Preparation method of submicron antibacterial silver particles on magnesium alloy surface

An antibacterial silver and sub-micron technology, applied in the field of metal surface treatment, can solve the problems of no antibacterial function of the modified layer, weak corrosion resistance of magnesium alloys, poor corrosion resistance of magnesium alloys, etc., and achieve the effect of reducing the probability of local inflammatory reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A method for preparing submicron antibacterial silver particles on the surface of a magnesium alloy, comprising a degreasing step, a water washing step, a step of preparing submicron antibacterial silver particles, a water washing step, an alcohol washing step and a drying step, wherein the degreasing step, the water washing step, the water washing step Step, alcohol washing step and drying step all adopt the conventional method, and the main inventive point of the present invention is to improve the step of preparing submicron antibacterial silver particles. Therefore, the present embodiment aims at preparing the step of submicron antibacterial silver particles. Further details.

[0015] First, put the degreasing and water-washed Mg-Nd-Zn-Zr magnesium alloy sample together with a silver nitrate solution with a silver nitrate concentration of 20 g / L into a high-temperature-resistant glass reaction vessel, and the treated magnesium The alloy sample is suspended above the...

Embodiment 2

[0019] The operating steps of this embodiment are basically the same as in Embodiment 1, specifically:

[0020] First, put the degreasing and water-washed Mg-Nd-Zn-Zr magnesium alloy sample together with a silver nitrate solution with a silver nitrate concentration of 20 g / L into a high-temperature-resistant glass reaction vessel, and the treated magnesium The alloy sample is suspended above the solution containing silver ions, and the two are not in contact.

[0021] Then, put the reaction container into an oven and turn on the power to heat it. When the temperature reaches 150°C, start timing. After keeping the temperature at 150°C for 90 minutes, the sample is taken out, washed with water and alcohol, and dried to obtain a submicron surface. Magnesium alloy with antimicrobial silver particles.

