Ultrathin refined ceramic high-thermal-conductivity heating plate and manufacturing method thereof

A manufacturing method and heating plate technology, applied in the direction of ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems of low strength, complex production process, unstable service life, etc., achieve high power density, high heat dissipation efficiency, simplify The effect of the processing step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

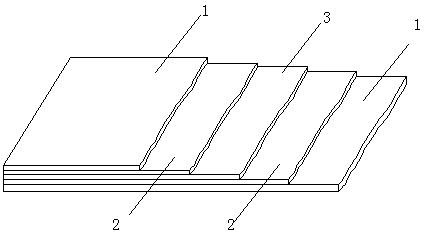

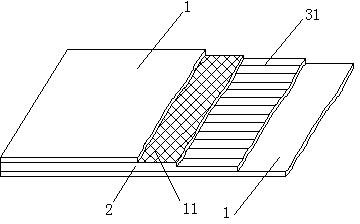

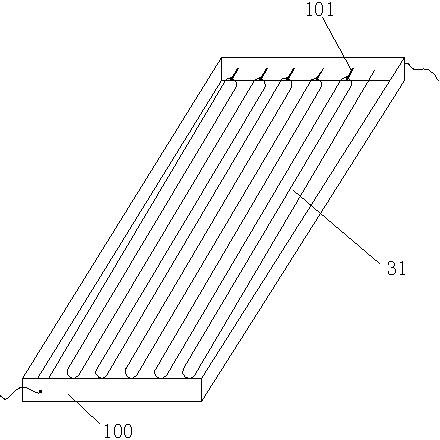

[0038] Such as figure 2 As shown, the heating plate in the present invention includes a plate-shaped heating core and protective layers 1 respectively arranged on both sides of the heating core. The heating core includes a heating frame 2 and a heating element installed in the heating frame 2. The heating element is reciprocally wound in an "S" shape and the heating wire 31 installed in the heating frame 2. The power should be set according to the relevant requirements of the national standard and the heating core. , to select the cross-sectional area and winding density of the heating wire 31. The material of the heating wire 31 is preferably a nickel-chromium heating wire, and may also be a heating wire of other materials. The heating wire 31 in this embodiment is a flat wire, and the flat wire is wound in a vertical form at the corner, and gradually transitions to be arranged parallel to the surface of the heating element toward the middle. An insulating pad is added on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com