchased on the market, and deslagging off the melt after the end. Heat the melt to 1150°C, pour it into the diversion tank for spray deposition process, the atomization pressure is 0.6-0.8MPa, the atomization gas is nitrogen, the deposition distance is 680-710mm, and the melt is sprayed into a diameter of 220mm. ...

Embodiment 2

[0037] Weigh 50kg of pure silicon and 50kg of pure aluminum respectively, and complete the melt treatment according to the steps of Example 1, wherein the temperature of adding the modifier is 1100°C, (the content of the modifier is 0.6%, and its components and weight ratio are, Na 2 SO 4 10%, NaCl10%, K 2 ZrF 6 20%;Na 3 PO 4 60%). The melt temperature during the spray deposition process is 1200°C, and the other parameters remain unchanged.

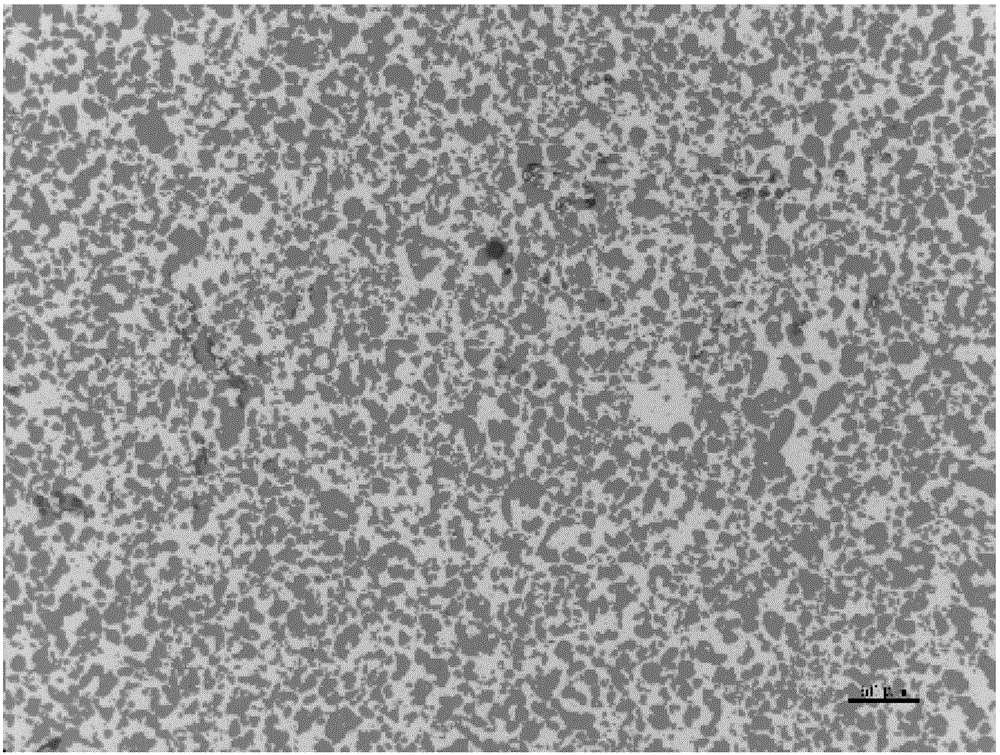

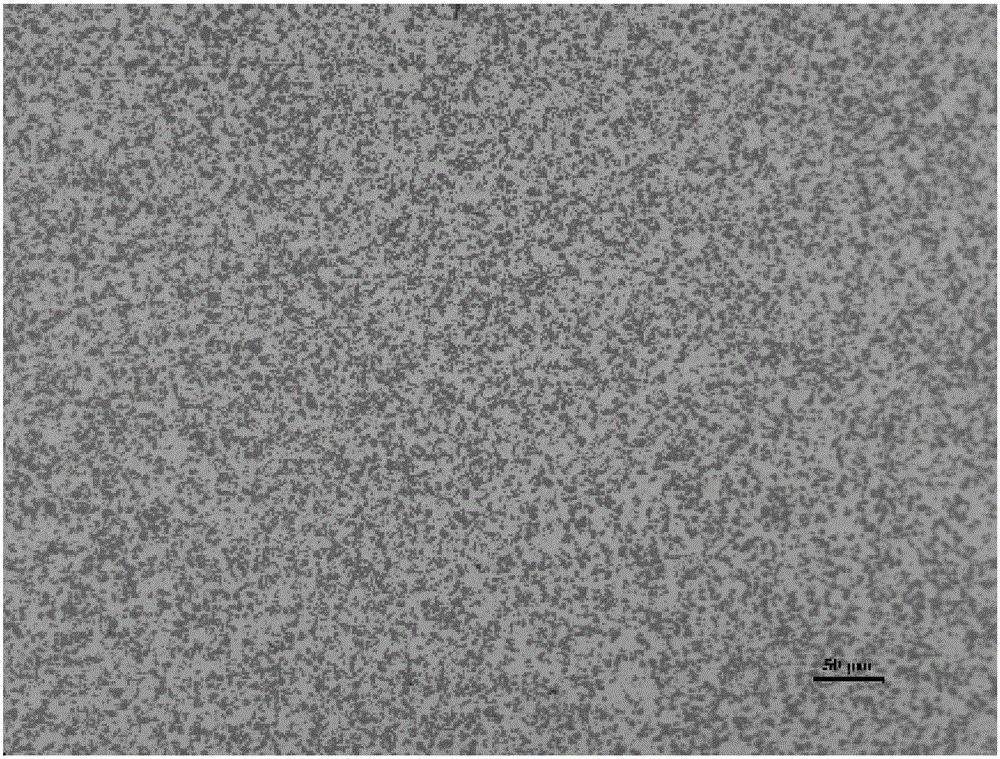

[0038] The microstructures of spray-deposited 50Si50Al alloy treated with modifier and conventional modifier (Al-P alloy) after hot isostatic pressing are as follows: image 3 with Figure 4 shown. It can be seen from the figure that the silicon-aluminum alloy modified by conventional modifiers has a very uneven primary silicon structure, the smallest is 5um, and the largest is 45um, and the shape of the primary silicon is very irregular, with sharp edges and corners. The primary silicon with this shape tends to generate microcra...