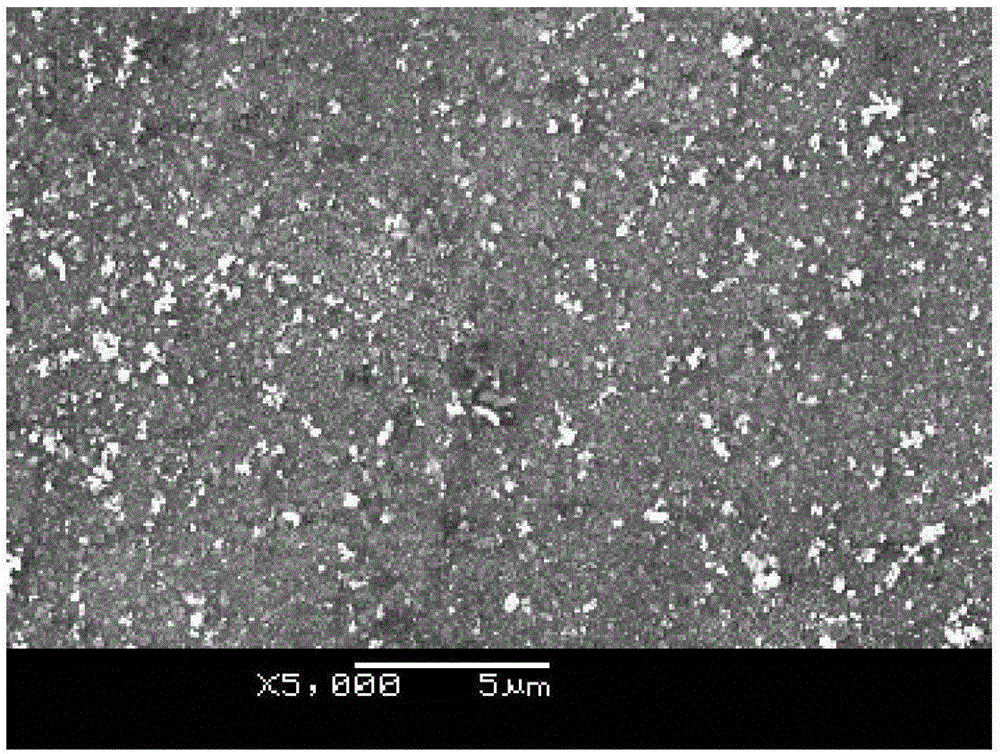

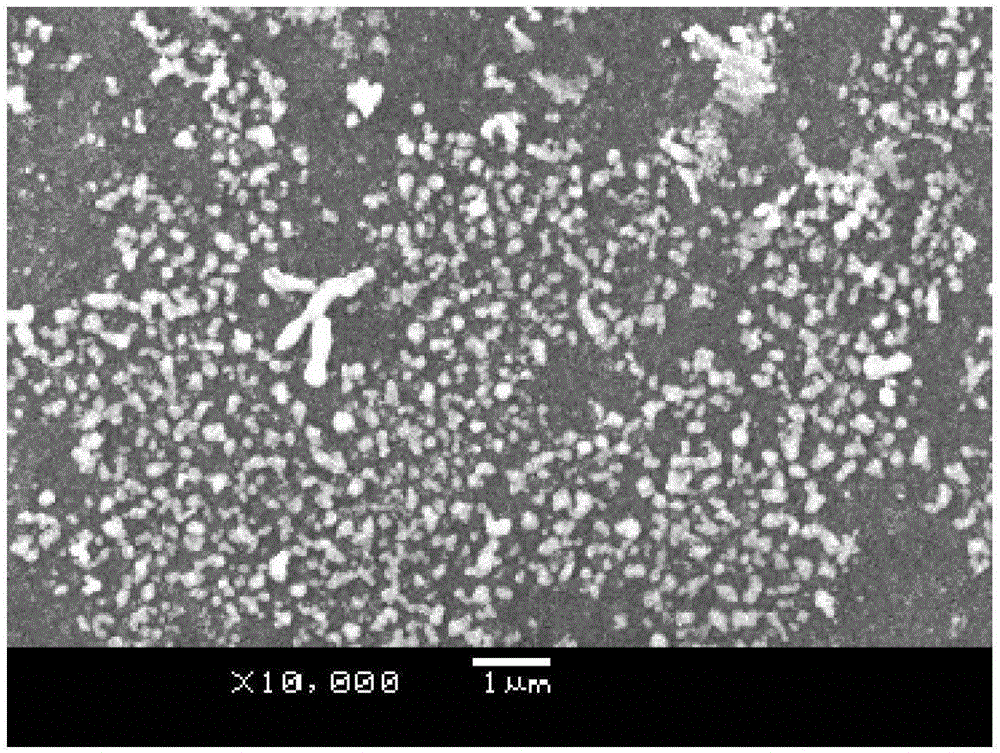

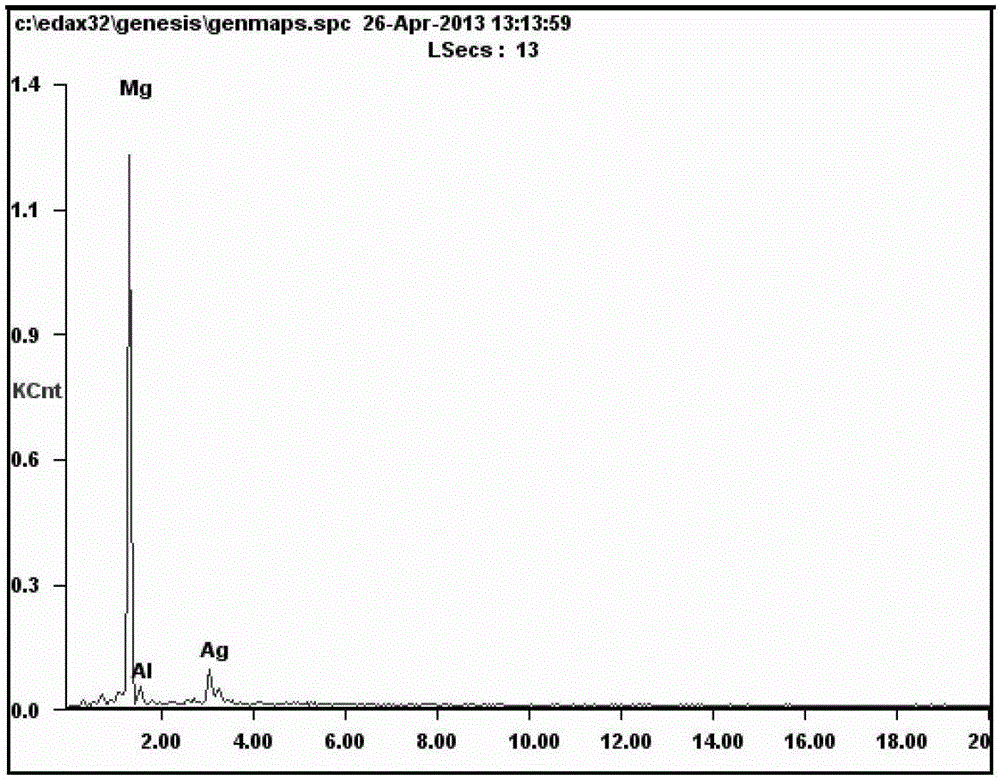

[0022] Observation of the surface morphology of the magnesium alloy prepared by the above method with a scanning electron microscope shows that the surface of the magnesium alloy s...

Embodiment 3

[0024] The operating steps of this embodiment are basically the same as in Embodiment 1, specifically:

[0025] First, put the degreasing and water-washed Mg-Nd-Zn-Zr magnesium alloy sample together with a silver nitrate solution with a silver nitrate concentration of 30 g / L into a high-temperature-resistant glass reaction vessel, and the treated magnesium The alloy sample is suspended above the solution containing silver ions, and the two are not in contact.

[0026] Then, put the reaction container into an oven and turn on the power to heat it. When the temperature reaches 200°C, start timing. After keeping the temperature at 200°C for 30 minutes, the sample is taken out, washed with water and alcohol, and dried to obtain a surface with a submicron surface. Magnesium alloy with antimicrobial silver particles.

[0027] Observing the surface morphology of the magnesium alloy prepared by the above method with a scanning electron microscope shows that many submicron white parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com