Deep sea floating hose

A kind of rubber hose, deep sea technology, applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc., can solve the problems of high operating cost, short service life, and the hose is easily broken and damaged, so as to improve the adaptable life and improve the The effect of damage tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

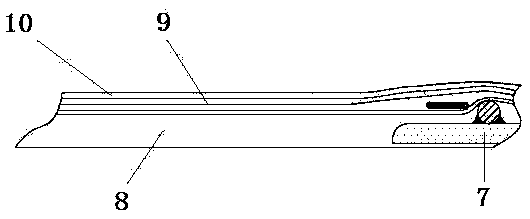

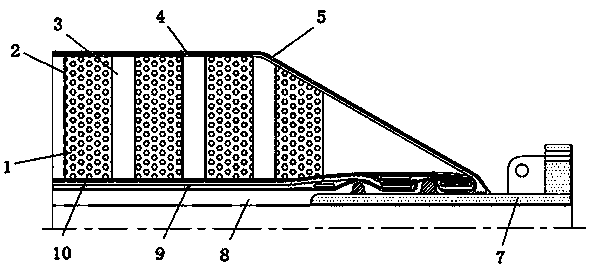

[0020] See Figure 1-2 , the specific structure of the deep sea floating hose is as follows:

[0021] The pressure-bearing part is provided with the inner pipe pressure-bearing layer 9 of the main frame, which must withstand the deep sea pressure of several thousand meters. Therefore, the inner pipe pressure-bearing layer 9 is made of aramid and nylon high-strength composite materials (materials provided for the existing market), that is, made of The high strength and good flex resistance aramid and nylon composite materials are wound according to the designed winding angle to ensure the changing elongation and bending performance of the hose during use. It makes the rubber hose not easy to be broken and damaged when working. The metal connectors 7 that are embedded at both ends of the rubber hose to connect with the deep-sea ship or equipment. It is integrated with high elastic modulus rubber and vulcanized at high temperature.

[0022] A wear-resistant layer 8 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com