Embodiment 3

[0041] Weigh 70kg of pure silicon and 30kg of pure aluminum respectively, and complete the melt treatment according to the steps of Example 1, wherein the temperature of adding the modifier is 1300°C, (the content of the modifier is 0.6%, and its components and weight ratio are Na 2 SO 4 12%, NaCl12%, K 2 ZrF 6 24%; Na 3 PO 4 52%) for the spray deposition process, the melt temperature was 1450°C, and the other parameters remained unchanged.

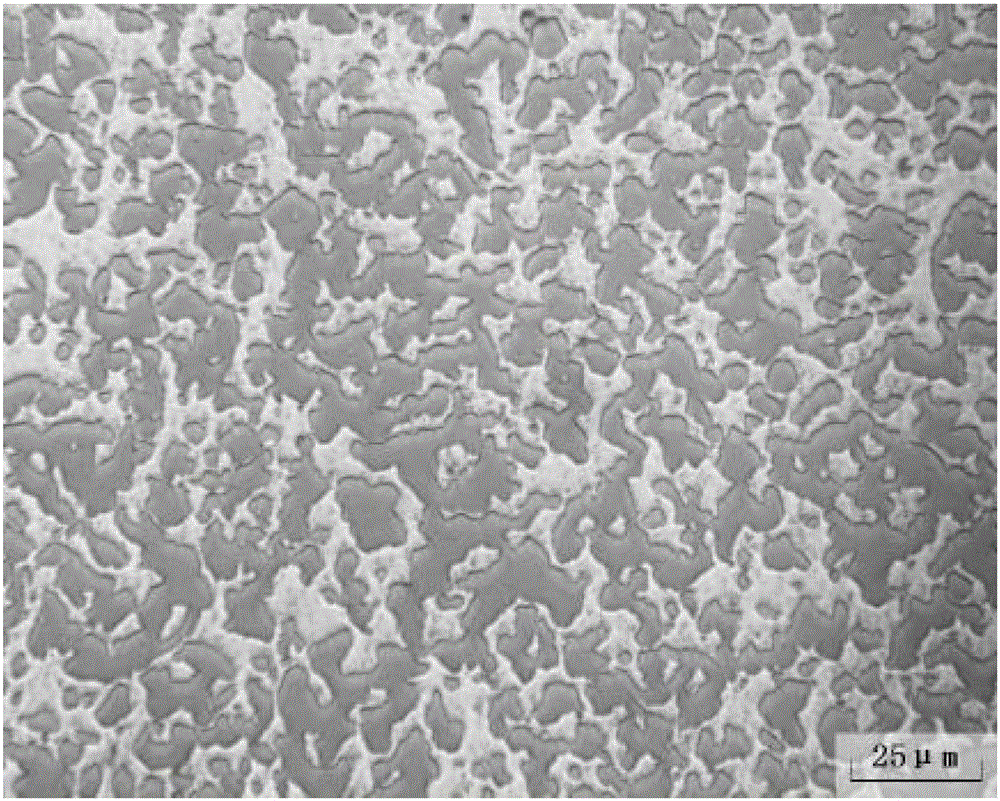

[0042] Spray-deposited 70Si30Al alloy treated with modifiers after hot isostatic pressing, such as Figure 5 shown. It can be seen from the figure that after the modification and hot isostatic pressing of the 70Si30Al alloy, there are no micropores in the structure, and the structure is relatively uniform, round, and the amount of primary silicon is large.

[0043] The physical properties of the 70Si30Al alloy after hot isostatic pressing with a modifier were tested. The test results show that the thermal expansion coefficient of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com