Method for automatically measuring and testing sound field of complete anechoic chamber and standard device

A technology of automatic measurement and detection method, which is applied to measurement devices, measurement of ultrasonic/sonic/infrasonic waves, instruments, etc. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

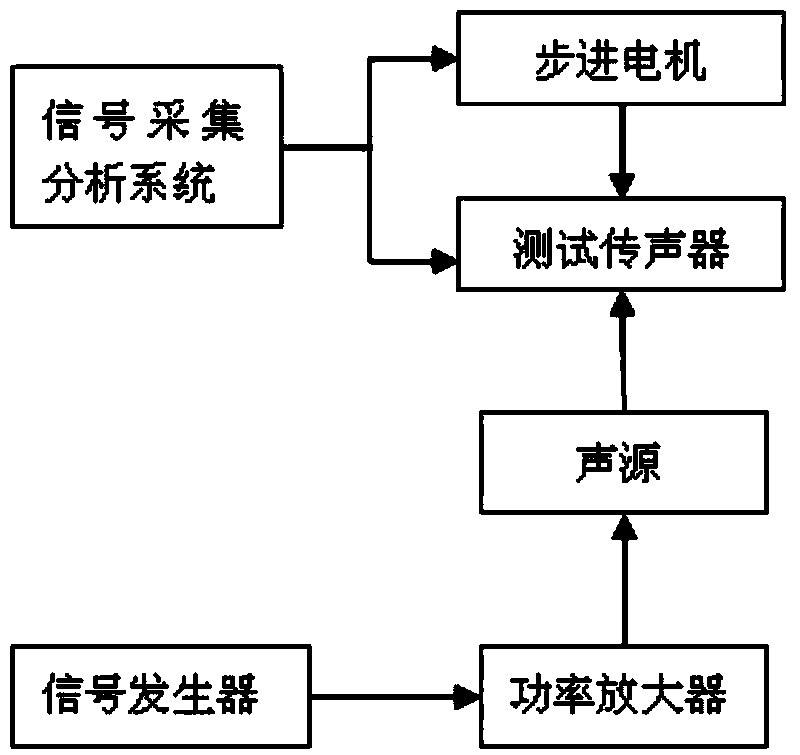

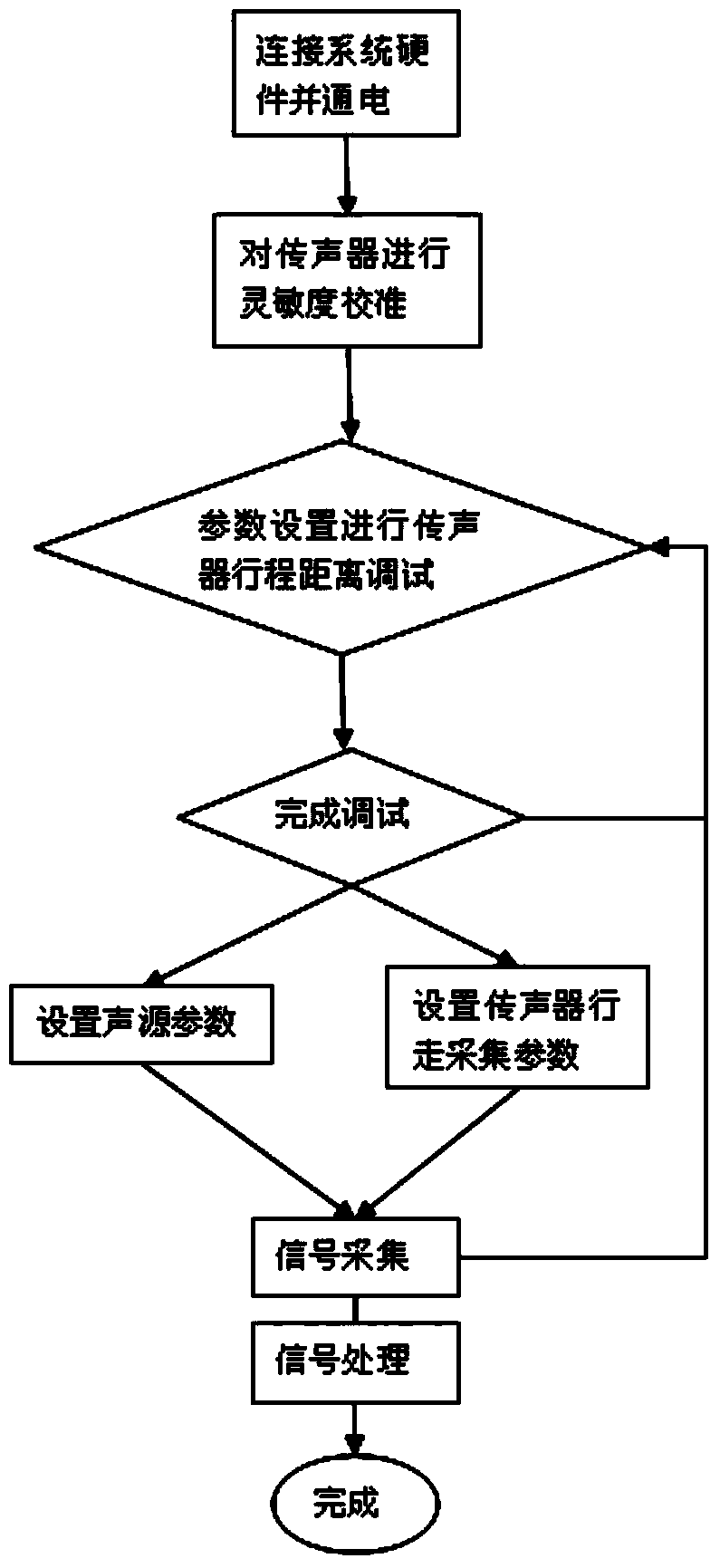

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

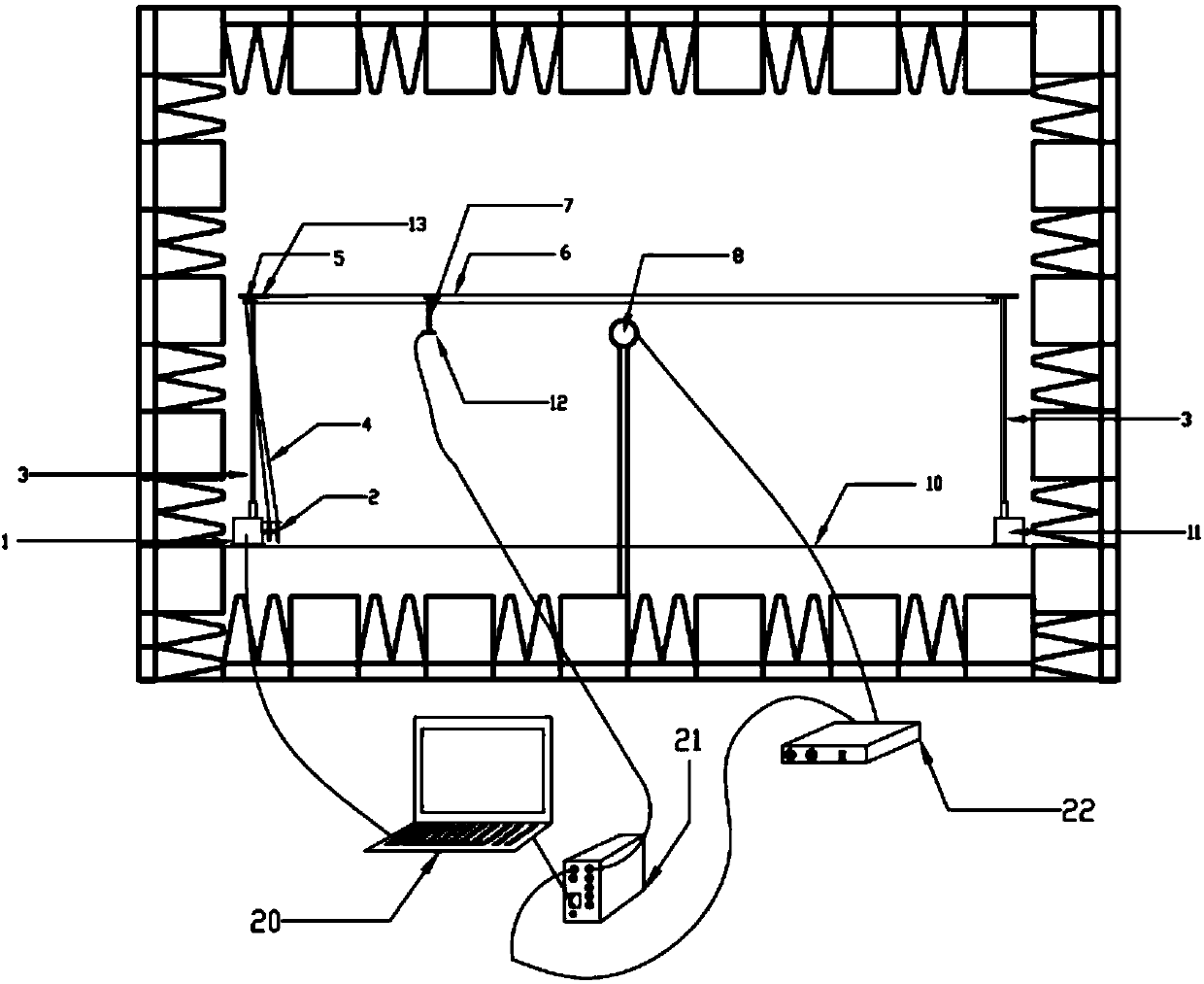

[0032] refer to image 3 , refer to image 3 The sound field automatic measurement and detection device of the full anechoic chamber consists of the main box 1, the traction line runner 2, the telescopic rod 3, the traction fishing line 4, the pulley 5, the fixed steel wire 6, the microphone fixture 7, the sound source 8, the main box 11, It consists of standard microphone 12, I-shaped piece 13, signal acquisition and analysis system 20, signal generator 21, and power amplifier 22, wherein the traction line runner 2 is composed of two runners placed in parallel and turned to the opposite direction, and fixed on the main box by a motor 1 above; two telescopic rods 3 are respectively fixed on the main frame 1 and the main frame 11, and the pulley 5 is fixed on the telescopic rod 3 through the I-shaped piece 13; The rods are fixed to form two horizontal linear guide rails; the microphone clamp 7 is used to fix the microphone 12 and is connected with the fixed steel wire 6 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com