Quality tracing system and method of expansion valves

A technology of traceability system and expansion valve, which is applied in the field of traceability system, can solve the problems of low degree of informatization, large differences in production processes, and no consideration of expansion valve manufacturers, etc., and achieve high adaptability and universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

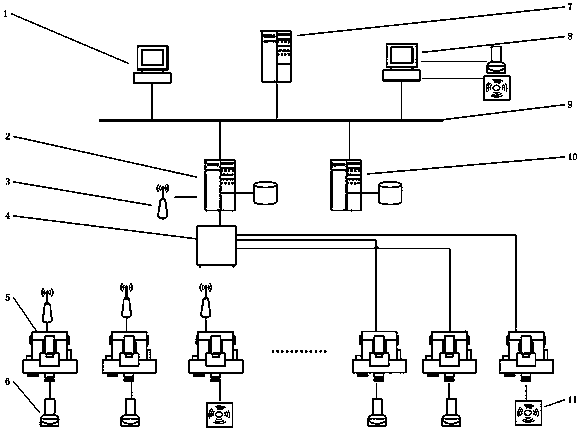

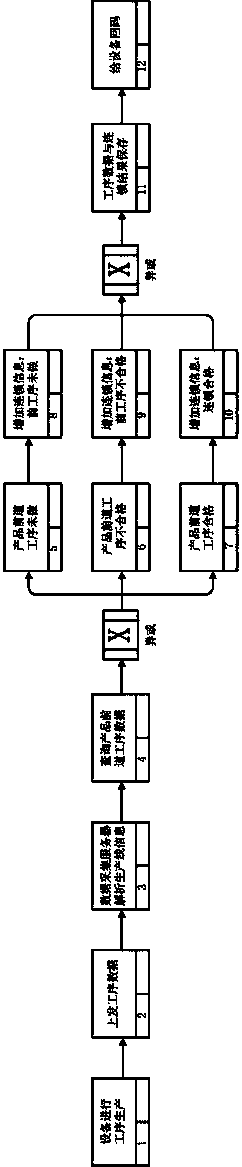

[0020] Such as figure 1 As shown, the system of the present invention includes five hosts, and the five hosts are respectively data acquisition server 2, data operation server 1, product confirmation server 8, WEB server 7 and data redundancy server 10, each host and each process on the expansion valve production line The equipment 5 is connected to each other. For each expansion valve production line, each host computer stores the same production line Excel configuration table. The five hosts call the information in the production line Excel configuration table. The production line Excel configuration table includes various process production detection parameters, The number of stations corresponds to the process parameter information including the communication process number and the chain process number of the process equipment 5. The communication process number cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com