Forced lubricating system of single cylinder diesel

A forced lubrication and diesel engine technology, applied in the direction of engine lubrication, pressure lubricant, lubrication pump pressure lubrication, etc., can solve cylinder liner, piston connecting rod bearing bush, crankshaft journal wear, transmission gear set lubrication loss of oil, pull Cylinder and other problems to achieve the effect of reducing gear meshing noise and oil temperature, improving wear resistance and service life, and avoiding lubrication loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will now be further described in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

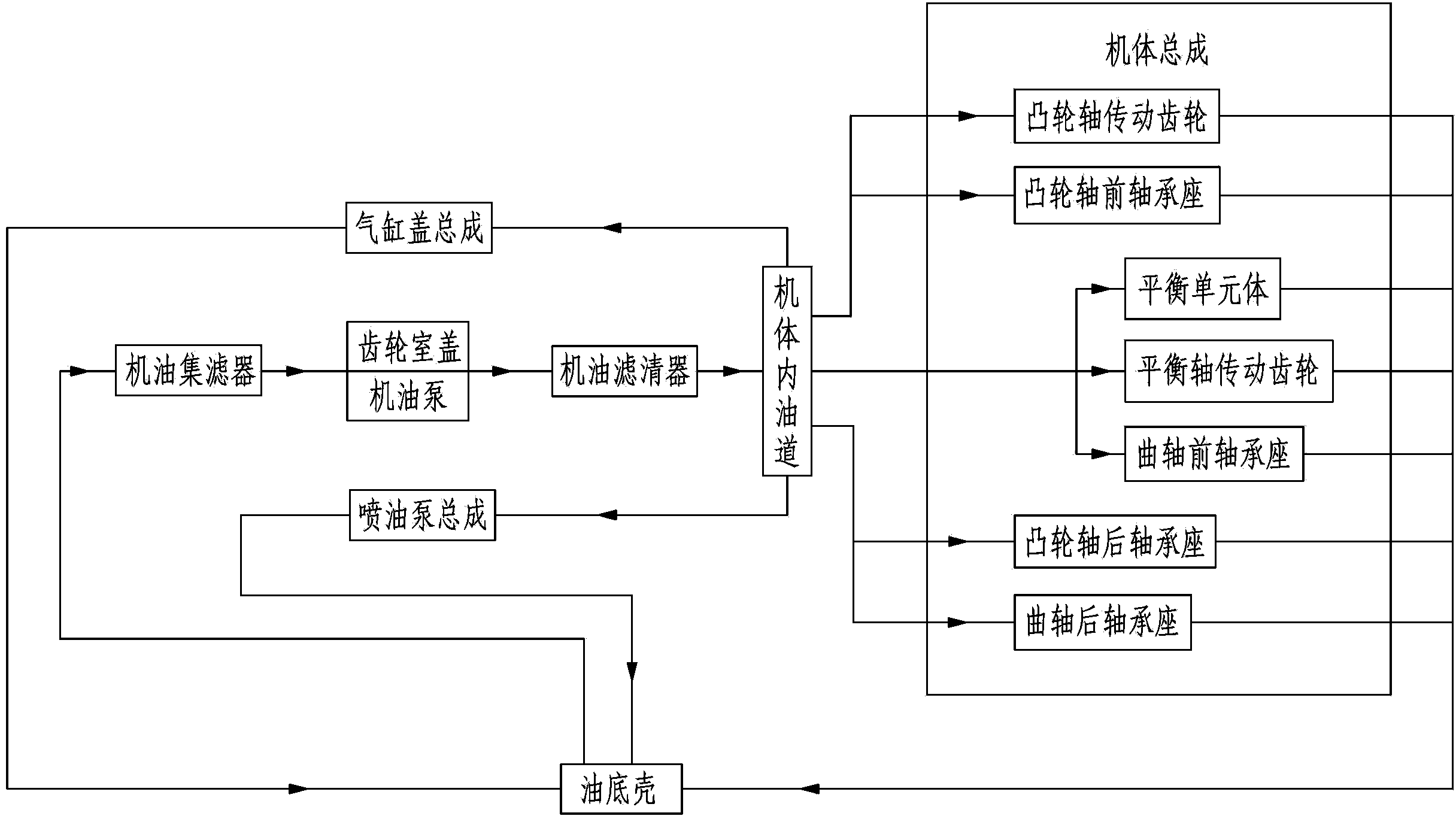

[0010] Such as figure 1 A forced lubrication system for a single-cylinder diesel engine is shown, including an oil pan used for oil storage and heat dissipation, and an oil pump installed in the gear chamber cover. An oil filter is installed in the oil pan, and the oil pump sucks in oil through the oil filter. Engine oil, the outlet of the oil pump is connected to the oil filter. After the oil filtered by the oil filter enters the oil passage in the body, it is forcibly sent to the fuel injection pump assembly, the cylinder head assembly, the body assembly, and the fuel injection pump assembly. The oil return ports of the assembly, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com