Spray device for sprayer

A technology of spraying device and sprayer, which is applied in the direction of spraying device, device for catching or killing insects, application, etc., can solve the problems of low work efficiency, high labor intensity, manual swing nozzle, etc., achieve simple structure and improve work efficiency , the effect of spraying medicine evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

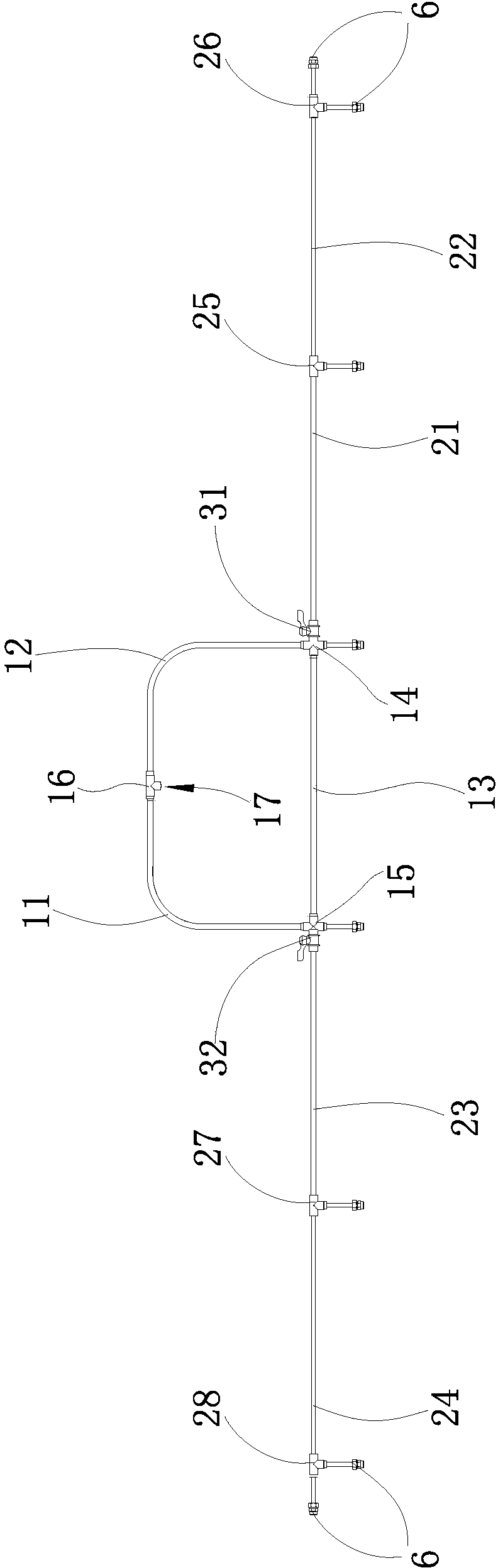

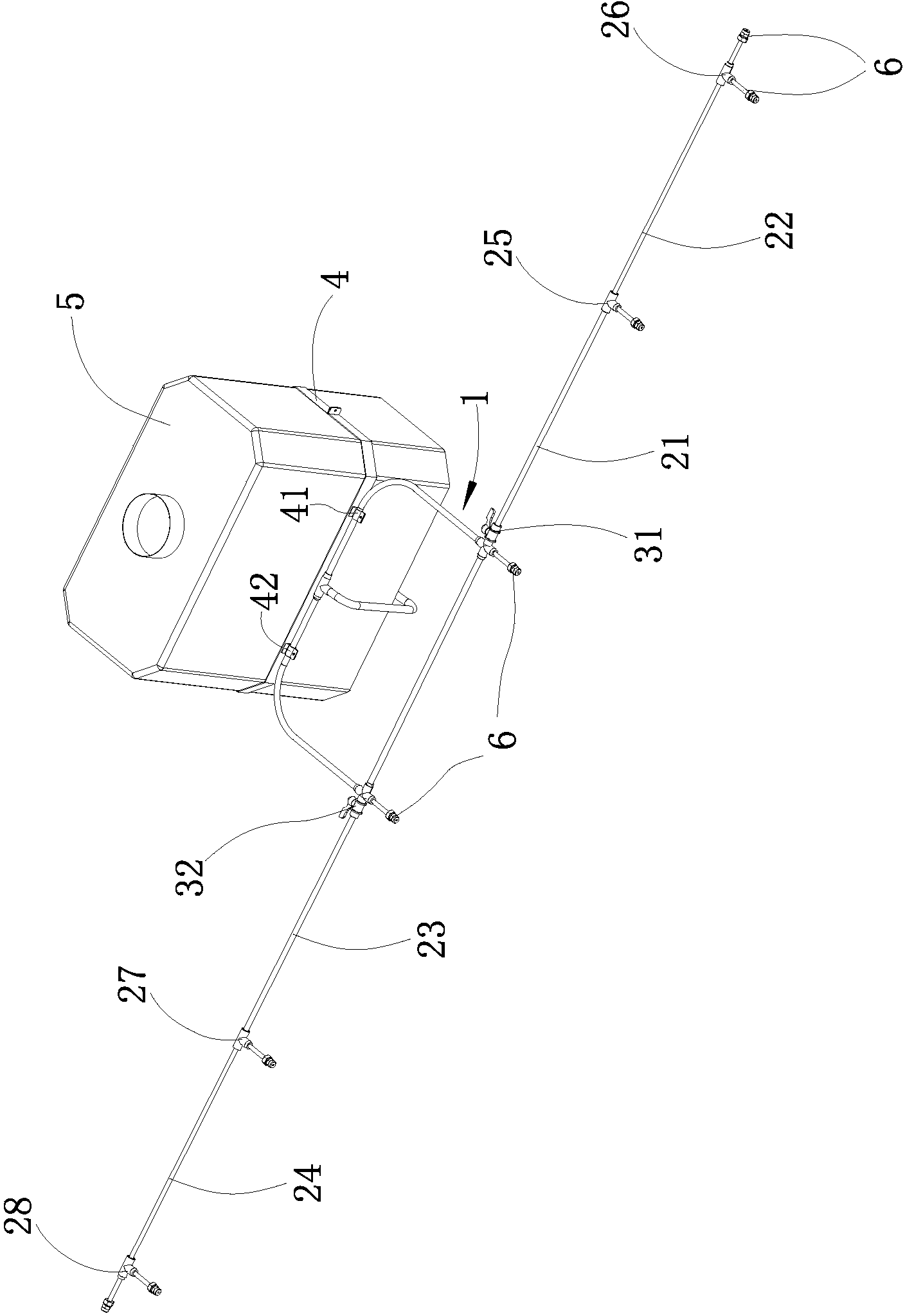

[0014] Such as figure 1 Shown:

[0015] The device includes a support pipe 1, four extension pipes and eight nozzles 6; the support pipe 1 includes a first pipe body 11, a second pipe body 12 and a third pipe body 13, and the first pipe body 11 and the second pipe body 12 It is a 90° folded tube, the first tube body 11 and the second tube body 12 are communicated through the first three-way tube 16, and one port of the first three-way tube 16 is the medicine inlet 17, the second tube body 12 and the third tube body The pipe body 13 communicates through the first four-way pipe 14, the third pipe body 13 and the first pipe body 11 communicate through the second four-way pipe 15, and the first pipe body 11, the second pipe body 12 and the third pipe body 13 end to end Connected, the shape of the support pipe 1 is generally square.

[0016] The four extension pipes are respectively the first extension pipe 21, the second extension pipe 22, the third extension pipe 23 and the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com