Digital direct-current speed regulating system of electric excavator

An electric excavator, DC speed regulation technology, applied in the direction of excitation or armature current control, can solve the problems of low dynamic efficiency, high energy consumption, high failure, and achieve the effect of reasonable design and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

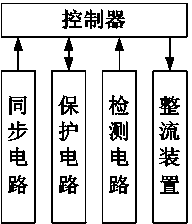

[0015] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0016] A digital DC speed control system for an electric excavator, including a controller, a synchronous circuit, a protection circuit, a detection circuit and a rectifier, the detection circuit includes a speed detection circuit and a current detection circuit, the controller is connected to the synchronous circuit, and the The protection circuit is connected to the controller, the detection circuit is connected to the controller, and the controller is connected to the rectifying device. The speed detection circuit uses a pulse encoder; the current detection circuit uses a Hall sensor; the controller uses a TMS320LF2407A controller.

[0017] combine figure 1 , explain the working principle of the present invention:

[0018] In order to maintain a strict phase relationship between the trigger pulses of each phase of the three-phase fully-control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com