Lacquer-removing method for outlet head of electric appliance repairing coil

A technology for outlet wires and coils, which is applied in the field of electrical appliance repair coil outlet paint removal method, which can solve the problems of volatile use, high price, not convenient and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

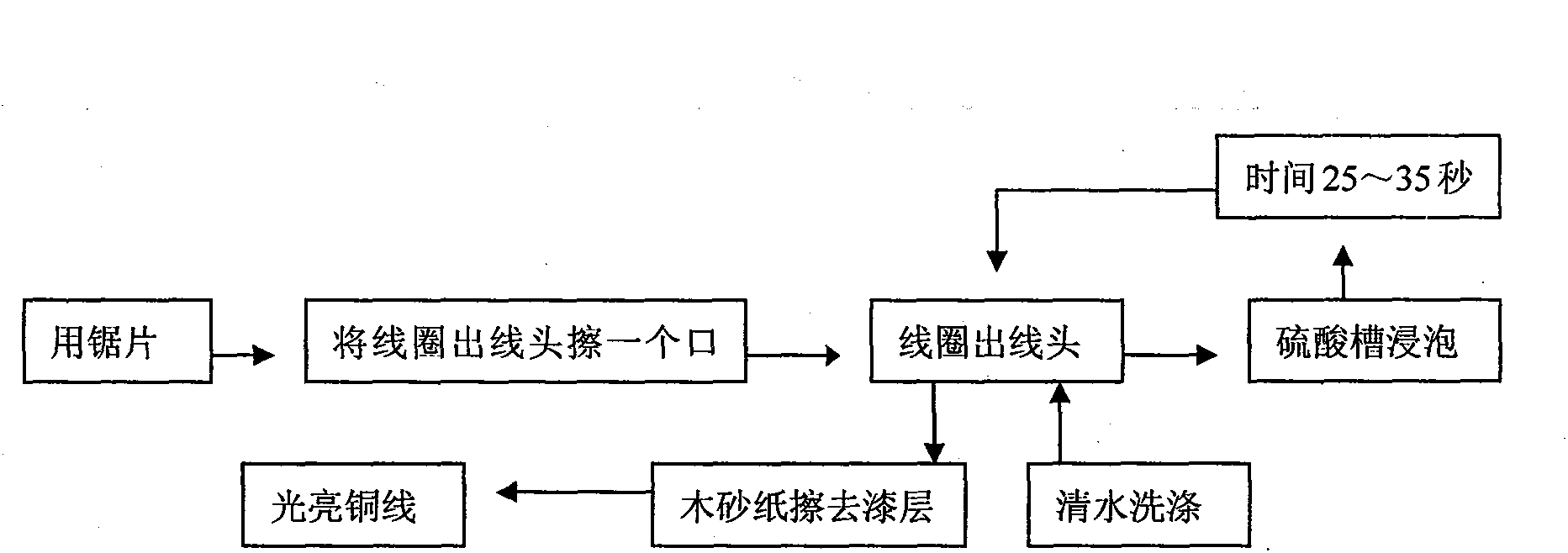

[0016] In the picture, use a saw blade to wipe a hole in the paint layer of the outlet of the motor coil (1), and then soak the outlet of the motor coil in the ceramic sulfuric acid tank (2), so that the sulfuric acid penetrates into the bare copper from the crack of the paint layer The wire starts a chemical reaction (3), soak for 25-35 seconds (4), take out the motor outlet (5), wash the motor outlet (6) with clean water, wipe off the paint layer with wood sandpaper (7), the paint layer is completely Come off and show the bright copper wire head (8), carry out next step welding process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com