Preparation method of pure silver nanowire

A silver nanowire, pure technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as limited application, difficult removal of silver nanowires, affecting the conductivity of silver nanowire networks, etc. , to achieve the effect of good conductivity and light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

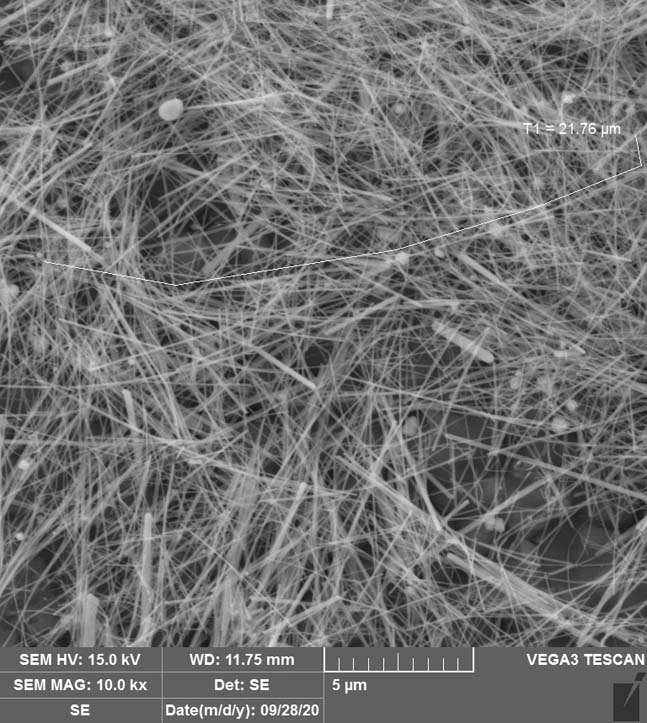

[0027] Weigh 0.68g of silver nitrate (sieved through 20-100 mesh) and dissolve it in 10ml of anhydrous ethylene glycol, the concentration of silver nitrate is 0.4mol / L, weigh polydiene dimethyl ammonium chloride solution, its molecular weight It is 100000-200000, make polydiene dimethyl ammonium chloride quality be 0.16g, add anhydrous ethylene glycol and make total volume be 10ml, polydiene dimethyl ammonium chloride concentration is 0.1mol / L, in reaction Add 5ml ethylene glycol solution of polydiene dimethyl ammonium chloride to the container, drop 5ml ethylene glycol solution of silver nitrate prepared while stirring, the dropping speed is 2ml / min, magnetically stir the mixed solution at room temperature (Magnetic stirring speed is 500rpm) After 10min, put it into an oil bath pre-heated to 200°C, react under static conditions for 6h, take out the product and cool it at room temperature, and centrifuge at 15000rpm for 5min, then wash it once with acetone, deionize After wash...

