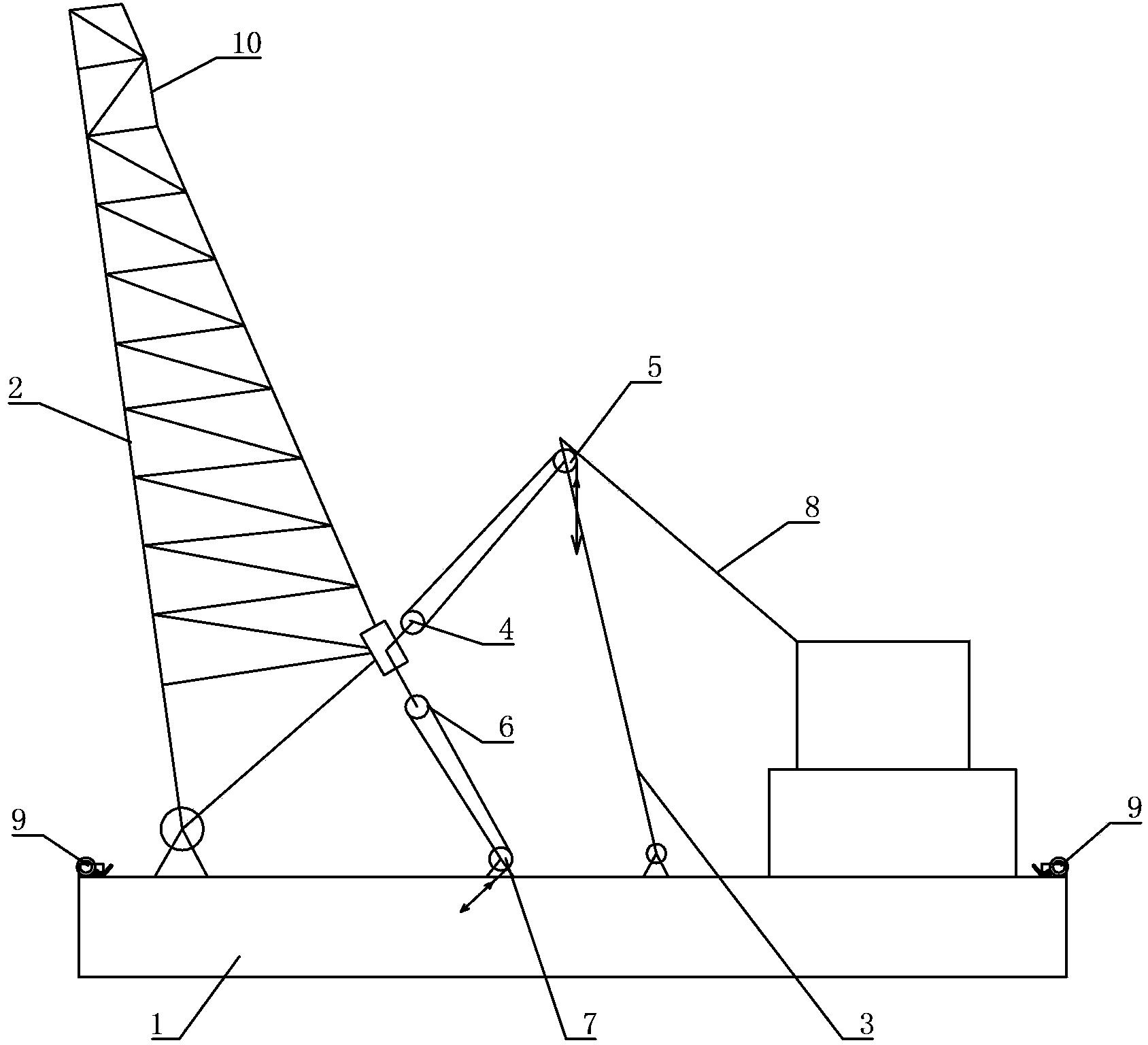

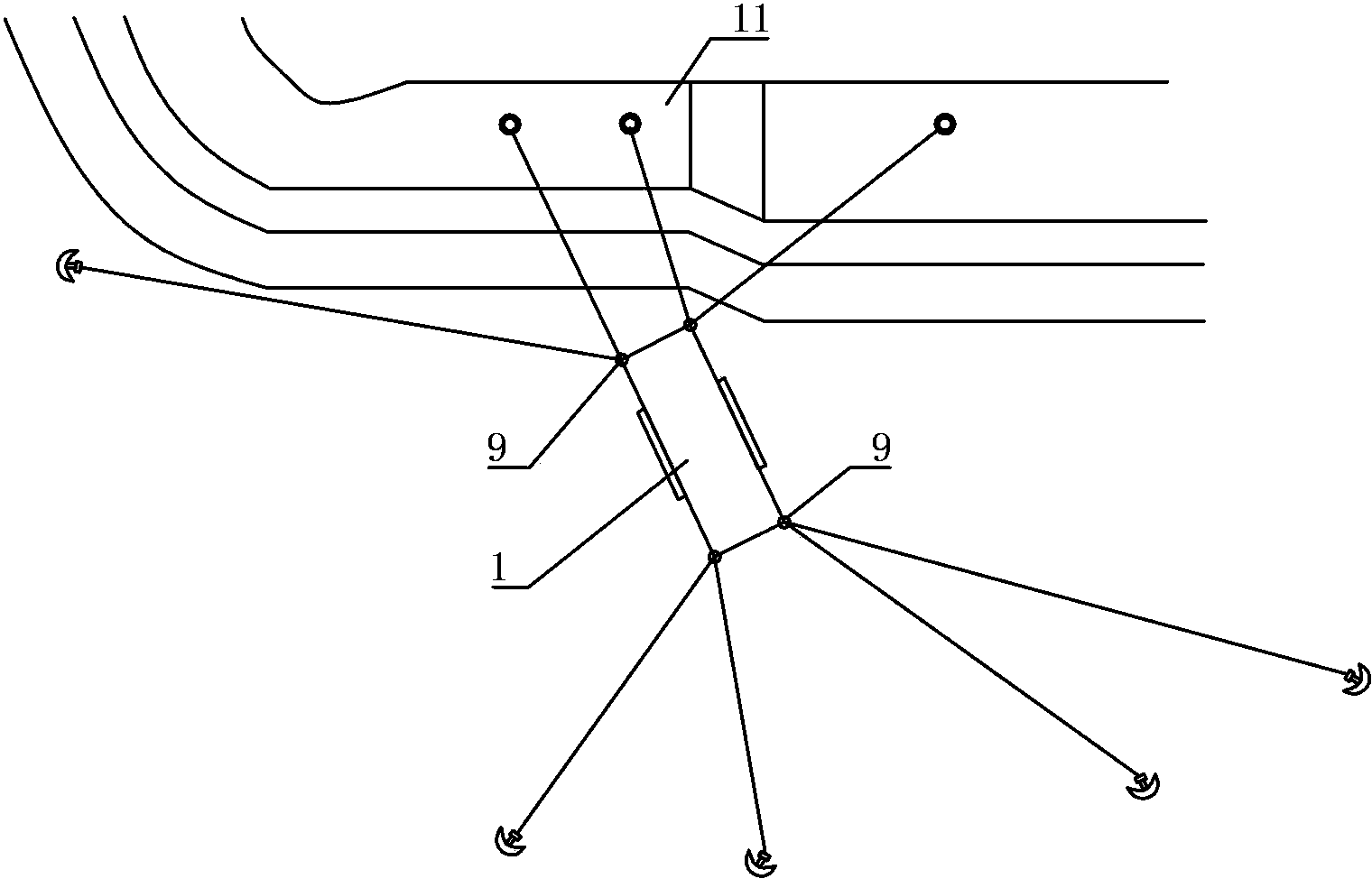

Pile driving mechanism for pile sinking at overwater contracted shallow water area

A technique of sinking piles in shallow waters, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as inapplicability, frequent changes, and affecting the normal entry and exit of ships in waterways and harbor basins, so as to ensure safety, reliability, and flexibility sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The new approach bridge project for the 2# berth of Hainan Refining and Chemical Wharf is a hydraulic wharf renovation project. The main construction contents include: approach bridge pier, conversion platform and Φ1400 steel pipe pile foundation. There are 58 steel pipe pile foundations in the bridge approach project. Steel pipe piles with a diameter of 1400mm are used. The length of a single pile is 56-66.5m. , 5:1, 5.5:1, 6:1, 6.5:1, 8:1, 9:1 nine types. The material of the steel pipe pile is Q345B, the wall thickness of the upper part (L1 section) of the pipe pile is 24mm, and the wall thickness of the lower part (L2 section) is 22mm.

[0017] In view of the fact that the slope of most steel pipe piles is 3:1, the vertical slope of steel pipe piles is small, and the torsion angle changes a lot, the traditional piling barge is generally difficult to drive, and the safety and reliability of construction cannot be guaranteed. Therefore, in order to make the piling bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com