Embodiment 2

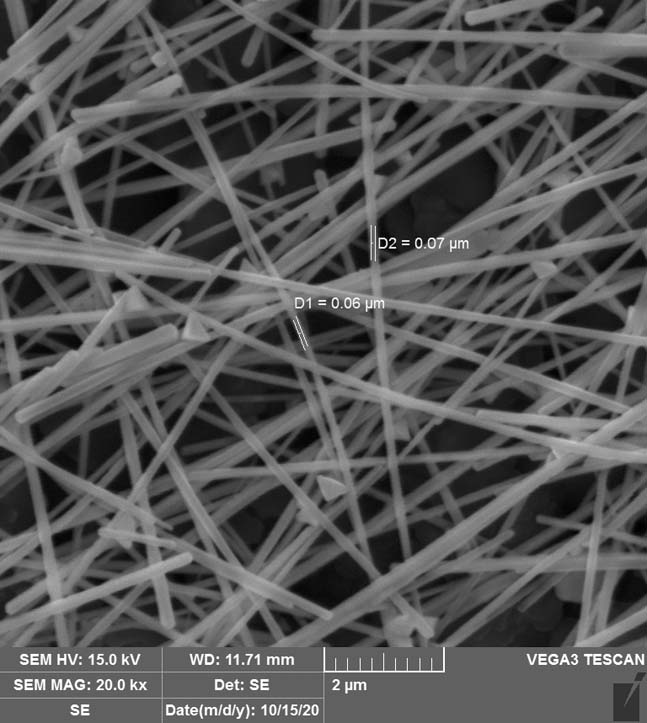

[0029] Weigh 0.068g of silver nitrate (sieved through 20-100 mesh) and dissolve it in 10ml of anhydrous ethylene glycol, the concentration of silver nitrate is 0.4mol / L, weigh polydiene dimethyl ammonium chloride solution, its molecular weight It is 200000-350000, make polydiene dimethyl ammonium chloride quality be 0.128g, add anhydrous ethylene glycol and make total volume be 10ml, polydiene dimethyl ammonium chloride concentration is 0.08mol / L, in reaction Add 5ml of ethylene glycol solution of polydiene dimethyl ammonium chloride to the container, and dropwise add 5ml of prepared silver nitrate solution in ethylene glycol at a rate of 1ml / min while stirring, and magnetically dissolve the mixed solution at room temperature Stir (the speed of magnetic stirring is 350rpm) for 15min, put it into an oil bath pre-heated to 180°C, react for 8h under static conditions, take out the product and cool it at room temperature, and centrifuge at 10000rpm for 10min, then wash it with acet...

Embodiment 3

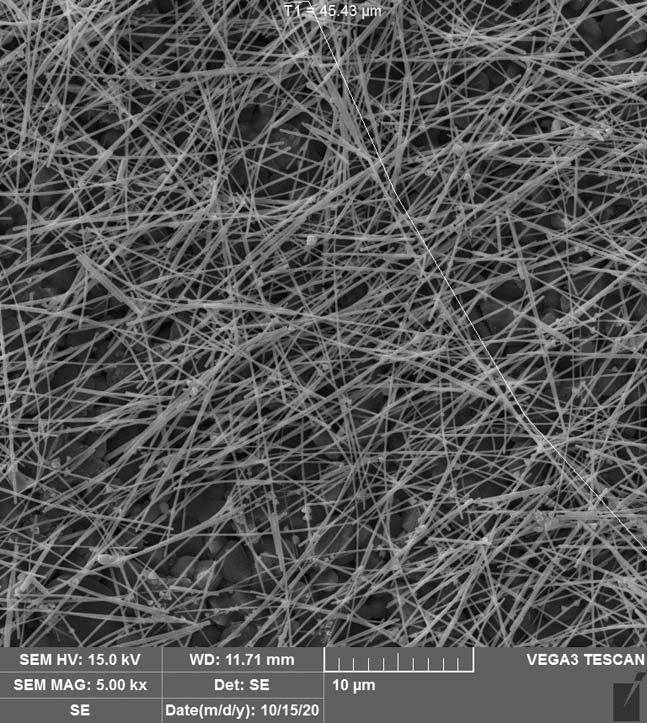

[0031] Weigh 0.068g of silver nitrate (sieved through 20-100 mesh) and dissolve it in 10ml of anhydrous ethylene glycol, and dissolve and prepare it by ultrasonic. The ultrasonic time is 3-5min, the ultrasonic frequency is 40KHz, and the concentration of silver nitrate is 0.4mol / L; Take polydiene dimethyl ammonium chloride solution, its molecular weight is 350000-500000, make polydiene dimethyl ammonium chloride quality be 0.08g, add anhydrous ethylene glycol and make total volume be 10ml, The concentration of polydiene dimethyl ammonium chloride is 0.05mol / L, mixed by magnetic stirring, and the stirring speed is 100-500rpm; 5ml of ethylene glycol solution of polydiene dimethyl ammonium chloride is added in the reaction vessel, While stirring, add 5ml of prepared silver nitrate ethylene glycol solution dropwise at a rate of 3ml / min. Stir the mixed solution magnetically at room temperature (the speed of magnetic stirring is 600rpm) for 20min and then put it into a pre-heated to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com